3-32

Chapter 3 Starting and Stopping this Device

3-5 Measurement Using the JTE Model

At the start of operation, make adjustments while the process is in its actual state.

3-5-1 Liquid Level Measurement

(1) Preparing for Operation

(i) Checking the minimum liquid level (zero position) and zero point input

during input equalization

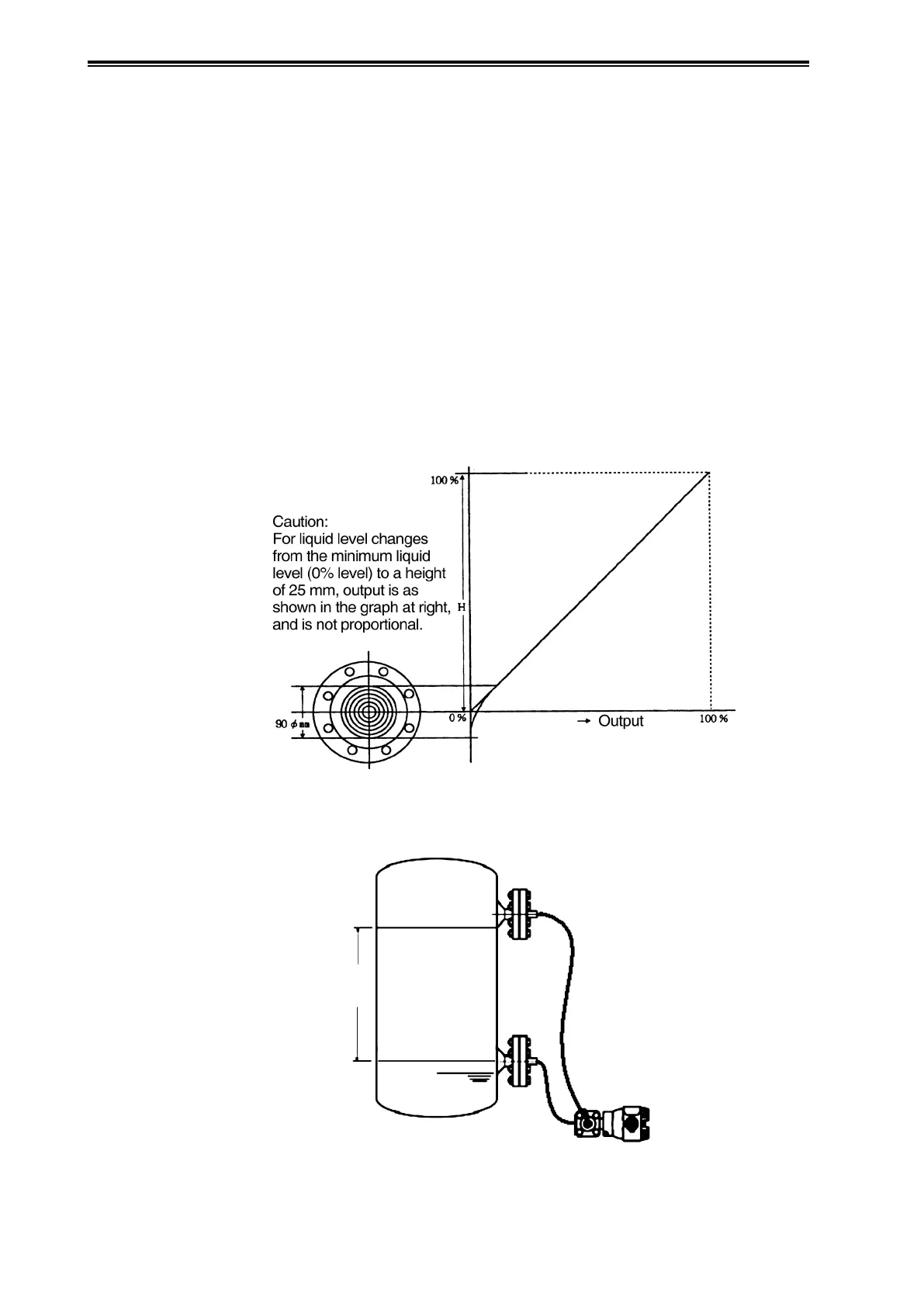

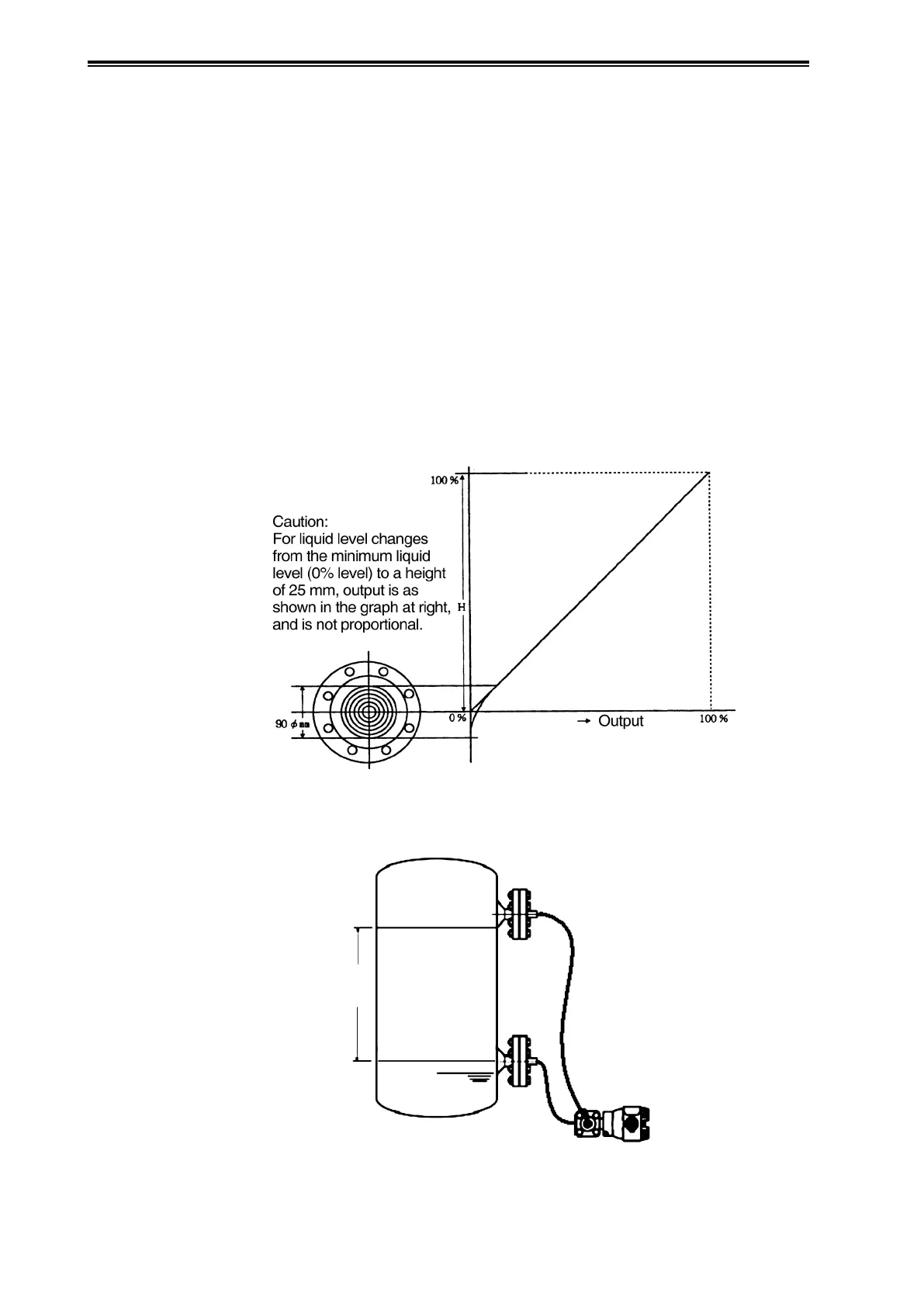

The zero position liquid level is taken to be the center of the seal diaphragm on the surface of the

process connection flange of the device (see Figures 3-6 and 3-7). As a result, the measurement

range H extends from the center of the transmitter flange to the height of the usage range. However,

when performing the zero point check, lower the liquid level to a point below the bottom of the

seal diaphragm. The device must be in a state in which head pressure is not being applied by the

process fluid. That is, check the zero point after putting the diaphragms on the high pressure side

and the low pressure side into an equalized pressure state in the tank. For information regarding

the method of checking, see the operation manual for the communicator.

Figure 3-6. Minimum Liquid Level Characteristics

100% Level

0% Level

H

Zero Point

Check Level

Figure 3-7. Zero Position Determination

Loading...

Loading...