2-34

Chapter 2 Installation of this Device

2-3-3 Liquid Level Measurement Piping (JTD/JTG Model)

Warning

When doing the piping work, ensure that the connections between the connecting pipe

parts and the transmitter and three-way manifold valve are able to maintain a reliable

seal. If sealing is inadequate, there is a danger that the measured fluid will leak out and

cause scalding and other harmful health effects. If the measured fluid is harmful to the

human body, take safety measures such as wearing goggles or a mask so that it does not

adhere to the skin or the eyes, become inhaled, etc.

(1) Piping

(i) Introduction

The method of measuring the liquid level in the tank using a JTD model transmitter differs depending

on whether the tank is open or sealed. In addition, if the tank is sealed, the piping method also differs

depending on whether the gas seal method (dry leg) or the liquid seal method (wet leg) is used.

Measuring the liquid level in the tank using a JTG model transmitter is in general performed on

anopen tank.

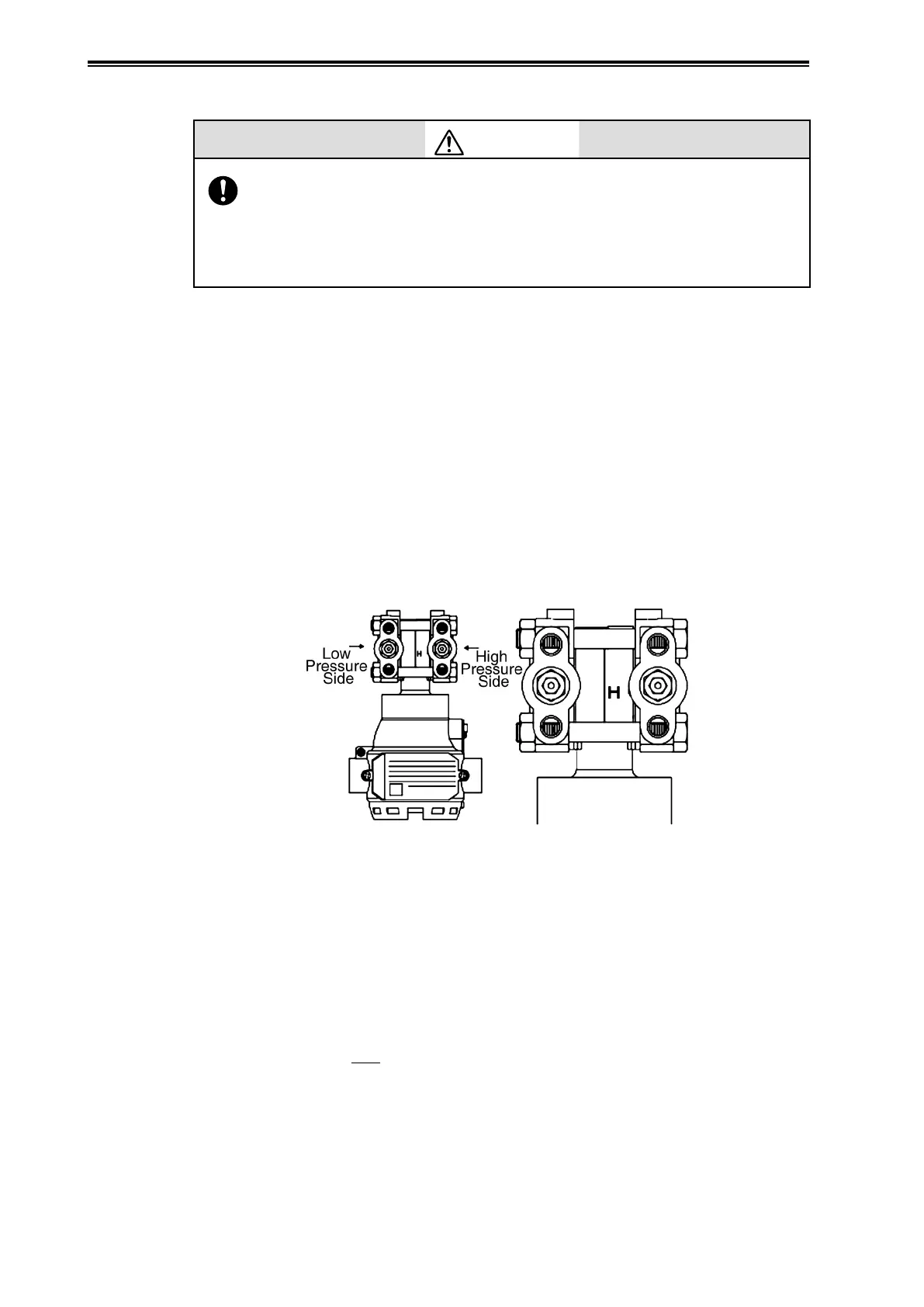

(ii) High pressure side mark on this device

An “H” is displayed on the high pressure side of the main unit of this device to indicate high

pressure, so be sure to check this during piping in order to avoid mistakes. The side without a mark

is the low pressure side.

Figure 2-40. Mark on High Pressure Side of Main Unit

(iii) Caution

In the range that appears on the nameplate at the time of shipping, if the amount of suppression is

more than 1/2 the span, the positions of H and L switch. In that case, H will be on the left side, and

the H mark will be on the rear side. In this case, do the process piping so as to connect the high

pressure to the side without the H stamp.

Example: When range is -50 to +20 kPa

Suppression quantity 50 kPa

Span 70 kPa

50 >

70

= 35 is the result,

2

so the amount of suppression is higher, and thus the high pressure side will be on the left side.

Loading...

Loading...