2-12

Chapter 2 Installation of this Device

2-2-5 Precautions When Attaching FEP Protective Film

* The FEP protective film is optional. If this option is selected, a “Teflon Protective Film

Attachment Manual” will be included, so refer to that document as well.

• Be careful not to tighten the FEP protective film excessively, as the film may become

damaged.

• If the zero point shifts significantly when the pressure-receiving part is attached to the

process side flange, it is conceivable that there is too much grease or that the gasket is

misaligned, so check the attachment conditions for problems.

(1) 3B Flanges

When attaching the pressure-receiving part to the process side flange, follow the steps below

immediately beforehand.

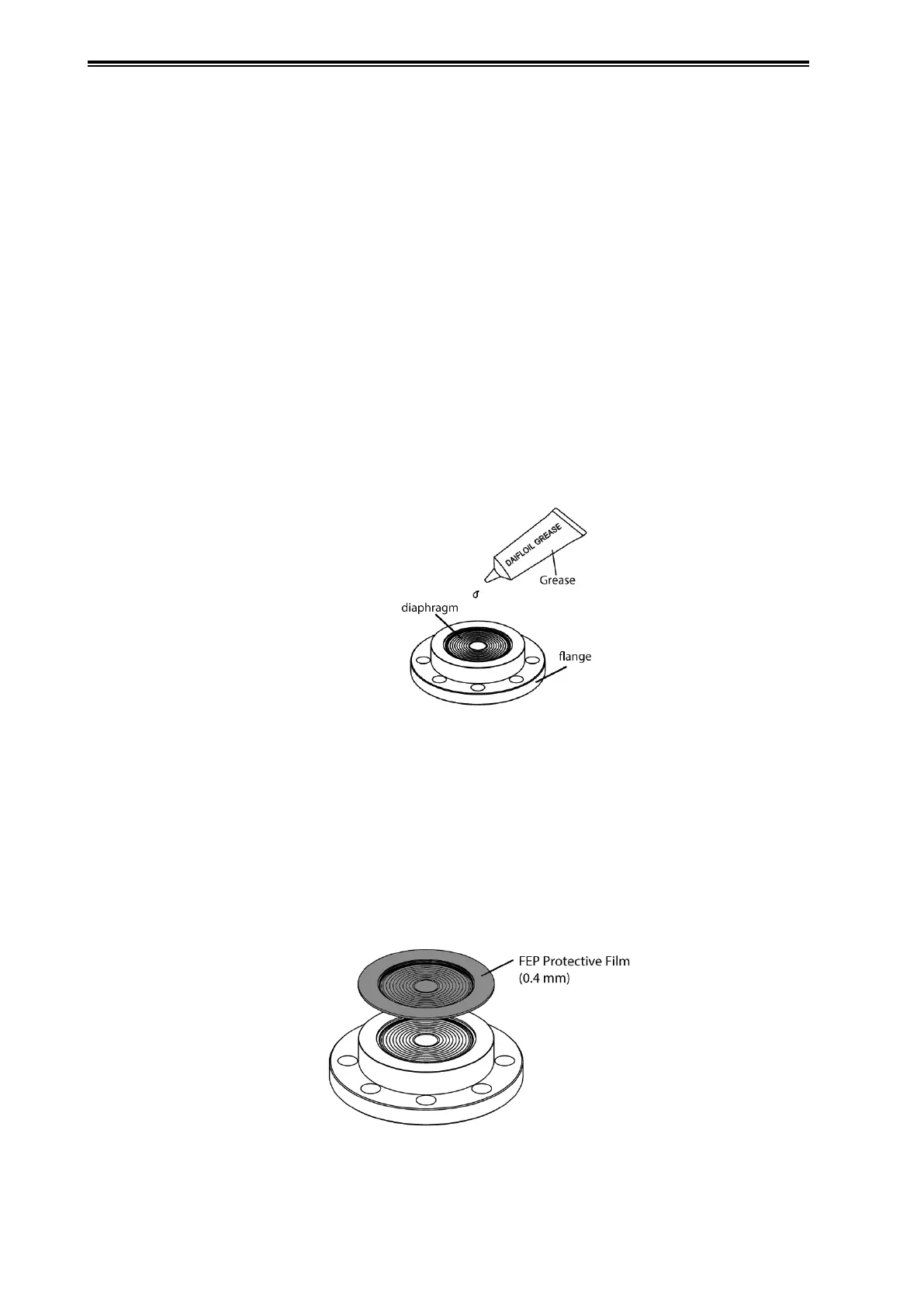

(1) Hold the diaphragm surface of the pressure-receiving part of the transmitter such that it faces

upward.

