BEUMER stretch hood® S

Maintenance

BA-6090103-EN

19.08.09

97

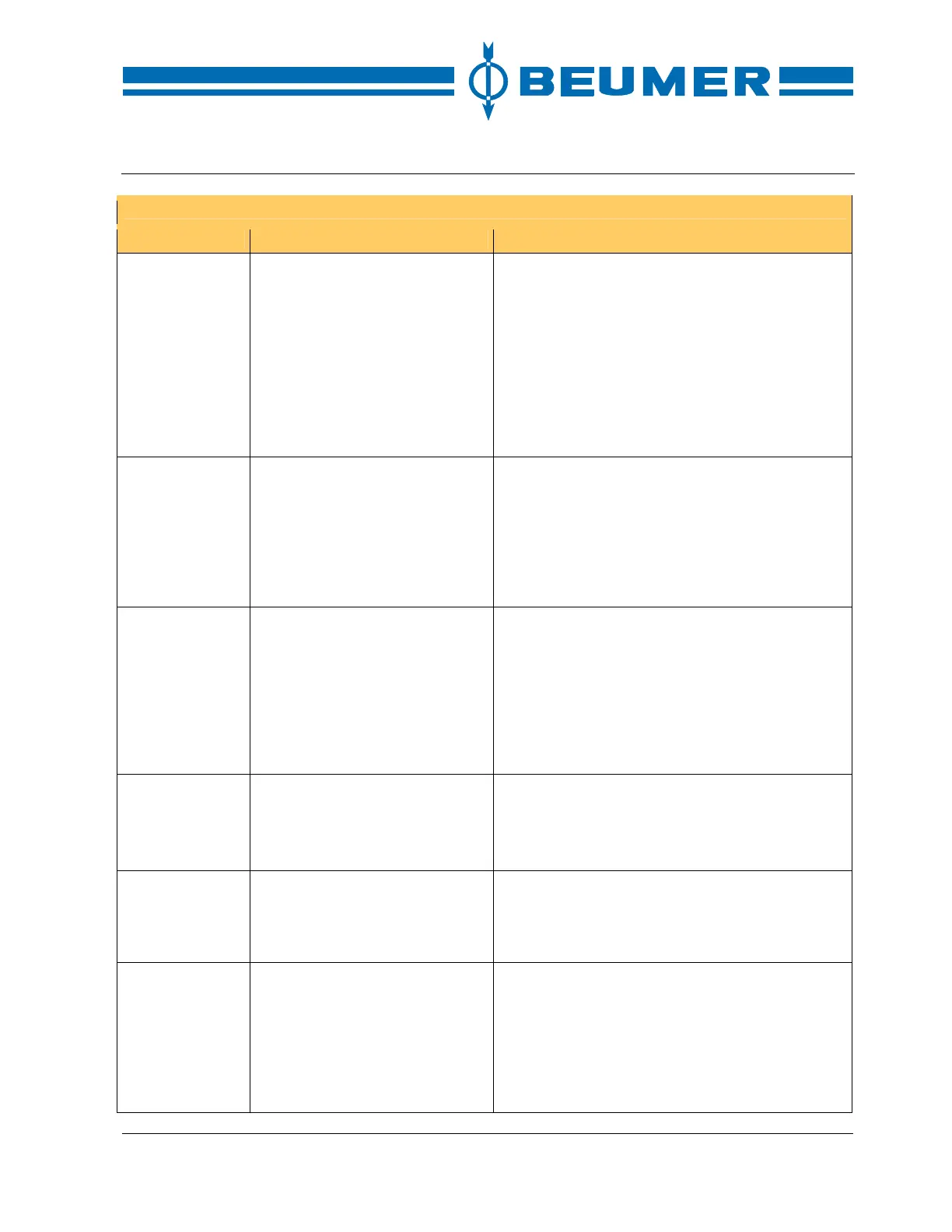

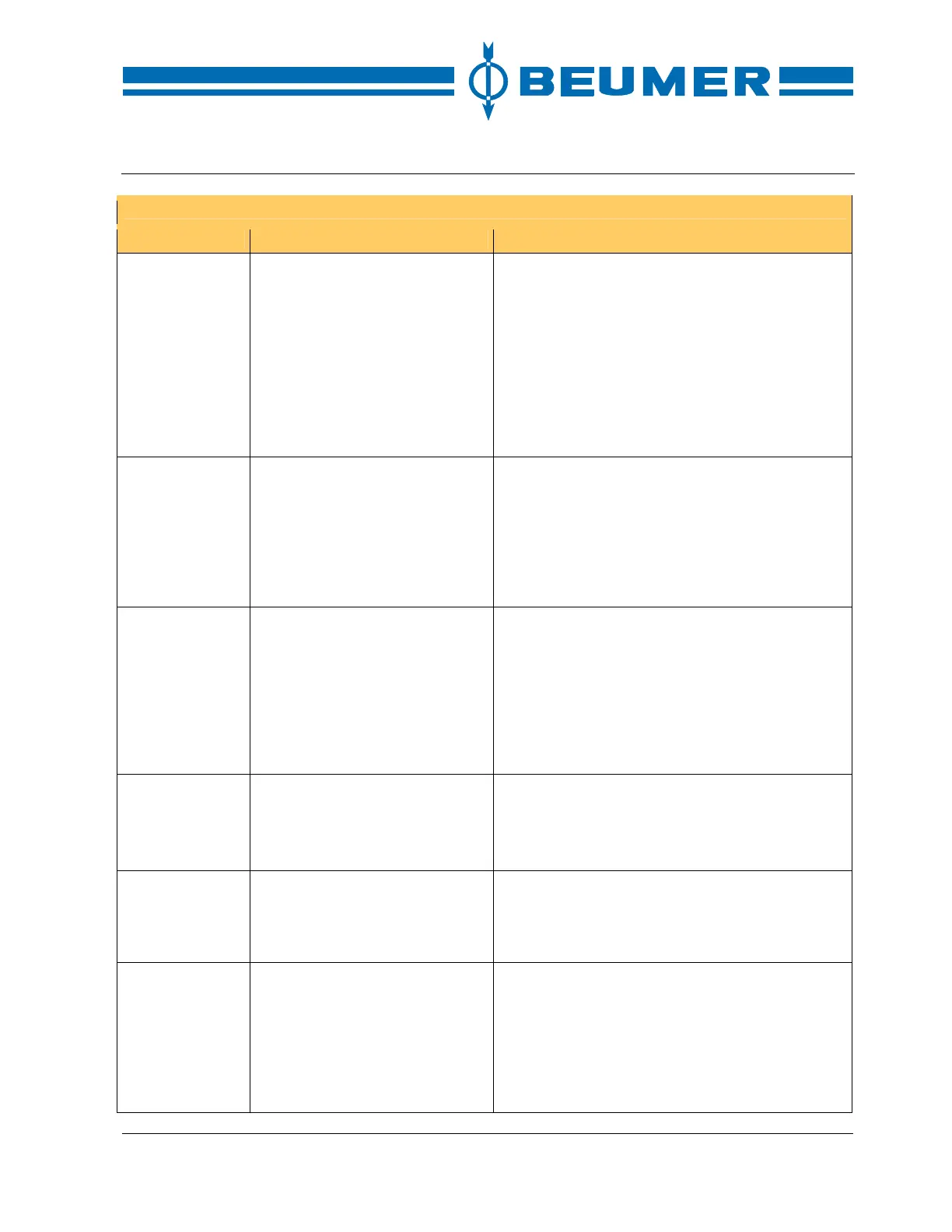

Inspection list

Interval Subassembly Work / checks to be carried out

Monthly Pneumatic components Air service unit:

• Are the connections tight?

• Has the correct operating pressure been set?

• Check the condensate level and drain off the

condensate.

Cylinder:

• Are the connections tight?

• Are the proximity switches correctly fastened

and functional?

Monthly Toothed gears and rack The following parameters are to be checked:

• Fastening

• Damage to the toothed gears

• Ensure that the lubricating film on the teeth is

sufficient. Use grease for open gear drives ac-

cording to OGPF 0 N-20, i.e. adhesive lubri-

cants without bitumen of the NLGL class 0.

Monthly Photocells The following parameters are to be checked:

• Have the photocell supports been correctly

fastened? Retighten loose screw and bolt con-

nections.

• Do the photocells function? Replace defective

photocells.

• Are the photocells dirty? Eliminate any dirt on

the photocells.

Monthly Proximity switch The following parameters are to be checked:

• Operating distance

• Function

• Fastening

At the beginning

of the shift

Emergency stop switch/start-up

warning

Check:

• Is there an acoustic start-up warning?

• Is an easy access to all emergency stop con-

trols ensured?

Depending on

the application;

brake motors at

least every 3000

hours

Geared motors

Observe the manufacturer's op-

erating instructions!

Gear unit:

• Are there oil stains under the gear unit? If so,

seal the leakage and correct the oil level.

• Check fastening and alignment.

• Unusual noise during operation? Check the

bearings.

Loading...

Loading...