BEUMER stretch hood® S

Trouble shooting

BA-6090103-EN

19.08.09

91

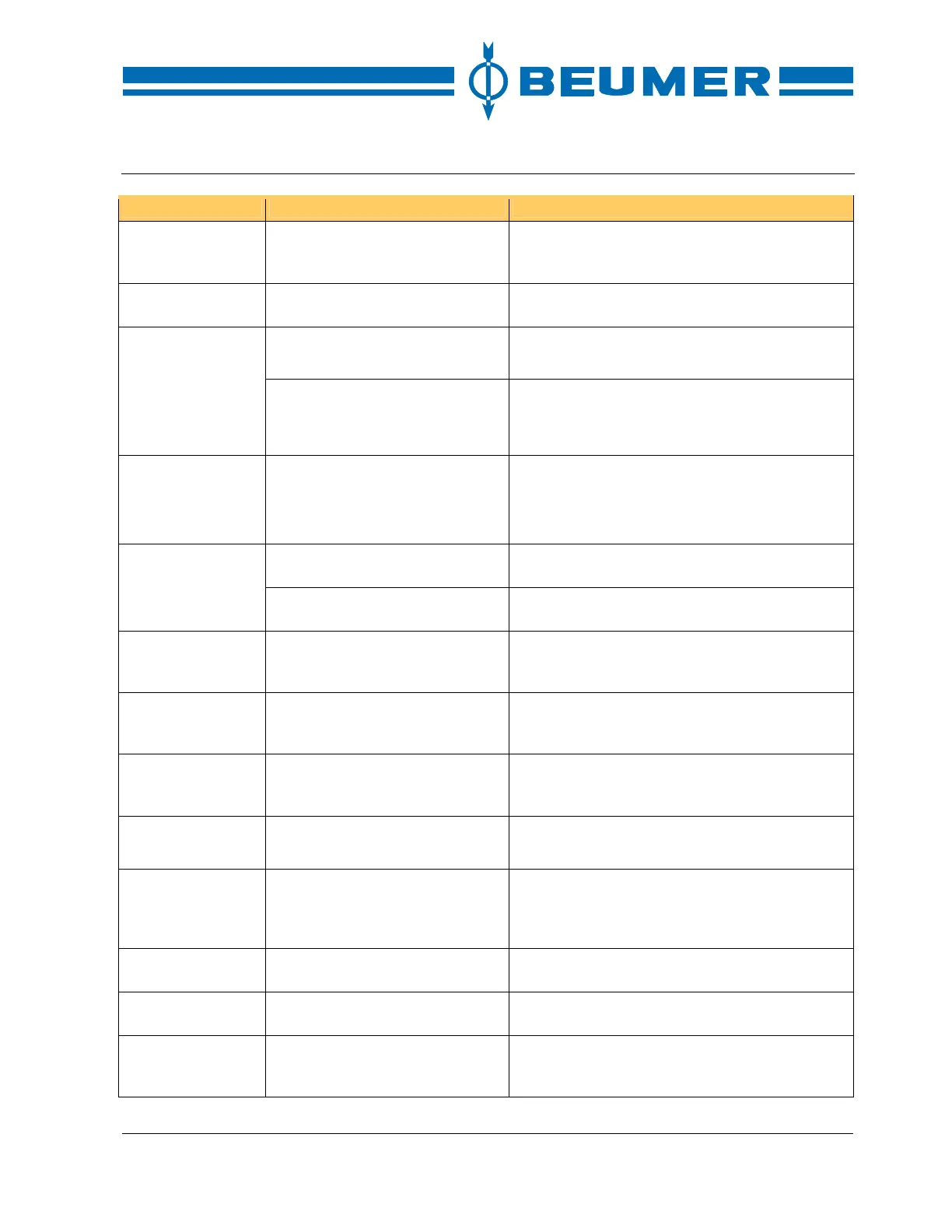

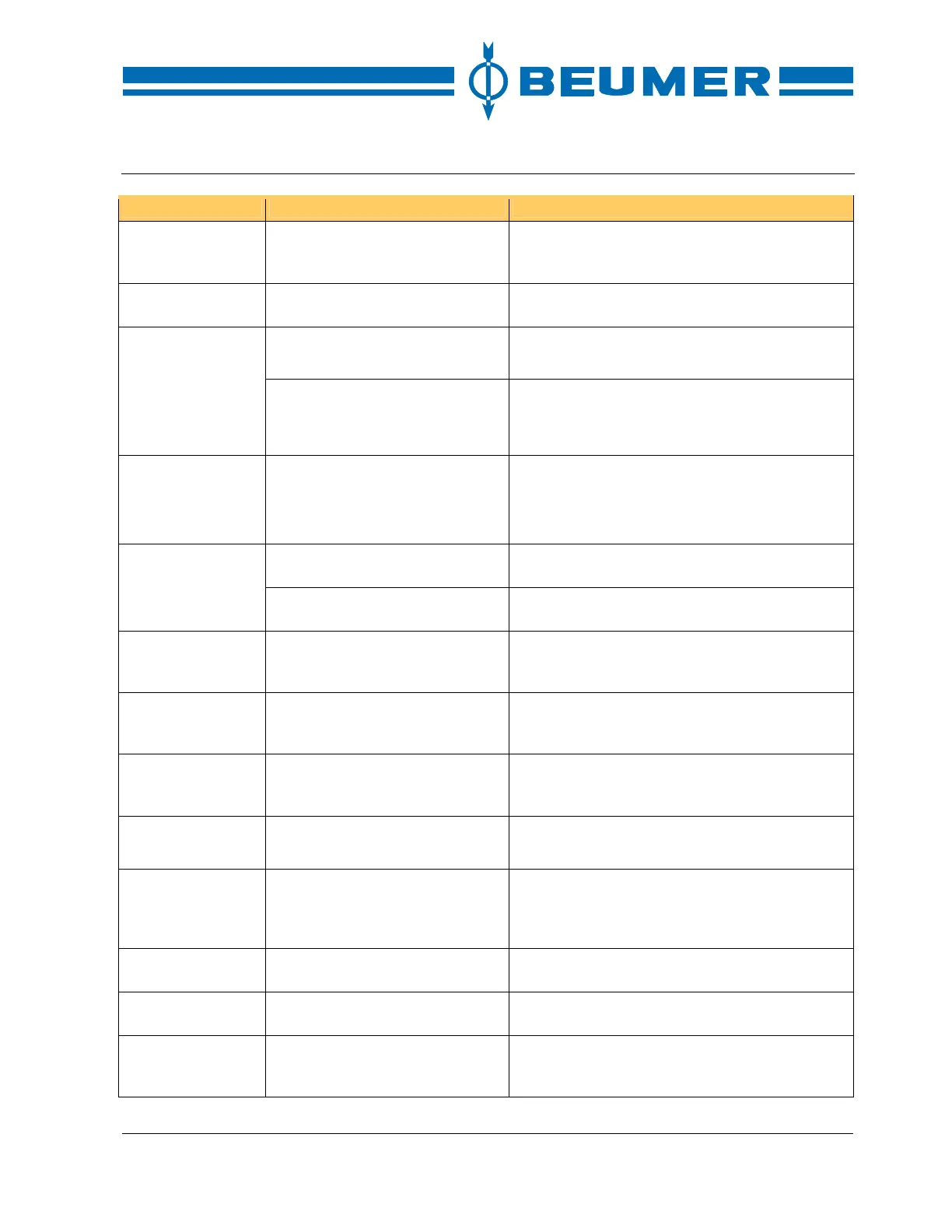

Problem Possible cause Trouble-shooting

The operation stop relay in the

control cabinet has been switched

off.

Press the "Reset operation stop" key.

Maintenance switch The maintenance switch has

been switched off.

Switch on the maintenance switch again.

The ray of the safety photocell

has been interrupted.

Activate the reset key on the evaluator.

Ensure that nobody is in the safety area.

The safety photocell

(SLS) has been

tripped.

The safety photocell is out of

function.

• Readjust the safety photocell.

• Check the wiring.

• Activate the reset key on the evaluator.

Muting error of the

safety photocell

The safety photocell was disabled

for more than 10 minutes.

• Take any foreign matters out of the safety

area.

• Check and adjust the disabling photocells

(see the Safety chapter).

One safety bolt of the stretch

frame has not moved back.

Check the pneumatic cylinder for sluggish

movement.

Safety bolt of the

stretch frame

The limit position of a safety bolt

has not been detected.

Check the proximity switches.

Control voltage 230

V not existing

The automatic circuit breaker for

the control voltage of 230 V has

failed.

Find out the cause of the overload and eliminate

it. Then switch on the automatic circuit breaker

again.

Control voltage 24

V not existing

The automatic circuit breaker for

the control voltage of 24 V has

failed.

Find out the cause of the overload and eliminate

it. Then switch on the automatic circuit breaker

again.

Compressed air

below 4 bar

The air pressure has fallen below

4 bar.

Check the air pressure and set the correct pres-

sure. Check the pressure switch and set it, if

required.

Communication

OP-AG has failed

The connection between control

and control terminal is interrupted.

• Check the wiring.

• Check the plug-in connectors.

Package not in

position

The package is not centrally be-

low the stretch hood.

Position the package centrally under the stretch

hood by hand. The photocells on the conveyor

used for checking the position of the pallet must

be occupied.

Film tends to fall

down

Film has moved back too far. Insert the film once again (see How to insert the

film).

Film has torn The film has torn during the

stretching process.

Start the "Starting position" function, remove the

torn film and repeat the stretching process.

There is still film on

the crimping bow

diffuse scan has still detected

film on the crimping bows before

lifting the stretch frame.

Remove the film from the crimping bows. Reset

the fault and start the machine/system once

again.

Loading...

Loading...