6 Additional Information

6.1 Dual (Intensity + Distance) Mode

In background suppression (DYN, 1-pt, 2-pt) and foreground suppression (FGS) TEACH modes, the Q4X sensor compares

changes in the measured distance between the sensor and target to control the output state. Dual TEACH mode, dual intensity +

distance window, expands the applications the Q4X can solve by combining distance-based detection with light intensity

thresholds. In dual TEACH mode, the user teaches the Q4X a fixed reference surface, and the sensor compares intensity and

distance readings against the reference surface it was taught. After teaching the reference target, the displayed value is calibrated

to 100P, or a 100% match. When an object enters the sensor’s

field of view, the degree of consistency with the reference surface

becomes lower and causes a change in sensor output.

In dual mode, you can detect when the target is present at the right distance and when it returns the right amount of light. This is

useful in error-proofing applications where you need to know not only that the part is present (distance), but also that it is the

correct part (intensity).

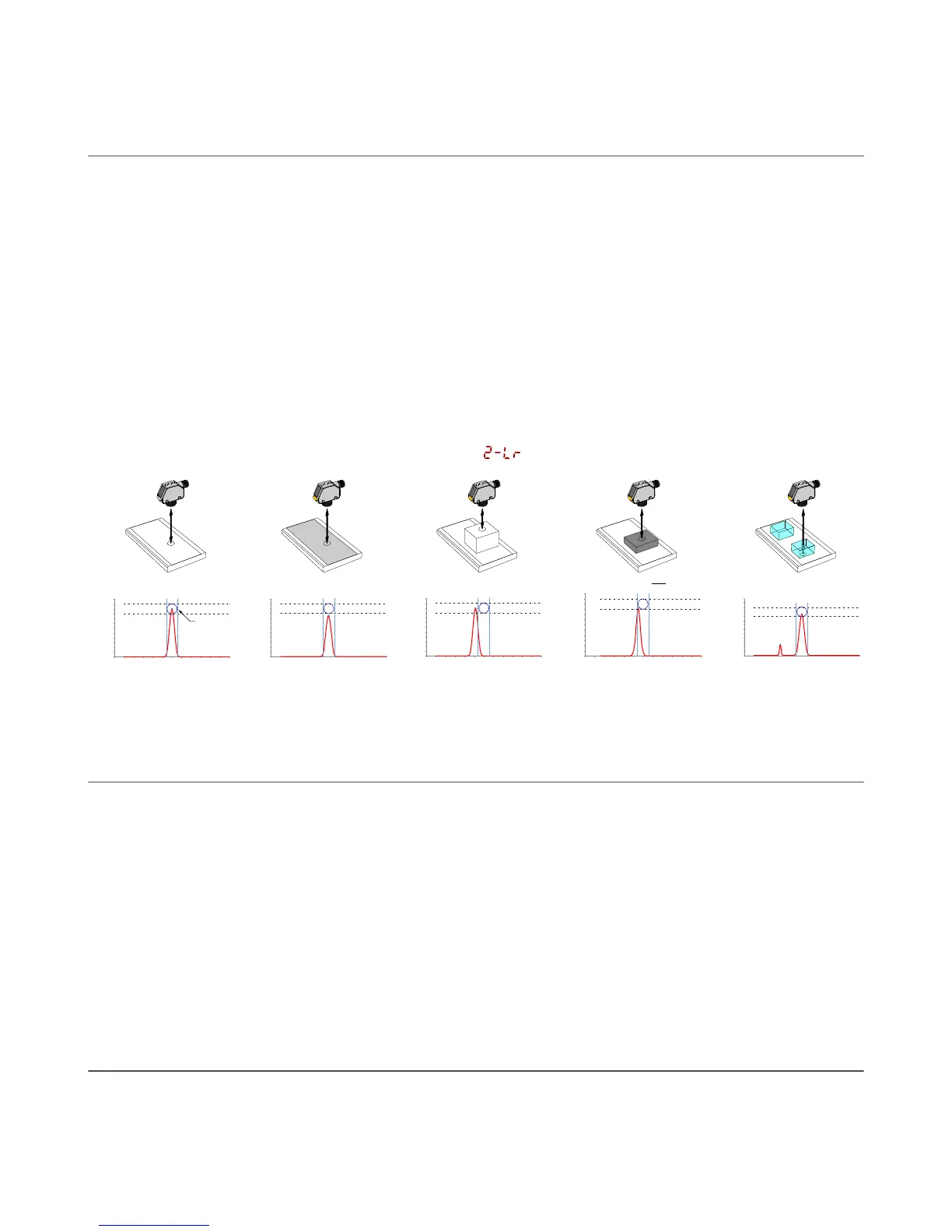

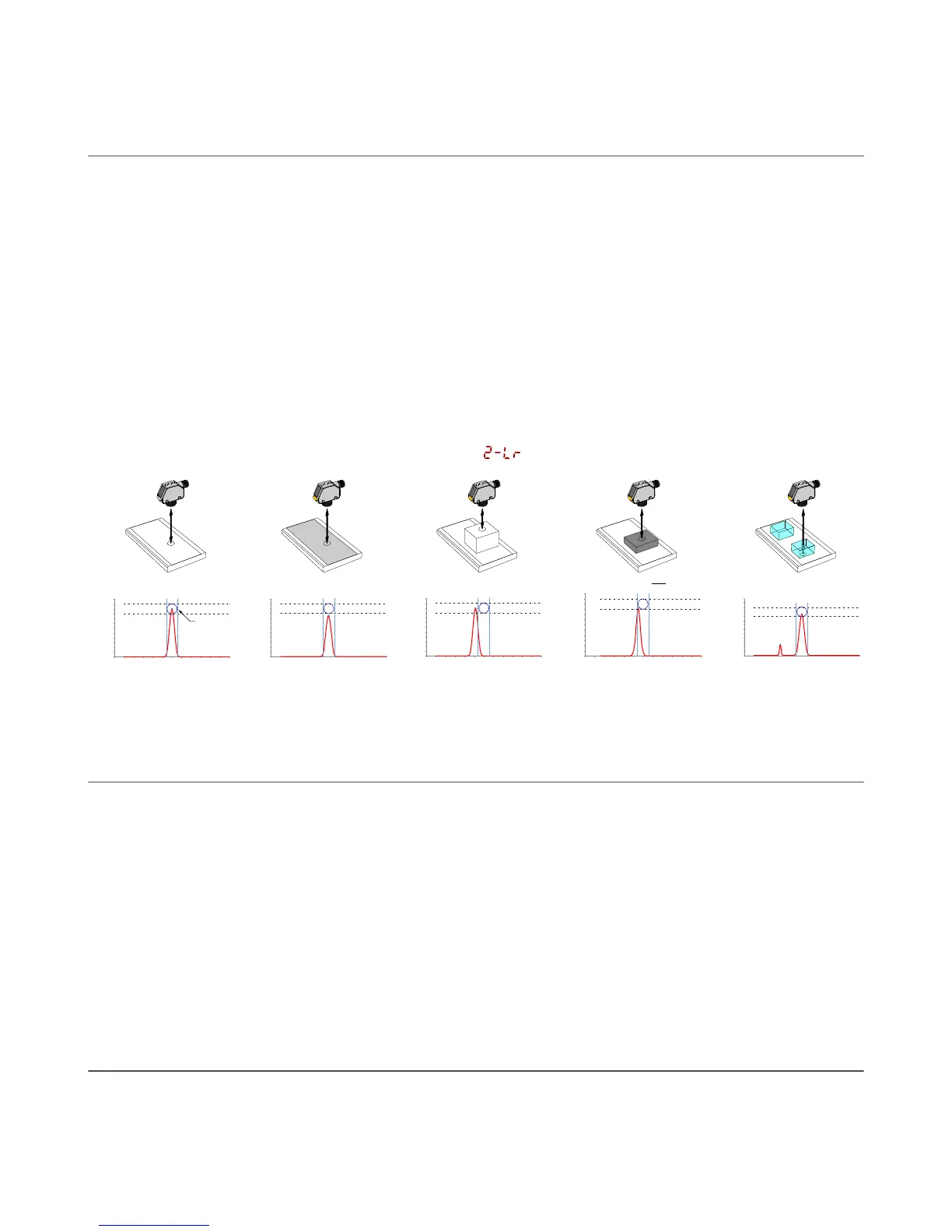

In dual mode, the Q4X requires a reference surface (far left). Once taught, the distance and intensity of the reference surface are

recorded and used as a baseline. A user adjustable switching threshold is set, and changes in distance and/or intensity outside the

switching threshold creates a sensor output change. The example above uses a 90% (90P) match condition with a 10% change in

intensity and/or distance from the reference surface required to change the output state. The default-switching threshold is a 75%

