IS-28/28s

Baader Ísland ehf, Hafnarbraut 25, Kopavogur, IcelandTel: +354 520 6900 Fax: +354 520 6911

lager@baader.is / www.baader.is

29

INSTALLATION OF THE MACHINE

Before installing the machine it is mandatory for trained professionals to check all the

wiring to and from the parts for the raw material, processed products and waste, as

well as the connectors to other machines and the installation of the necessary input

wiring. Especially bear in mind the lighting and noise protection.

The operators and maintenance personnel must have ready access to the machine

from all the sides after the installation.

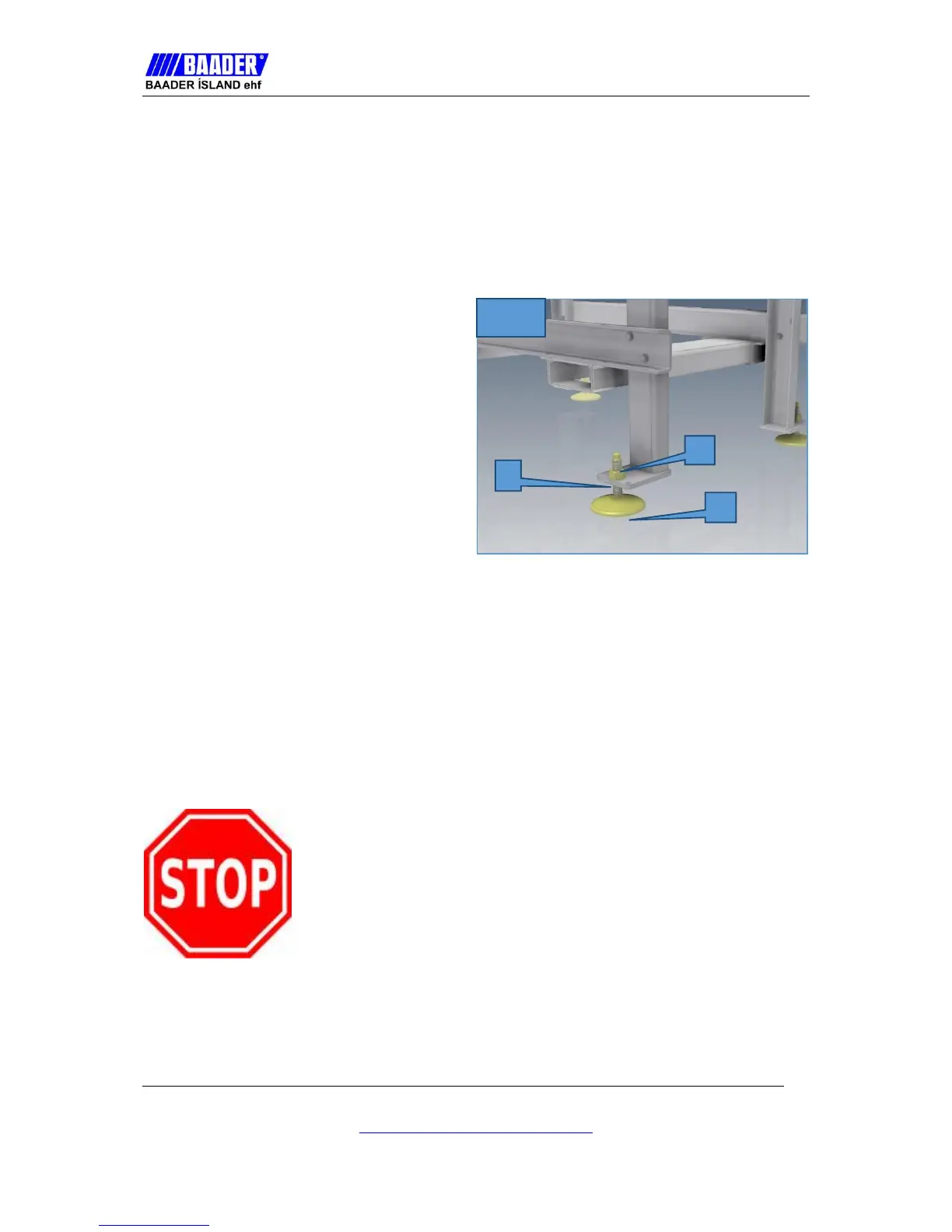

The machine installed on adjustable

spindles

Tools and materials

- 17 mm spanner

- 4 pieces of adjustable spindles

- 4 pieces of 100 mm footings

- 4 pieces of 24 mm nuts

Procedure

1. Move the machine to the

installation area (see

‘Transportation’)

2. Place adjustable spindles in all 4 footings of the machine (fig. 26, pos. 1)

3. Place a footing under each adjustable spindle (fig. 26, pos. 2)

4. Place the machine down until the adjustable spindles are on the footings.

5. Adjust the machine until it is positioned correctly

6. Place nuts on the adjustable spindles and tighten them (fig. 26, pos. 3)

Finishing

- Remove all the accessory equipment used in transportation, if applicable.

- Undo fastenings holding the flip-up protective parts firmly in place

- Fasten the platforms and install the footboard

WARNING!

Risk of machine falling down/worker falling over!

If the machine is elevated, its centre of gravity changes

accordingly. Take measures to prevent the machine from

falling down, especially if the platform is fixed to the

machine.

- Bolt the machine to the floor

- Install a handrail for the worker to prevent the

risk of falling.

Loading...

Loading...