Troubleshooting

Fraction Collector-Related Problems

»

The collection arm does not position

correctly over each collection vessel:

»

Ensure that the racks and tray(s) are aligned correctly.

»

Ensure that the correct rack type has been selected in

the Rack panel for the rack in use (see page 11).

»

Ensure that there is nothing obstructing

or restricting the arm movement.

If this does not solve the problem, the collection arm may

need to be recalibrated. Contact Biotage 1-Point Support.

»

Dripping needle and/or inconsistent dispensing

volumes can be signs of a dirty collect valve.

Please contact Biotage 1-Point Support.

Gradient Problems

Low composition gradient is not correct

To improve gradient accuracy at very low percentages, premix

solvents using the desired final % strong solvent in the weak

solvent and use this as solvent B. Program the gradient from

0 to 100% B using the pre-mixed solvent B.

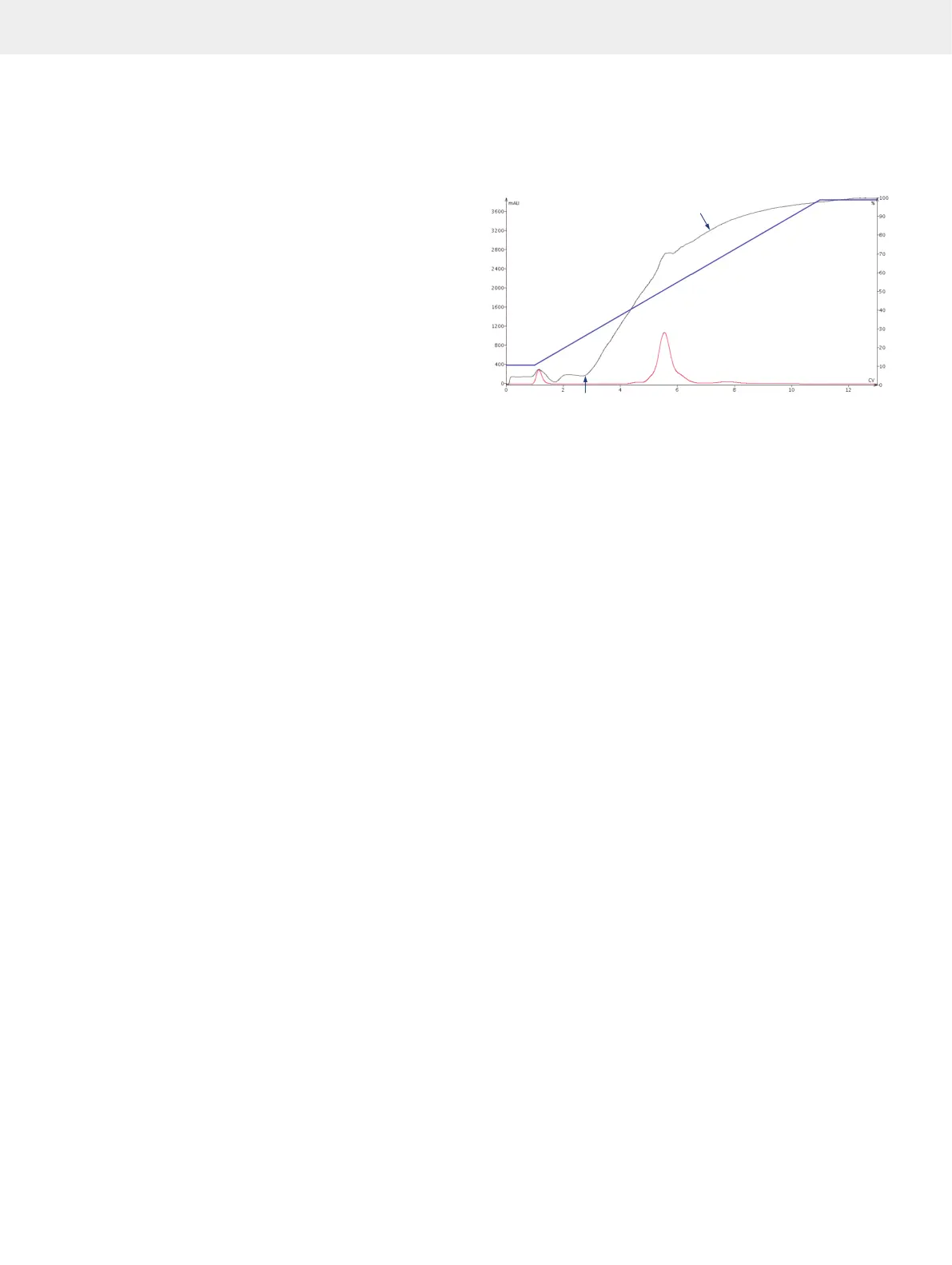

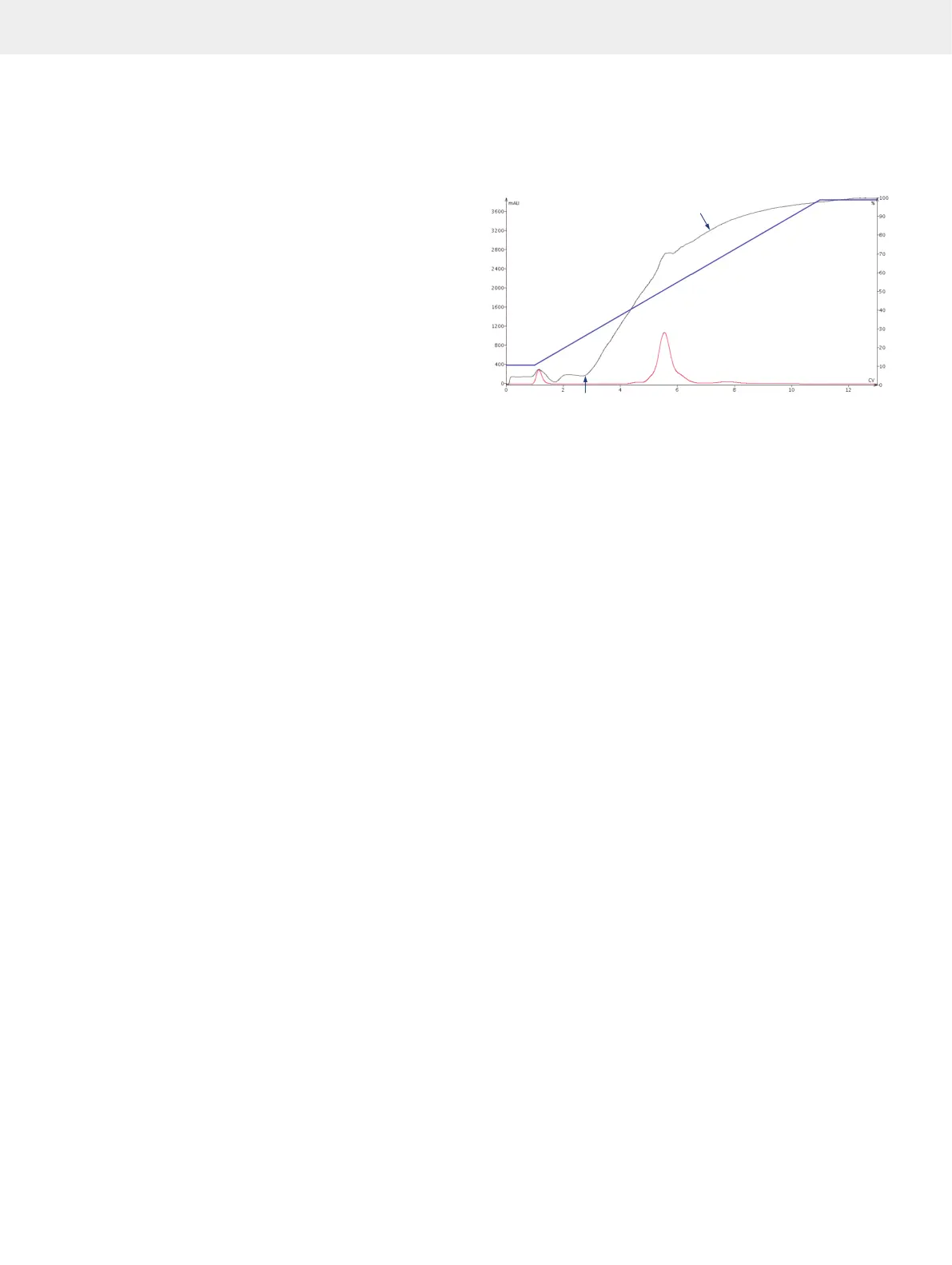

The baseline drift is different from the programmed gradient

Two factors contribute to altering the gradient as observed by

the internal detector:

1. As it takes at least 1 CV for the solvent to pass through the

column and reach the internal detector, the initial front

of the gradient will always be delayed by at least 1 CV

compared to the programmed gradient. A longer gradient

delay may be due to interactions with the silica, where

strong solvent is being selectively retained on the column.

2. The gradient as observed by the internal detector will at

times decline and plateau before the programmed gradient

does. This is due to the detection limit of the internal

detector. Any increase in the concentration of strong solvent

will not be registered as no light is reaching the detector at

those particular wavelengths.

If using a system with a Spektra software license, try performing

