Method Action Result

Push Button

Press and hold the TEACH button for more than 2 seconds.

Light Operate:

and

flash on the display. The DYN, FGS,

and BGS indicators flash.

Dark Operate:

and

flash on the display. The DYN, FGS,

and BGS indicators flash.

Remote Input

No action required. N/A

3. Teach the sensor.

Method Action Result

Push Button

Press the TEACH button.

The switching threshold flashes rapidly

and the sensor returns to Run mode.

Remote Input

Single-pulse the remote input.

Table 7: Expected TEACH Behavior for Dual (Intensity + Distance) Mode

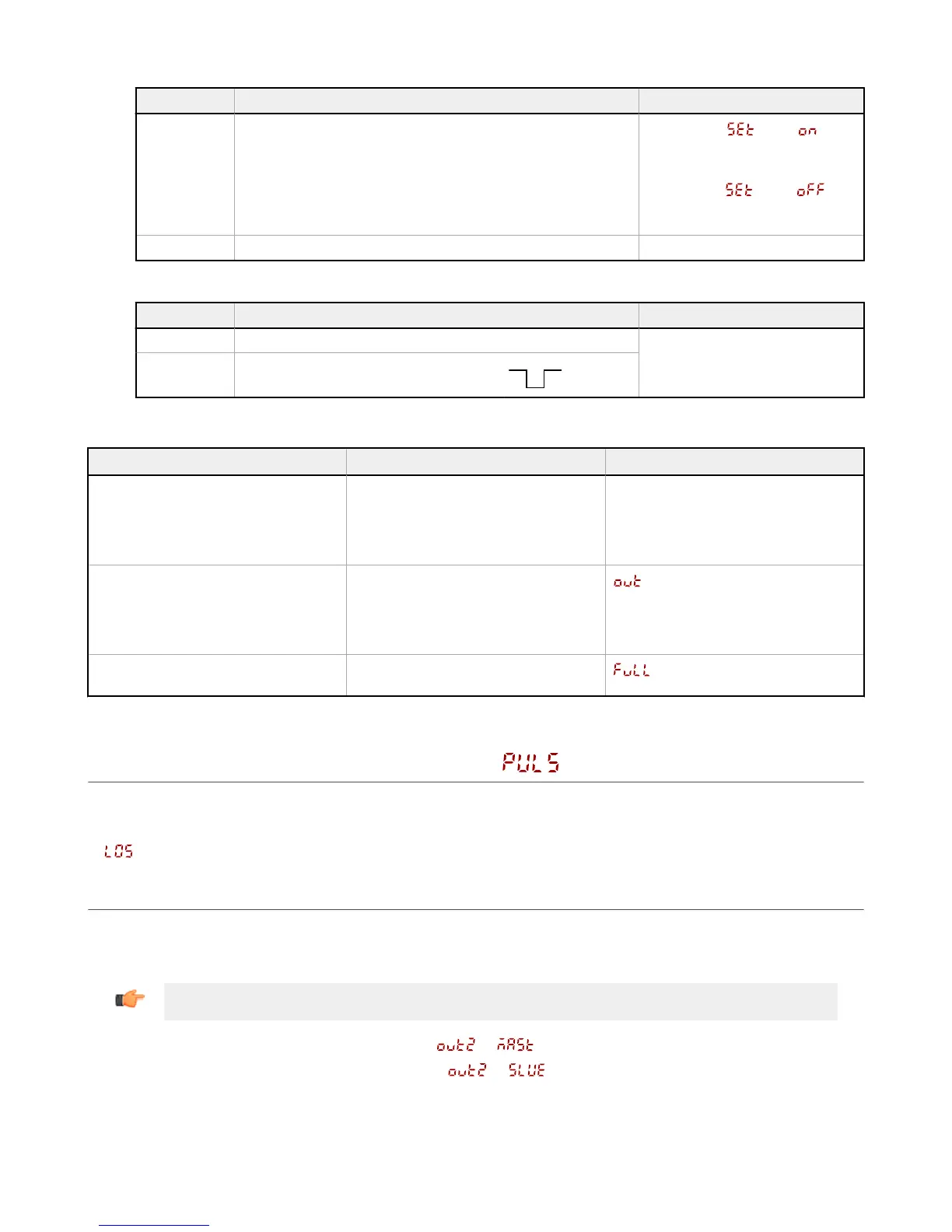

Condition TEACH Result Display

One valid reference surface is taught

within sensing range

Sets a dual (intensity + distance) window

centered around the taught reference

surface. The ± window size is the

previously used switching threshold, or

75% by default.

The switching threshold flashes on the

display.

One reference surface is taught outside

the sensing range

Sets a dual (intensity + distance) window

centered around the taught reference

surface that is outside the sensing range.

The sensing conditions may not be as

reliable.

flashes on the display.

One invalid TEACH Point No reference surface is taught, the output

will change when any object is detected.

flashes on the display.

3.7 Pulse Frequency Modulation (PFM) Output

The Q4X can generate pulses whose frequency are proportional to the sensor's measured distance, thereby providing a method for

representing an analog signal with only a discrete counter. The sensing range of the sensor is scaled from 100 to 600 Hz (100 Hz

equals the near range limit of the sensor, 600 Hz equals the far sensing range limit). An output of 50 Hz represents a Loss of Signal

(

) condition where there is no target or the target is out of the sensor's range.

3.8 Sync Master/Slave

Two Q4X sensors may be used together in a single sensing application. To eliminate crosstalk between the two sensors, configure

one sensor to be the master and one to be the slave. In this mode, the sensors alternate taking measurements and the response

speed doubles.

Important: The master sensor and the slave sensor must be programmed for the same Response Speed and Gain and

Sensitivity settings. The master sensor and slave sensor must share a common power source.

1. Configure

the first sensor as the master; navigate:

> .

2. Configure

the second sensor as the slave; navigate:

> .

3.

Connect the gray (input) wires of the two sensors together.

Q4X Stainless Steel Laser Sensor with Dual Discrete Outputs and IO-Link

28 www.bannerengineering.com - Tel: 763.544.3164

Loading...

Loading...