3-20

Chapter 3 Starting and Stopping this Device

(2) Starting Operation

(i) Applying process pressure

In the following procedure, valves are operated to apply the differential pressure of the process

to this device, and then the measured values are checked using the communicator.

Procedure

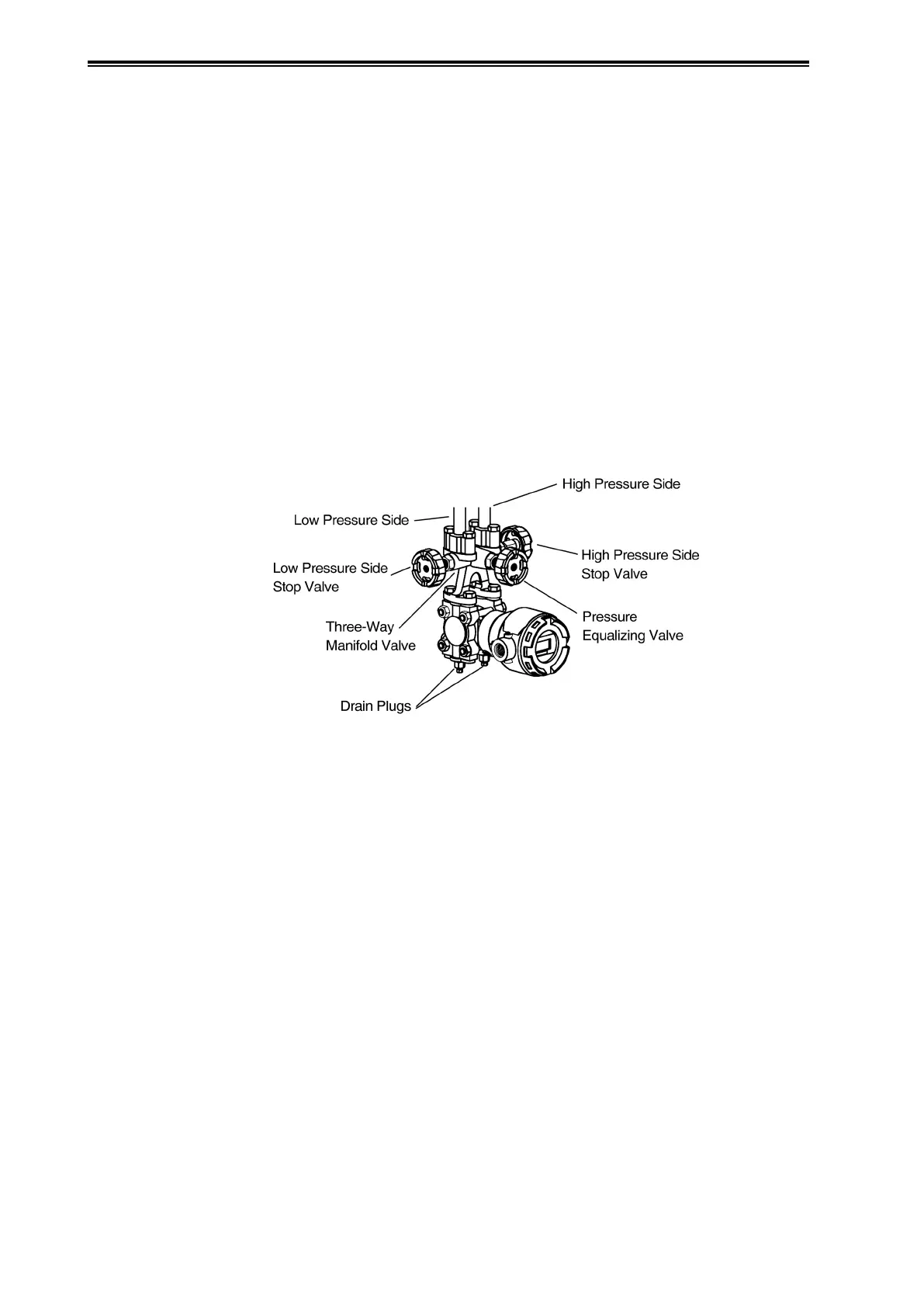

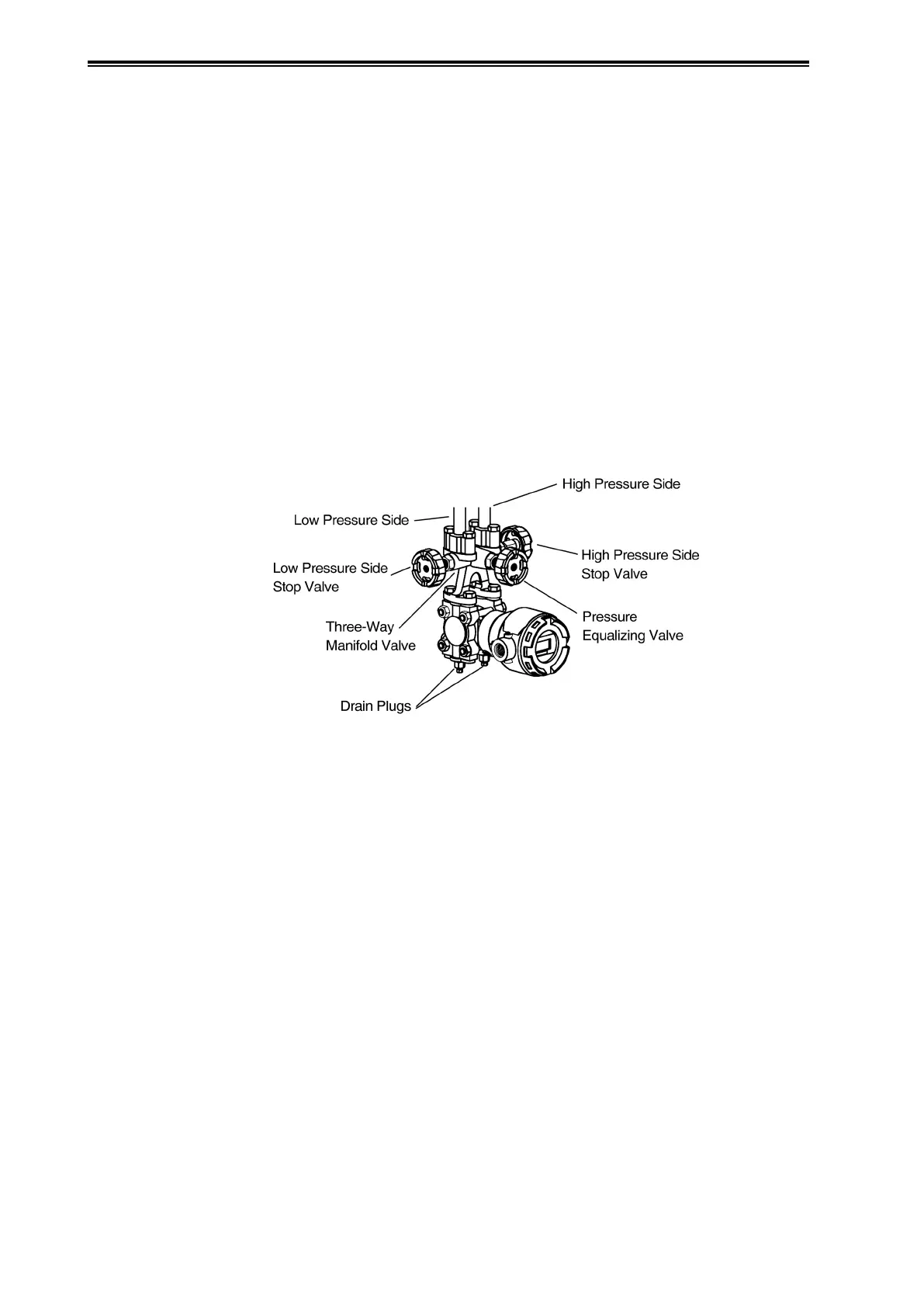

(1) Check that the valves of the three-way manifold valve are in the following state.

(1) High pressure side stop valve: fully closed

(2) Low pressure side stop valve: fully closed

(3) Equalizer valve: fully closed

(2) Fill the liquid seal pipes with sealing liquid.

(3) Introduce process pressure.

(1) Gradually open the high pressure side stop valve.

(2) Gradually open the low pressure side stop valve.

(ii) Zero point adjustment during measurement

When performing zero point adjustment during operation, see section 3-9.

(iii) Checking measured values

• Using the communicator, check the measured values.

• After checking , disconnect the communication cable, attach the device's case cover, and switch

the process to normal operation.

• If the analog signal output, the displayed values, etc., do not match the process conditions, recheck

the setting range and the like. If this does not solve the problem, carry out the troubleshooting in

Chapter 4, or contact us.

• If the measurement output and display do not stabilize, refer to Chapter 4 and adjust the damping

time constant.

(iv) Cautions following confirmation of readings

After checking the measured values, confirm that the device's case cover is securely closed. If it is

not securely closed, rainwater and the like can enter the device and cause damage to the terminals,

electronics modules, etc., located inside.

Loading...

Loading...