2-10

Chapter 2 Installation of this Device

(2) Precautions When Attaching the Pressure-Receiving Portion of a Remote

Seal Type (JTE/JTH/JTS) Transmitter

• For the JTE model, in order to lessen the effects of temperature differences in the surroundings,

bundle together the high pressure side and low pressure side capillary tubes. In addition, fasten the

capillary tubes so that they do not move around due to wind, vibration, etc. Tie up and fasten excess

capillary tubes. When doing so, be careful not to bend the tubes excessively beyond their bend radius.

• For JTH and JTS models, fasten the flange and capillary tubes securely in a location where

ambient temperature variation is low and there is no vibration.

• Attach the process side flange using mounting bolts and gaskets. To prevent leaks, tighten the

bolts equally firmly. See page 2-6 for tightening torque reference values.

• Prepare a flange gasket which is appropriate for the process flange side. When using semi-

metallic or rubber gaskets, select ones which are shaped so as to not come into contact with the

diaphragm of the transmitter.

• Attach the FEP protective film as per section 2-2-5.

* Precautions when selecting 3B flush mount type gaskets

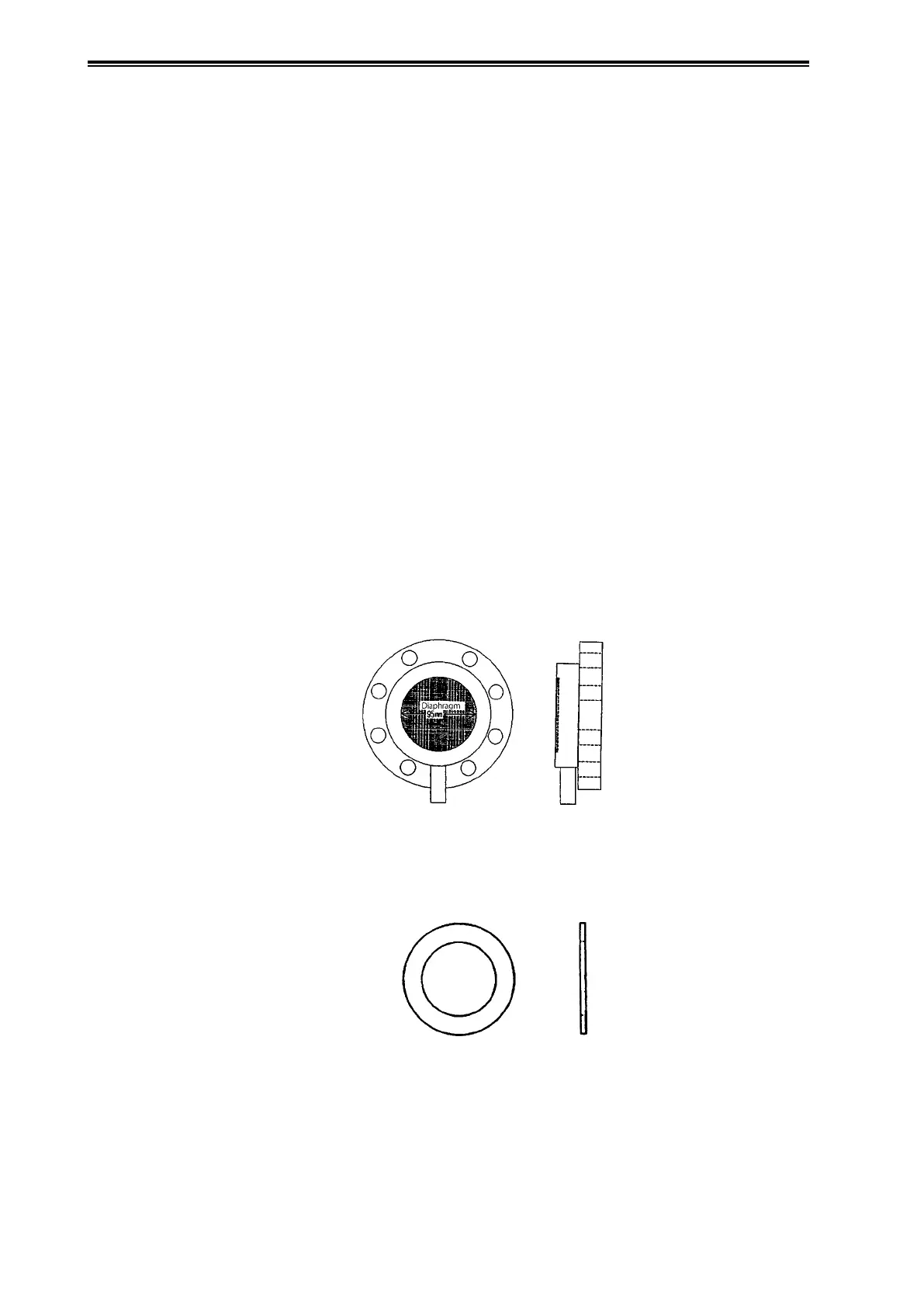

As shown in Figure 2-6, the diaphragm diameter is 95 mm, so if a commercially available

3B gasket is used, it will come into contact with the diaphragm and may cause malfunctions.

