Maintenance

BEUMER stretch hood® S

96 BA-6090103-EN

19.08.09

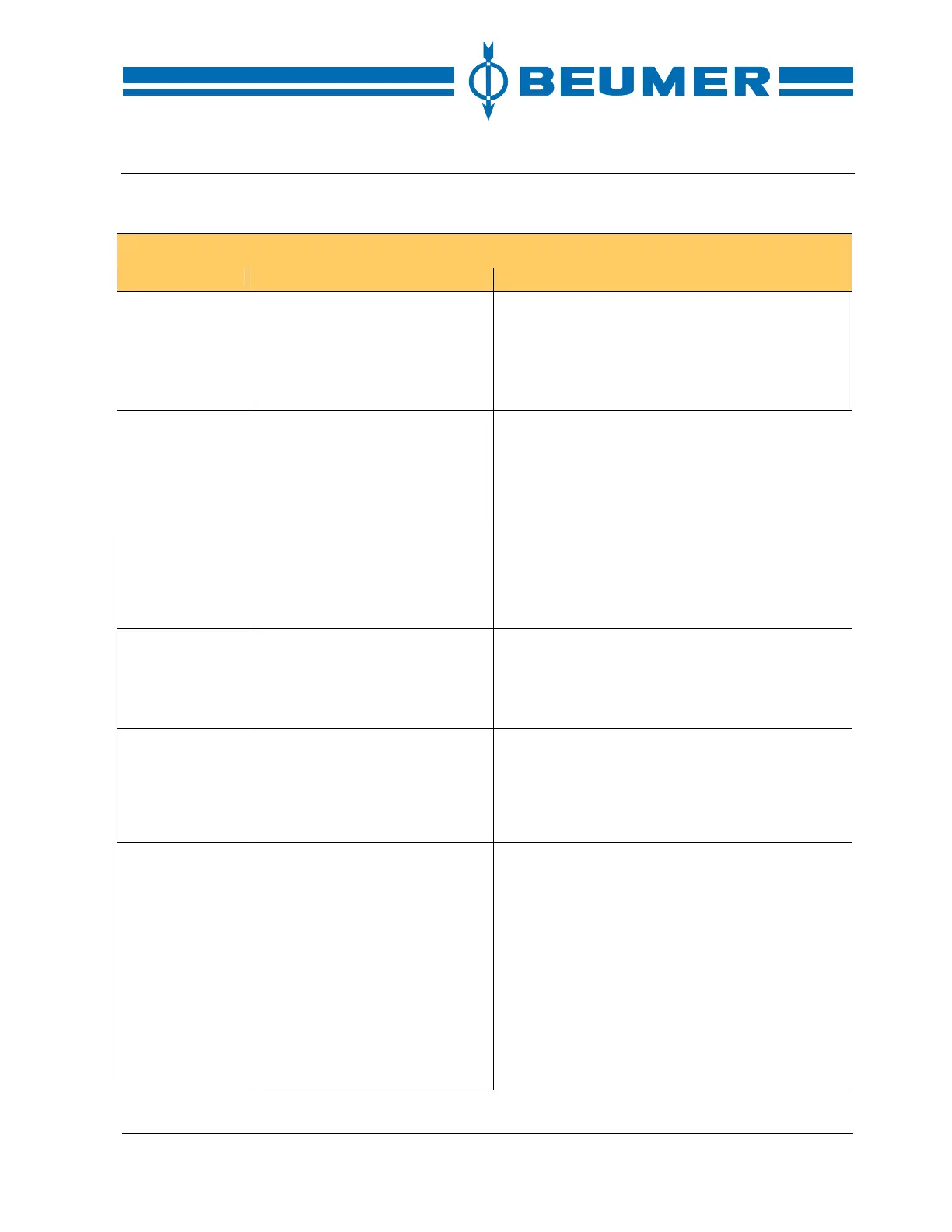

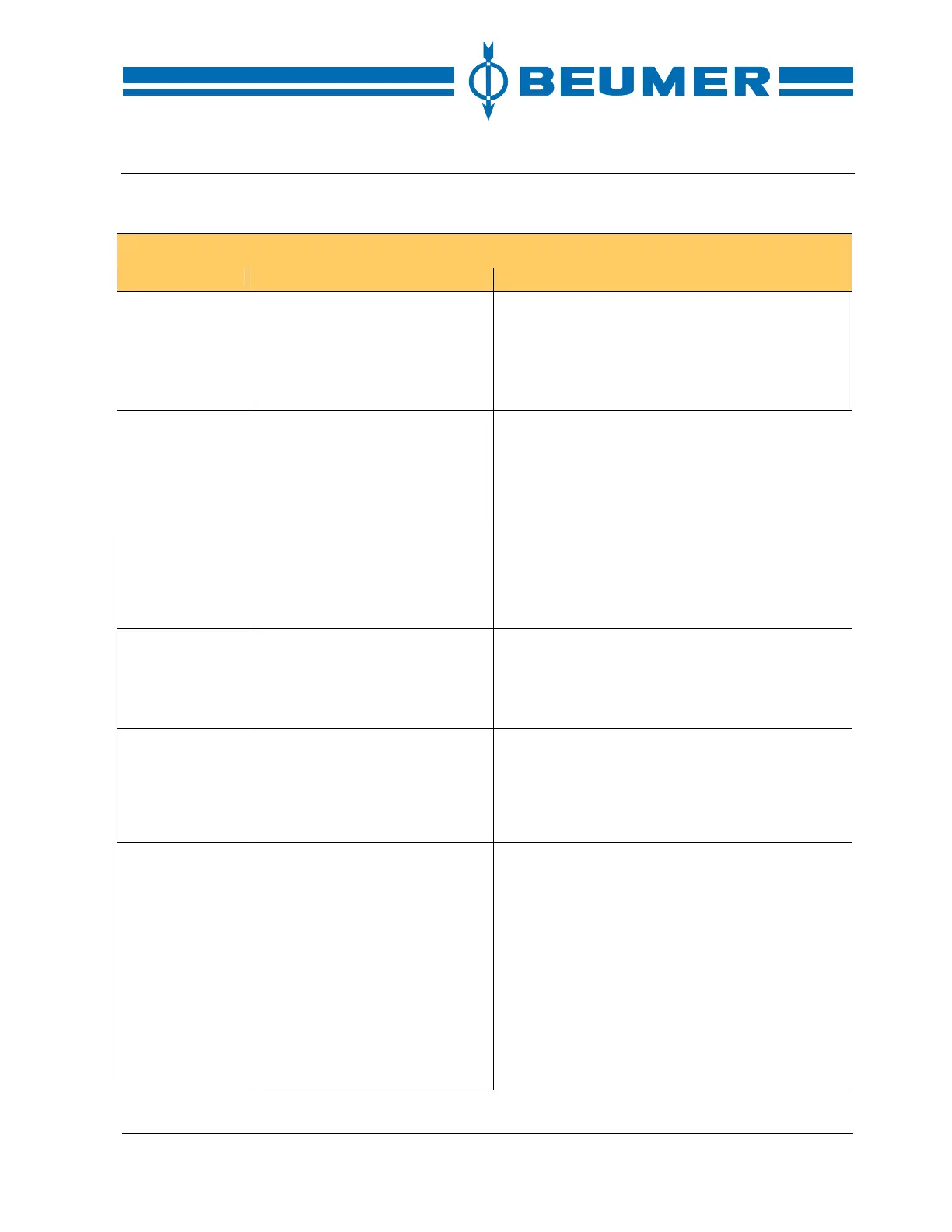

Inspection

Inspection list

Interval Subassembly Work / checks to be carried out

Annually Frames, steel structures and

machine parts

Visual check:

• Signs of corrosion

• Deformation of subassemblies

• Welding seams for cracks

• Repair the coat of paint, if required.

Every six months Pedestal bearing units and

flanged bearing units

Bearing units without grease nipple are provided

with permanent lubrication.

• Check the fastening.

• Unusual noise during operation? Replace the

complete bearing unit.

Every six months Connecting elements Check:

• Check the nut locks for completeness and

function.

• Check the dynamically loaded screws for inter-

ference fit.

Quarterly Idlers

• Do all idlers rotate?

Replace the idlers which do not rotate.

• Have the idlers been correctly aligned and

fastened?

Quarterly Crimping and stretching unit

• Can the rollers on the crimping bow be turned

easily?

• Are the touch-down switches deformed?

• Can wear and tear be detected on the crimping

and stretching unit?

Monthly Sealing bar Visual check:

• Is the film cut evenly? If not, the knife must be

replaced.

• Does the Teflon fabric belt show burnt spots,

caking or holes? If so, the Teflon fabric belt

must be replaced.

• Is the sealing seam regular? An irregular seal-

ing seam or points which are not sealed point

to a defective strip heater.

The Teflon fabric belt, the strip heater and

the rubber strip must always be replaced

together.

Loading...

Loading...