2-37

Chapter 2 Installation of this Device

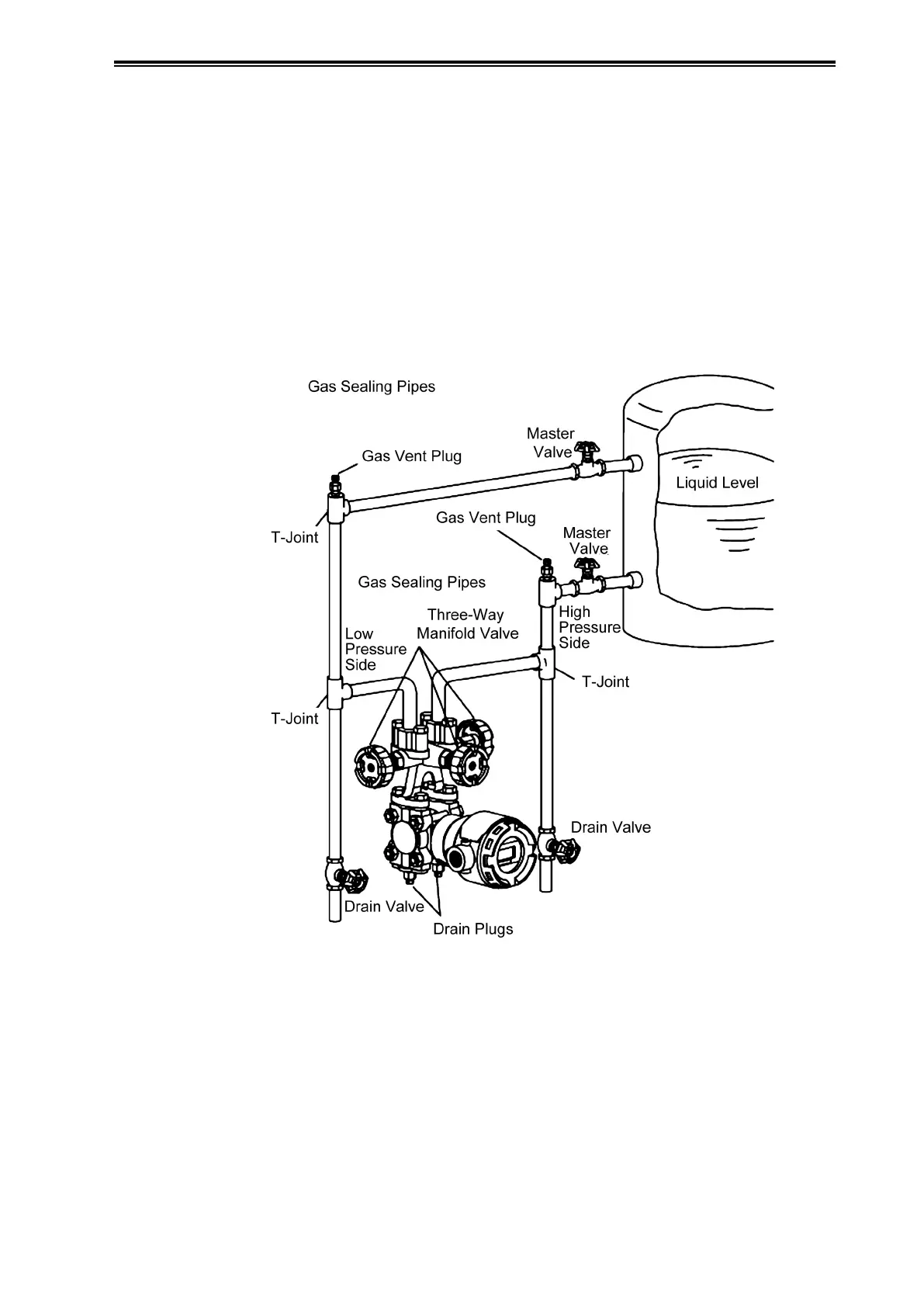

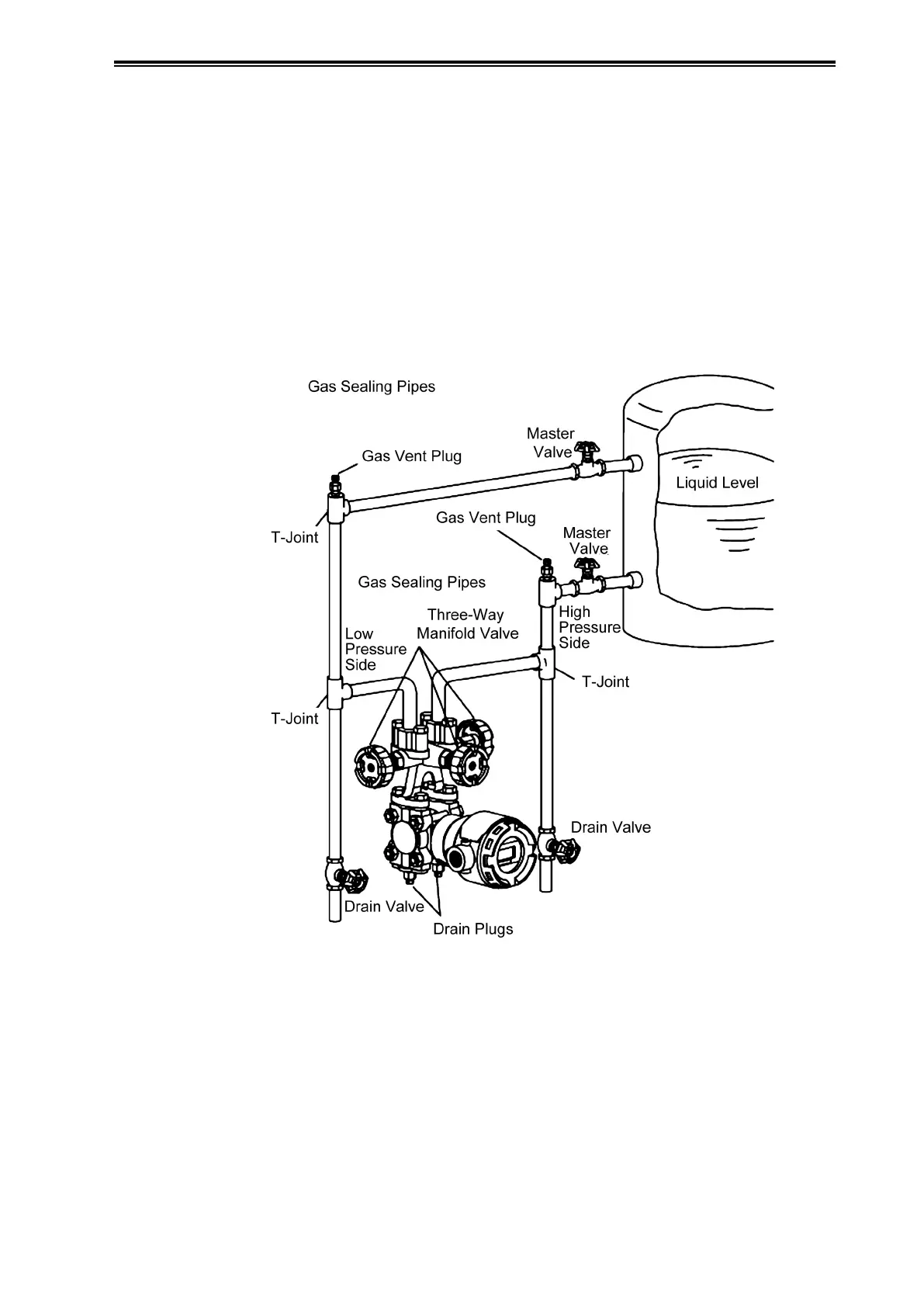

(3) Sealed Tank Piping

(i) Dry leg recommended piping example

A typical sealed tank dry leg liquid level piping example is illustrated below.

Be sure to implement the following items.

• Connect the high pressure side of the device to the lower portion of the tank, and connect the

low pressure side to the tank's gas seal pipe.

• Install the device in a location that is lower than the minimum level of the liquid to be measured.

• After doing the piping work, confirm that there are no pressure leaks in the connecting pipes,

the three-way manifold valve, the transmitter, etc.

• For the purpose of connecting pipe maintenance, use T-joints to attach drain valves.

Figure 2-42. Liquid Level Measurement (Sealed Tank, Dry Leg) Piping Example

Loading...

Loading...