Select appropriate materials based on the fluid, the working pressure, the temperature, etc.,

and also be careful of the inside diameter.

• Be careful of the inside diameter of the gasket to be used. The commercial 3B gasket

inside diameter (80-90 mm) is smaller than that of the diaphragm.

Outer dimension : 134 mm

Inside diameter : 98 mm

+2

- 0

ickness: 2 mm

Figure 2-6. 3B Flash Mount Type Diaphragm Diameter

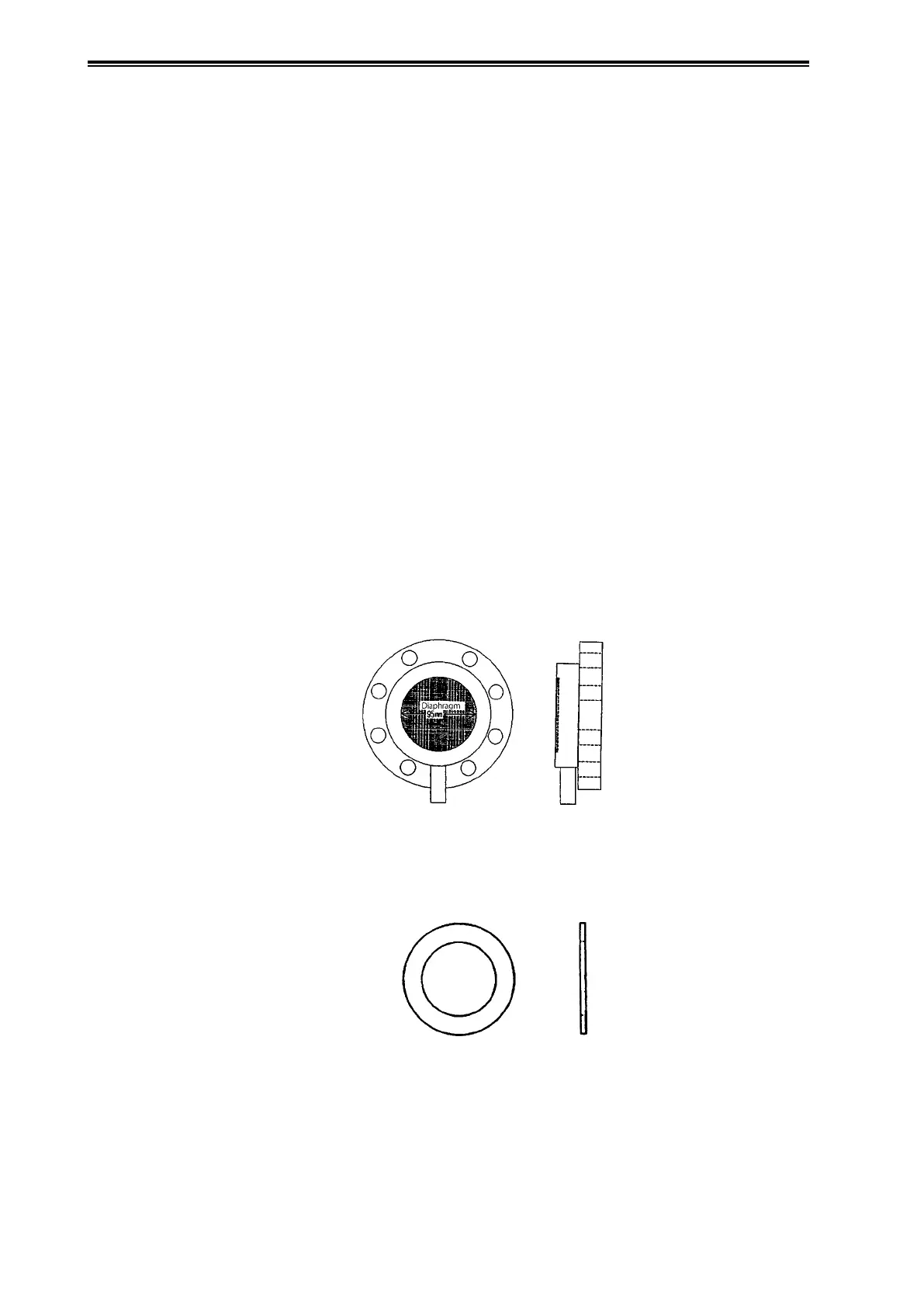

Outer dimension : 134 mm

Inside diameter : 98 mm

+2

- 0

ickness: 2 mm

Figure 2-7. Gasket Selection Example (Dimensions)

• When a gasket wears out, select a new one that does not come into contact with the

diaphragm. If the gasket is made of soft material, it may become deformed when it is

fastened. In addition, the gasket can droop, become warped, etc., so attach the gasket

such that its center lines up with the center of the diaphragm.

Loading...

Loading...