2-9

Chapter 2 Installation of this Device

2-2-4 Connecting the Wetted Part of a Flange Type or Remote Seal Type to the Process

Warning

When installing the product, make sure that the gaskets do not stick out at the connections

with the process (connections between adapter flanges and connecting pipes and flanges).

Also be careful not to forget to close vent and drain plugs. There is a danger that the

measured fluid will leak out and cause scalding and other harmful health effects. If the

measured fluid is harmful to the human body, take safety measures such as wearing

goggles or a mask so that it does not adhere to the skin or the eyes, become inhaled, etc.

Caution

During transport, grasp the flanges and the protective pipes. Grasping the capillary

tubes, letting the flanges hang down, etc., may result in the capillary tubes slipping out of

your hands and the flanges falling, possibly causing injury.

A cover is attached to the diaphragm to protect the surface that connects to the wetted

part. Remove it when attaching to the process. It is not a gasket.

Protective Cover

Protective Pipe

Flange

Example: Remote Sealing

(1) Precautions When Attaching a Flange Type (JTC) Transmitter

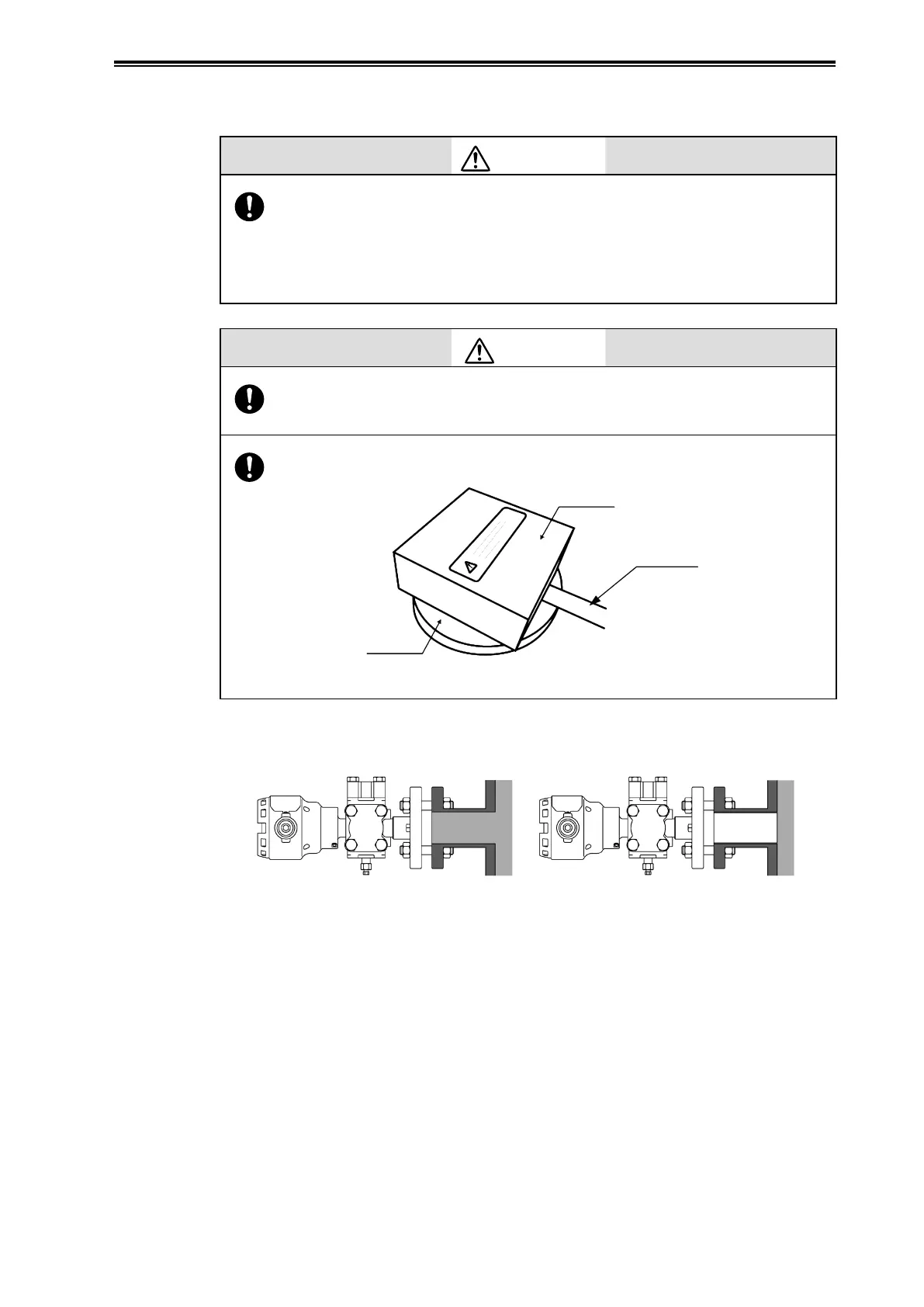

Referring to Figure 2-5., attach the flange to the process.

(Standard Mount Type) (Protruding Type)

Figure 2-5. Attaching Flange Type Transmitter to Tank

• Have on hand the parts necessary for attachment to the process side flange (bolts, nuts, gaskets).

Select these based on the diameter, pressure rating, usage temperature, etc.

• To prevent leaks, tighten the bolts equally firmly.

In actual practice, to tighten bolts with an appropriate torque, various factors should be taken

into account, such as the bolts' material, the type and dimensions of the gasket, the type and

pressure of measured fluid, and the shape of the companion flange. Approximate tightening

torques are shown below.

Loading...

Loading...