match to the reference condition (75P); this sets the threshold 25% from the distance and intensity of the reference surface. A

transparent object can be detected either by a change in intensity, distance, or by a double peak reflection (far right). When a

double peak

reflection is detected, the display alternates between

and the percent match.

Reference Condition

0

10

20

30

40

50

60

70

80

90

100

110

120

0 25 50 75 100 125 150 175 200 225 250 275 300

10% Switching

Threshold

100% matched distance + Intensity after Dual teach

Intensity

(% of taught reference)

Distance (mm)

Change in Intensity

0

10

20

30

40

50

60

70

80

90

100

110

120

0 25 50 75 100 125 150 175 200 225 250 275 300

Output switches with intensity change

Intensity

(% of taught reference)

Distance (mm)

Change in Distance

0

10

20

30

40

50

60

70

80

90

100

110

120

0 25 50 75 100 125 150 175 200 225 250 275 300

Output switches with distance change

Intensity

(% of taught reference)

Distance (mm)

Change in Distance and Intensity

0

10

20

30

40

50

60

70

80

90

100

110

120

0 25 50 75 100 125 150 175 200 225 250 275 300

Output switches with intensity and distance change

Intensity

(% of taught reference)

Distance (mm)

Reduced Intensity and/or Second Peak

0

10

20

30

40

50

60

70

80

90

100

110

120

0 25 50 75 100 125 150 175 200 225 250 275 300

Output switches with intensity and/or second peak (Clear Object Detection)

Intensity

(% of taught reference)

Distance (mm)

The Q4X sensor can be taught non-ideal reference surfaces, such as surfaces outside of the sensor’s range, very dark surfaces, or

