3-59

Chapter 3 Starting and Stopping this Device

3-11 Advanced Diagnostics (optional )

The advanced diagnostics include the pressure frequency index, the standard deviation, and

calculation of the out-of-range pressure event count.

The diagnosis also determines whether the pressure frequency index, standard deviation, and the

out-of-range pressure event count exceed the threshold values. Users can check alarms on the self-

diagnostics status screen in the communicator if the results exceed a threshold. Alarms can also be

checked on the built-in indicator of the transmitter.

3-11-1 Pressure Frequency Index

The pressure frequency index quantifies how often the input pressure goes up and down

(fluctuation) with a number between 0 and 1. The index is calculated from data on the number

of fluctuations during a time period of several minutes. It is possible to detect a change in process

conditions by monitoring changes in this value. For example, the pressure frequency index can be

used for diagnosis of clogged connecting pipes.

For information about diagnosis of clogged connecting pipes, see Appendix B.

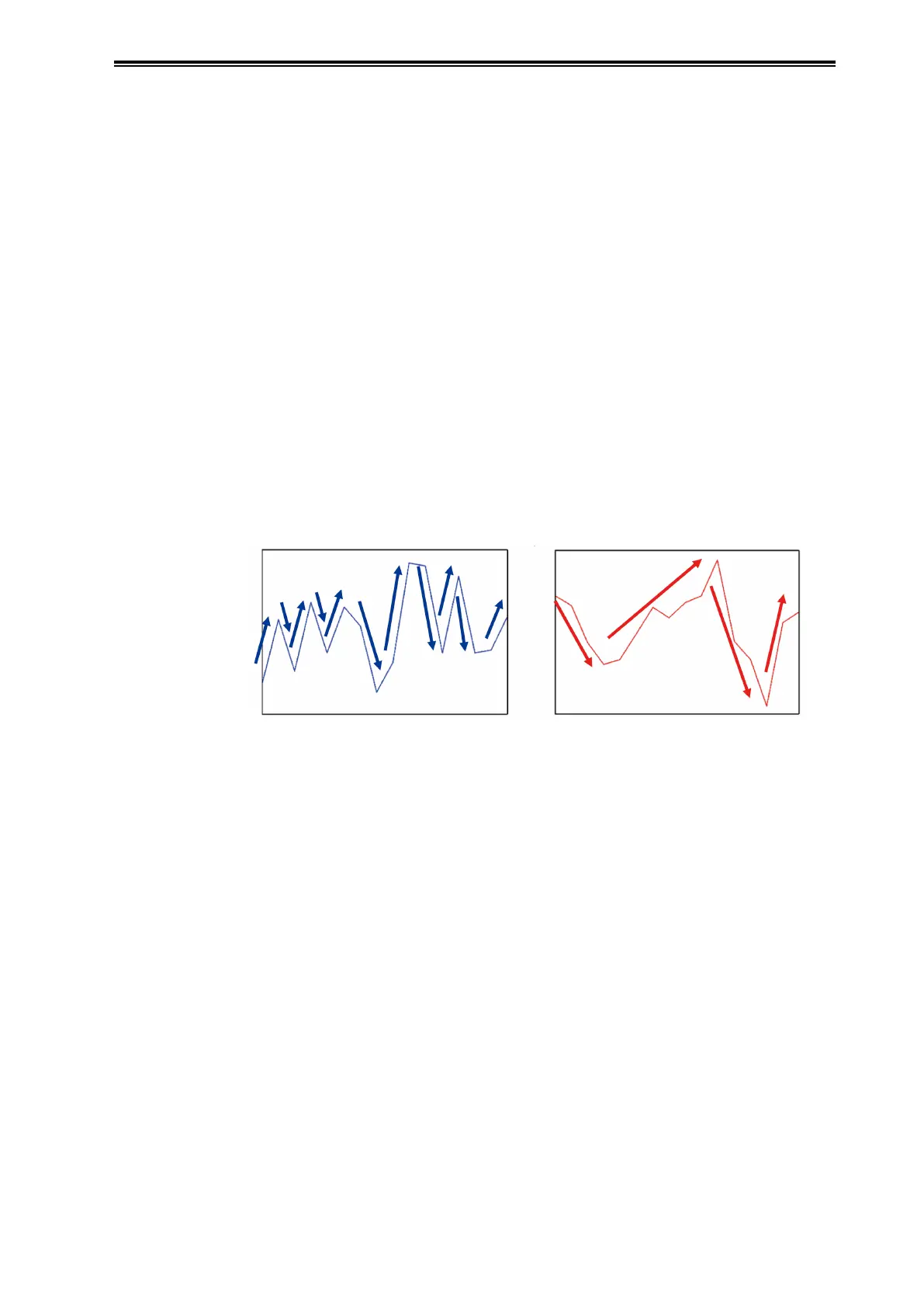

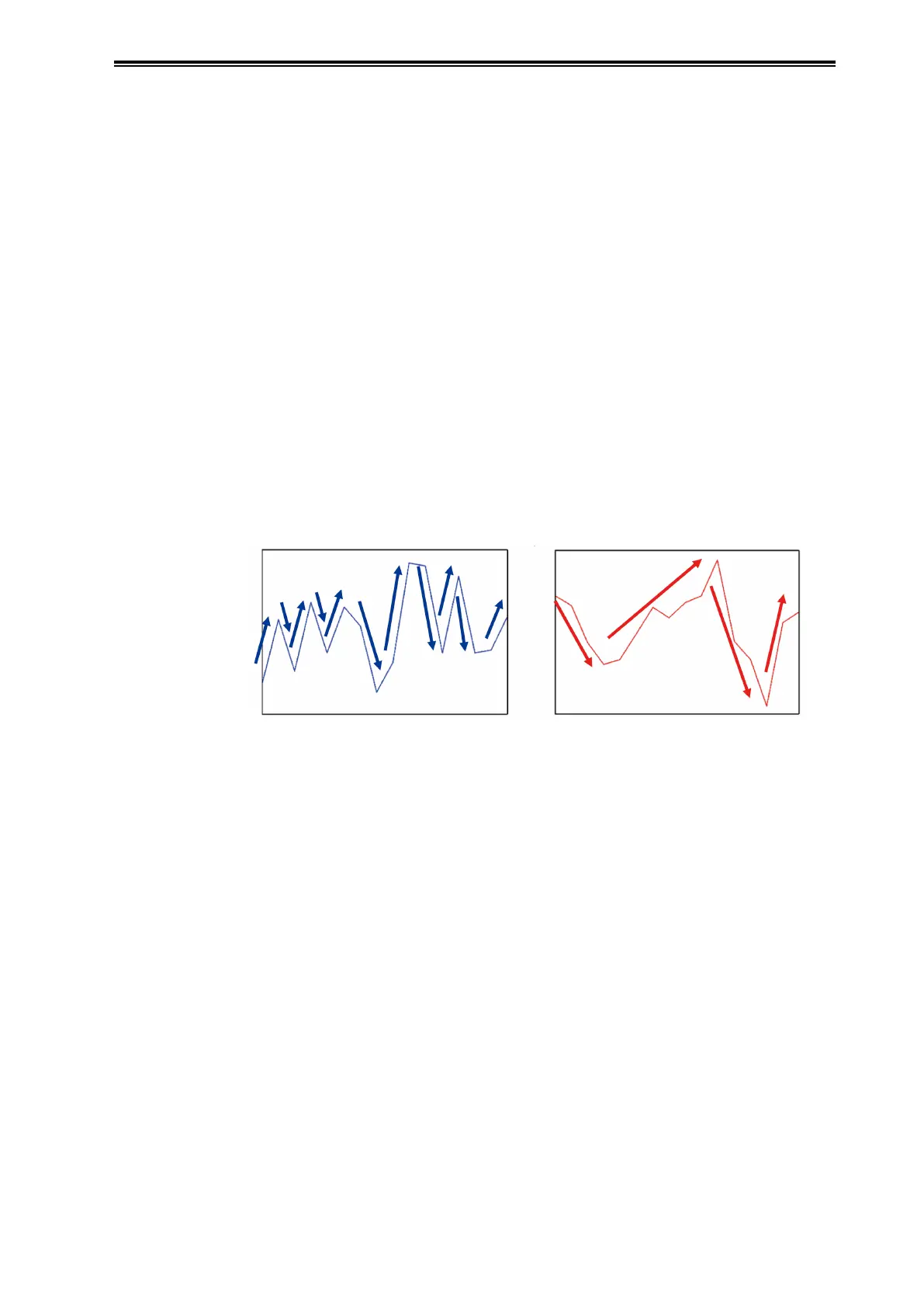

In the practical example shown below, a change in the number of fluctuations of the input pressure

when the process is operating normally and when conditions have changed can be easily seen.

normal conditions changed conditions

(1) Points to note

When using the pressure frequency index, note the following:

The pressure frequency index changes depending on a combination of factors. Thus, it may be

difficult to detect a single abnormality or phenomenon by this index alone.

If the process is in an abnormal state from the beginning, it is not possible to detect a change

caused by abnormal conditions. Carry out the steps described below in (3), “Preparation,” under

normal conditions.

Even if an unexpected abnormality occurs, the pressure frequency index does not necessarily

change immediately. This is because it takes a few minutes to calculate the frequency of the

pressure fluctuation with a high level of accuracy. If an abnormality occurs briefly and conditions

quickly return to normal, the change in the index will be small, and an alarm may not be activated.

If the transmitter is installed in an environment subject to excessive vibration, the pressure

frequency index will be affected. As a result, an error may not be detected or there may be a false

alarm. If the pressure frequency index is used to diagnose clogging of connecting pipes, problems

may not be detected correctly, depending on the process conditions.

Loading...

Loading...