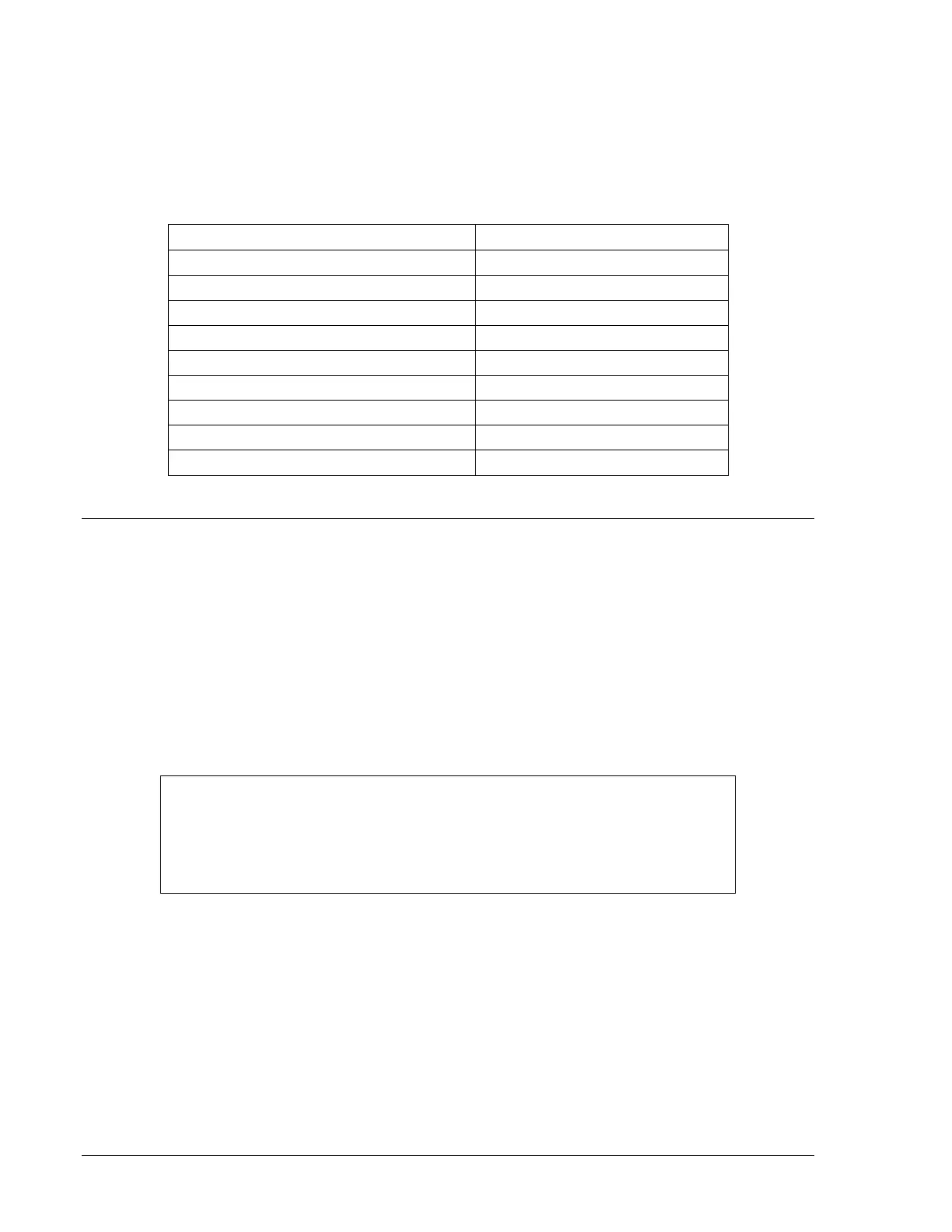

Front Panel Adjustable Parameters

Most DGC-500 settings can be viewed at the front panel display. The settings that can be adjusted at the

front panel are listed in Table 3-4. With the exception of the time and date, all of the listed settings are

protected by the front-panel key code.

Table 3-4. Front Panel Adjustable Settings

Parameter Setting Range, Increment

Sensor Failure Alarm Time Delay 1 to 30 s, 1 s

Metric Conversion On or Off

Low Fuel Pre-Alarm Level 10 to 100%, 1%

Low Fuel Alarm Level 2 to 50%, 1%

Pre-Crank Contact After Cranking Open or Closed

Cool-Down Time 0 to 60 m, 1 m

Pre-Crank Time Delay 0 to 30 s, 1 s

Time N/A

Date N/A

ENGINE CONTROL UNIT (ECU) SUPPORT

The following paragraphs describe the support provided by the DGC-500 for operation with an engine

control unit (ECU).

Enabling ECU Support

To enable ECU support, the user must access the SYST menu in BESTCOMS and select Enable ECU

Support under the box entitled CANBus/J1939 Interface. After resending the settings, the DGC-500 will

ignore the analog inputs for coolant temperature, oil pressure and engine speed, and it will no longer

calculate engine run-time. Once the DGC-500 establishes communication with an ECU, the engine run-

time, coolant level, coolant temperature, oil pressure, and engine speed will be updated with the ECU

values.

ECU Constraints

An external source cannot always turn the engine off without removing power from the ECU. Removing

power from the ECU is the only way to remove fuel from the engine and shut it down. Different ECU

manufacturers have their own rpm setpoints for reapplying fuel to an engine. For example, if the ECU is

powered up and the engine is still spinning above 60 rpm, the ECU may automatically turn the fuel on.

Not being able to stop the engine without removing power from the ECU causes two problems. The first

problem is that the only way to stop the engine is to turn the ECU off and wait for the engine speed to

decrease below 60 rpm before reapplying ECU operating power. Otherwise, the engine will resume

running. The second problem is that while the ECU is off, you can no longer meter and update coolant

level, coolant temperature, oil pressure, and engine speed values, effectively disabling features like low

coolant temperature alarm/pre-alarm and crank control.

NOTE

With Enable ECU Support selected, there is a non-programmable Coolant Level

Sender Fail alarm that can annunciate when the engine is either off or running.

Coolant level is metered and displayed only when Enable ECU Support is

selected in BESTCOMS.

3-26 DGC-500 Functional Description 9355400990 Rev H

Loading...

Loading...