even empty space. These situations may enable applications requiring a long range detection but are subject to typical diffuse

mode detection challenges.

6.2 Dual Mode Reference Surface Considerations

Optimize reliable detection by applying these principals when selecting your reference surface, positioning your sensor relative to

the reference surface, and presenting your target. The robust detection capabilities of the Q4X allows successful detection even

under non-ideal conditions in many cases. Typical reference surfaces are metal machine frames, conveyor side rails, or mounted

plastic targets. Contact Banner Engineering if you require assistance setting up a stable reference surface in your application.

1.

Select a reference surface with these characteristics where possible:

• Matte or diffuse surface finish

• Fixed surface with no vibration

•

Dry surface with no build-up of oil, water, or dust

2. Position the reference surface between 50 mm and the maximum sensing range for threaded barrel models or between 60

mm and the maximum sensing range for flush mount models.

3.

Position the target to be detected as close to the sensor as possible, and as far away from the reference surface as

possible.

4. Angle the sensing beam relative to the target and relative to the reference surface 10 degrees or more.

6.3 Dual Mode Considerations for Clear and Transparent Object Detection

The Q4X is able to detect the very small changes caused by transparent and clear objects. A transparent object can be detected

either by a change in intensity, distance, or by a double-peak reflection.

Q4X Stainless Steel Laser Sensor with Dual Discrete Outputs and IO-Link

36 www.bannerengineering.com - Tel: 763.544.3164

Loading...

Loading...