the run with the UV Baseline Correction option turned on.

Non-linear behavior due to

detection limit of the detector

Longer delay than expected (approx. 2 CV instead of 1 CV)

due to interactions with the silica, where strong solvent is

being selectively retained on the column

Internal UV Detector-Related Problems

»

No signal. Check that the UV flow cell is correctly

mounted, see step 6 in “Clean the Flow Cell of

the Internal UV Detector” on page 31.

»

Noise may be due to a contaminated flow cell.

Clean the flow cell; see page 31.

»

Drifting baseline may be due to:

»

Contaminated flow cell. Clean the

flow cell; see page 31.

»

Used solvent is absorbing light at the selected

wavelength(s). Change the collection and fractionation

wavelength(s) or turn on the UV Baseline Correction

option (only on systems with a Spektra software license).

»

Defective UV lamp. Contact Biotage 1-Point Support.

»

UV baseline correction is not eliminating drifting baseline:

»

B/C or C/D solvents are used. The UV baseline correction

is only adjusting for absorbance of the A/B solvents.

»

The gradient is modified by the user during the run.

If the gradient is changed outside of its original

boundaries, this is not covered by the standard

UV baseline correction (start to end mix A/B).

Change to full UV baseline correction (start mix to

100% B) in the system settings (see page 27).

»

The modifier percentage is changed by the

user during the run. The UV baseline correction

is based on the original percentage.

»

Missing peaks when using UV baseline correction.

If expected peaks do not show when you have the

UV Baseline Correction option turned on and you are

using solvents that are high-absorbing over a wide

range of wavelengths (e.g. acetone or toluene), try

performing the run without UV baseline correction.

Troubleshooting

Loading...

Loading...