Important Preliminary Remarks

Infusomat® compact

plus

P 1.0 0 - 7

EN

For internal use, only

CHECK AFTER REPAIR The checks after repair depend on the service work performed. They

follow the Check after Repair Matrix. If several servicing activities

have been carried out, the total of all necessary tests (checks) has

to be performed.

If no Check after Repair Matrix is defined, perform the checks after

repair according to the TSC checklist as mentioned later in this

manual.

NOTES ON ESD Semiconductors can be destroyed by electrostatic discharge. Espe-

cially MOS components can be damaged by interference from elec-

trostatic fields, even without discharge via contact. This type of

damage is not immediately recognizable. Unit malfunctions can

even occur after a longer period of operation.

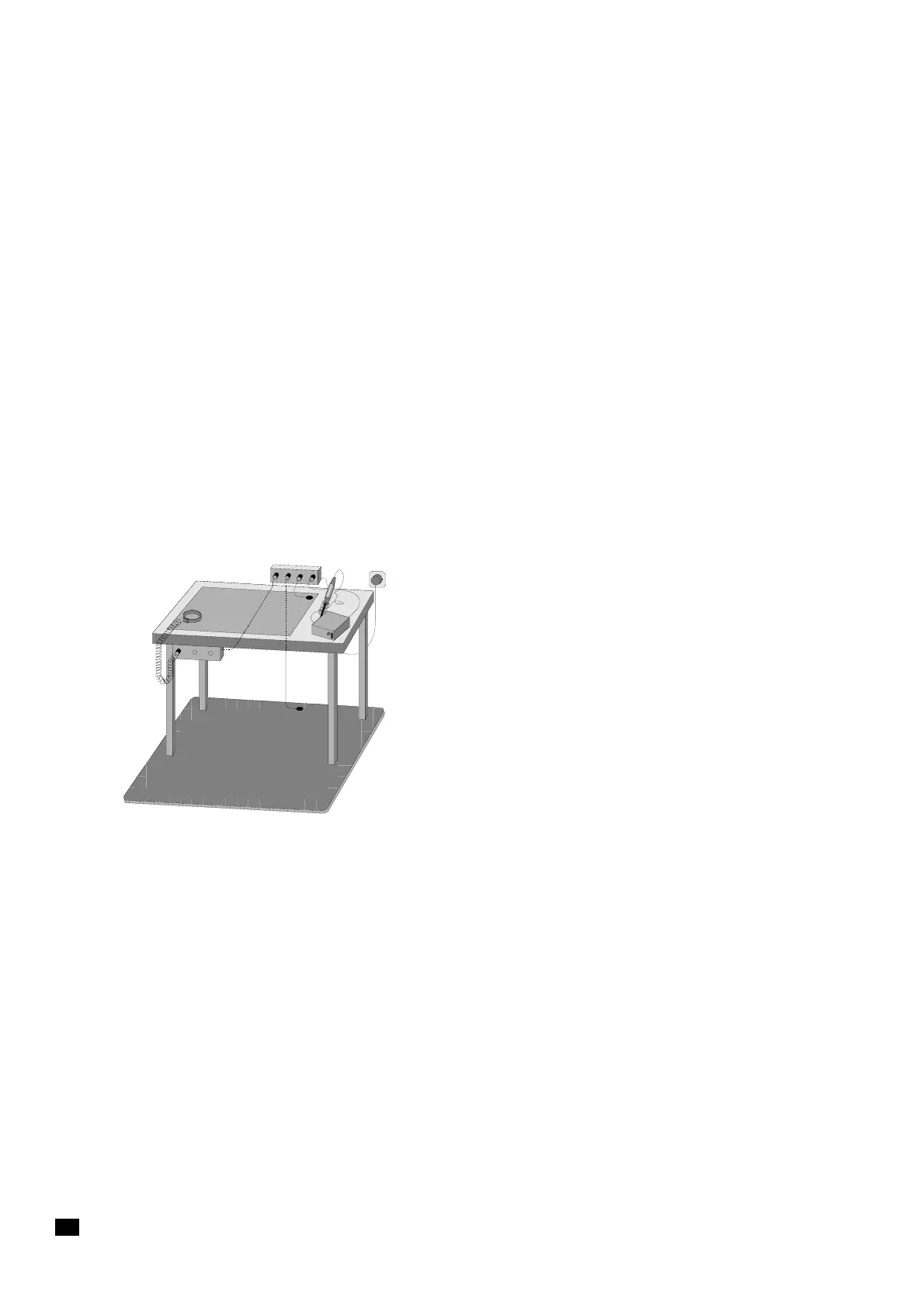

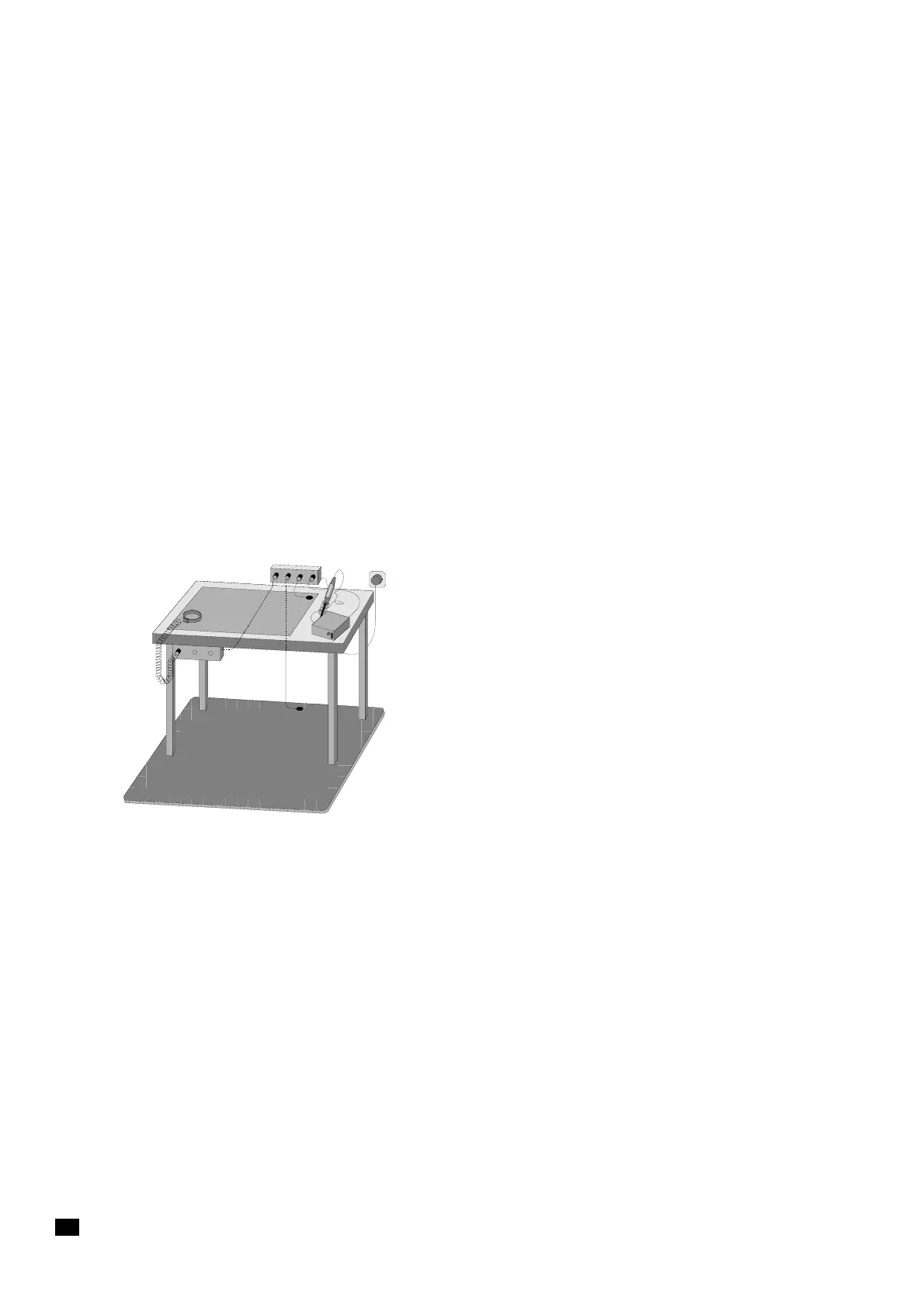

Each workstation must be equipped according to the recommen-

dations with the necessary static protective measures, if ESD com-

ponents or boards are handled (Fig. 0 - 1).

Each workstation must be equipped with a conductive table sur-

face. The conductive surface, the soldering iron or the soldering

stations must be grounded via protective resistors.

Chairs must be of antistatic design. The floor or floor mats should

be of electrically conductive material.

Personnel must wear conductive wristbands which are connected

to a central ground potential via protective resistors, e.g. the

ground contact of a wall outlet. Furthermore it is recommended

that personnel wear cotton clothing and electrically conductive

shoes to prevent electrostatic charge.

SPARE PARTS Only use original spare parts from B. Braun. Do not tamper with

them. Never integrate assembly groups into a device that have

been extracted from an other device.

Fig. 0 - 1 Example of a workstation with ESD protection equipment

Loading...

Loading...