(2) Apply about 15g of Daiflon grease (about one-third of a tube) to the diaphragm surface, and

spread it across the entire surface with your finger. The average thickness of the grease on the

diaphragm will be about 2mm.

Figure 2-10. Application of Grease

Also be careful of the following during attachment.

• When applying the grease, do not apply excessive force that might deform the

diaphragm.

• Make sure that no air (bubbles) are left in the grease.

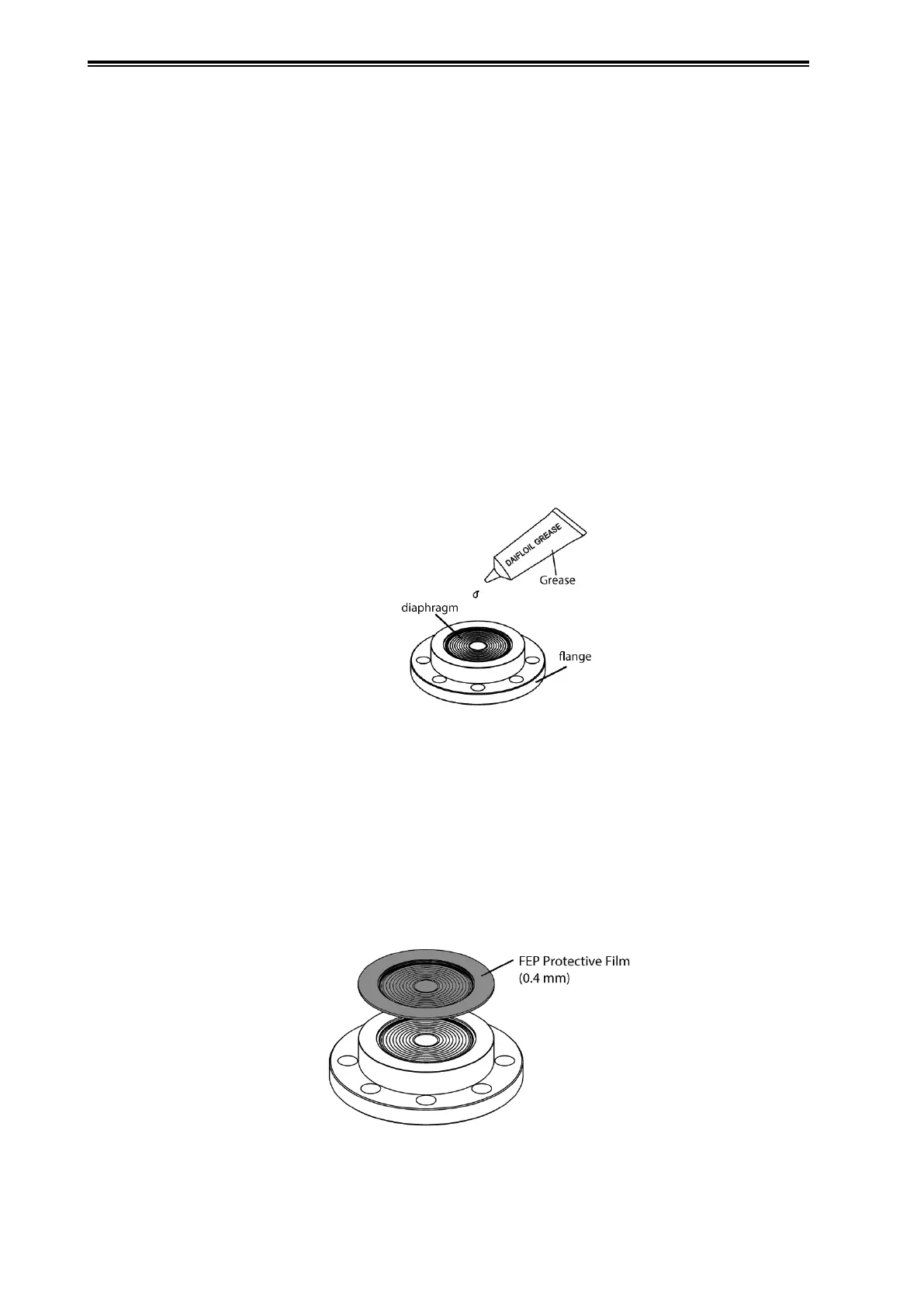

(3) Fit the FEP protective film onto the diaphragm gasket surface.

Figure 2-11. Attachment of FEP Protective Film

Loading...

Loading...