Prepare the System

Setup of Automatic Conversion Between

Normal and Reversed Phase

Selekt automatically converts system solvents from normal to

reversed phase when the following criteria are met:

»

Previous run was performed on the other channel.

»

Previous run was performed using a column intended

for the other chemistry type (reversed/normal

phase) than the one used for the current run.

»

None of the runs use more than two solvents,

i.e. no modifier, solvent C, or solvent D.

»

The strong solvent of the previous run

is still connected to the system.

Automatic conversion is performed between the runs as

follows:

1. The system pumps 100% of the strong solvent of

the previous run via bypass.

2. The system pumps 100% of the strong solvent of

the current run via bypass.

Assign Solvents and Set Reservoir Volumes

When a purification is run, the software determines which

solvent inlets are connected to the solvents used in the run.

Note: For reversed-phase purification with methanol and

water, it is strongly recommended to premix the water with

5% of methanol and degass either through vacuum or

sonication. Degassing of protic solvent blends decreases

out-gassing of entrapped air during gradient elution, which

will impact gradient performance and flow rates.

Note: With solvent and waste monitoring enabled (see

page 27), the capacity and current fluid level must be entered

each time you empty a waste reservoir or refill a solvent.

Note: All four solvent inlets must be primed with solvent to

achieve the specified pump performance.

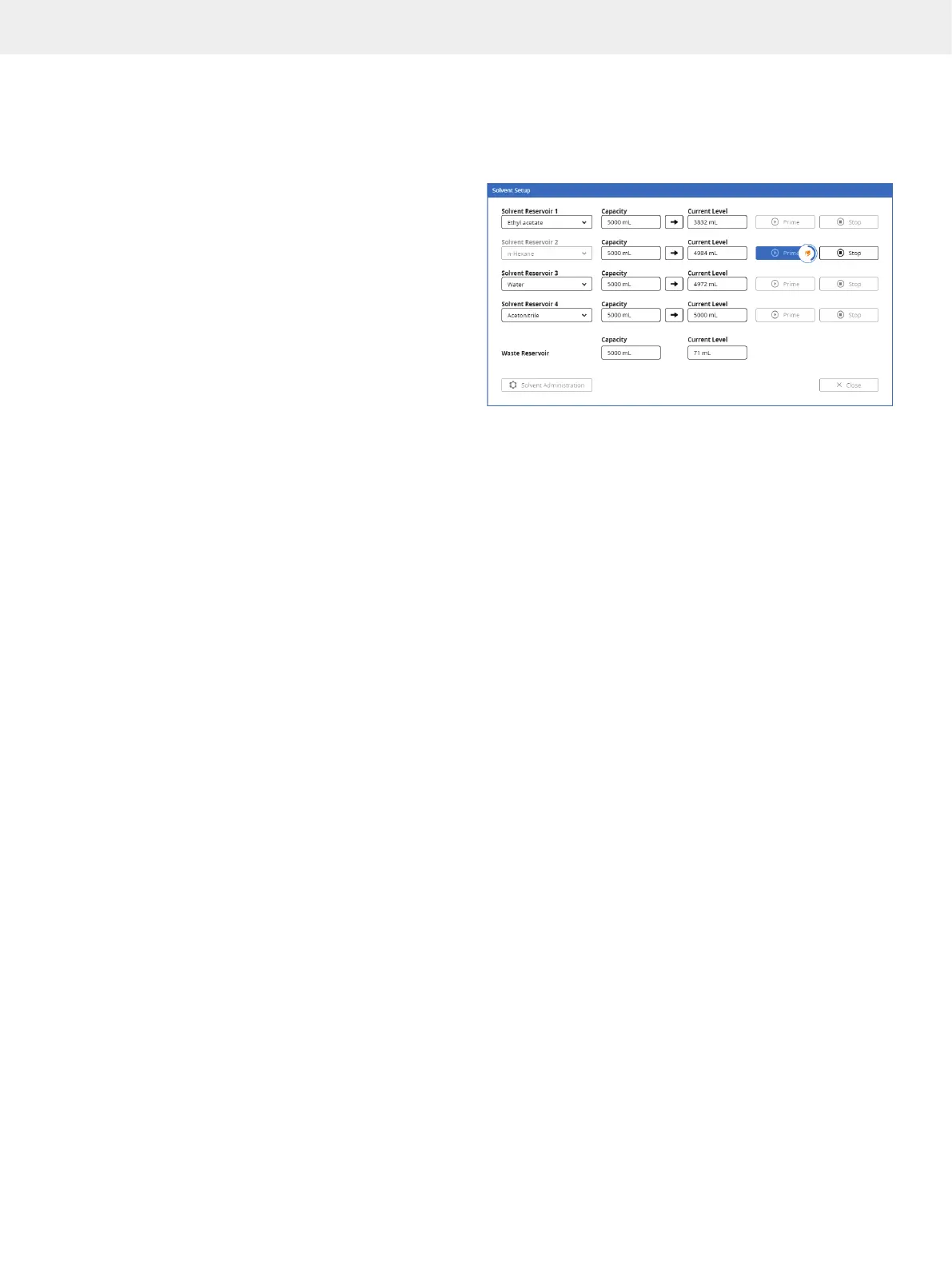

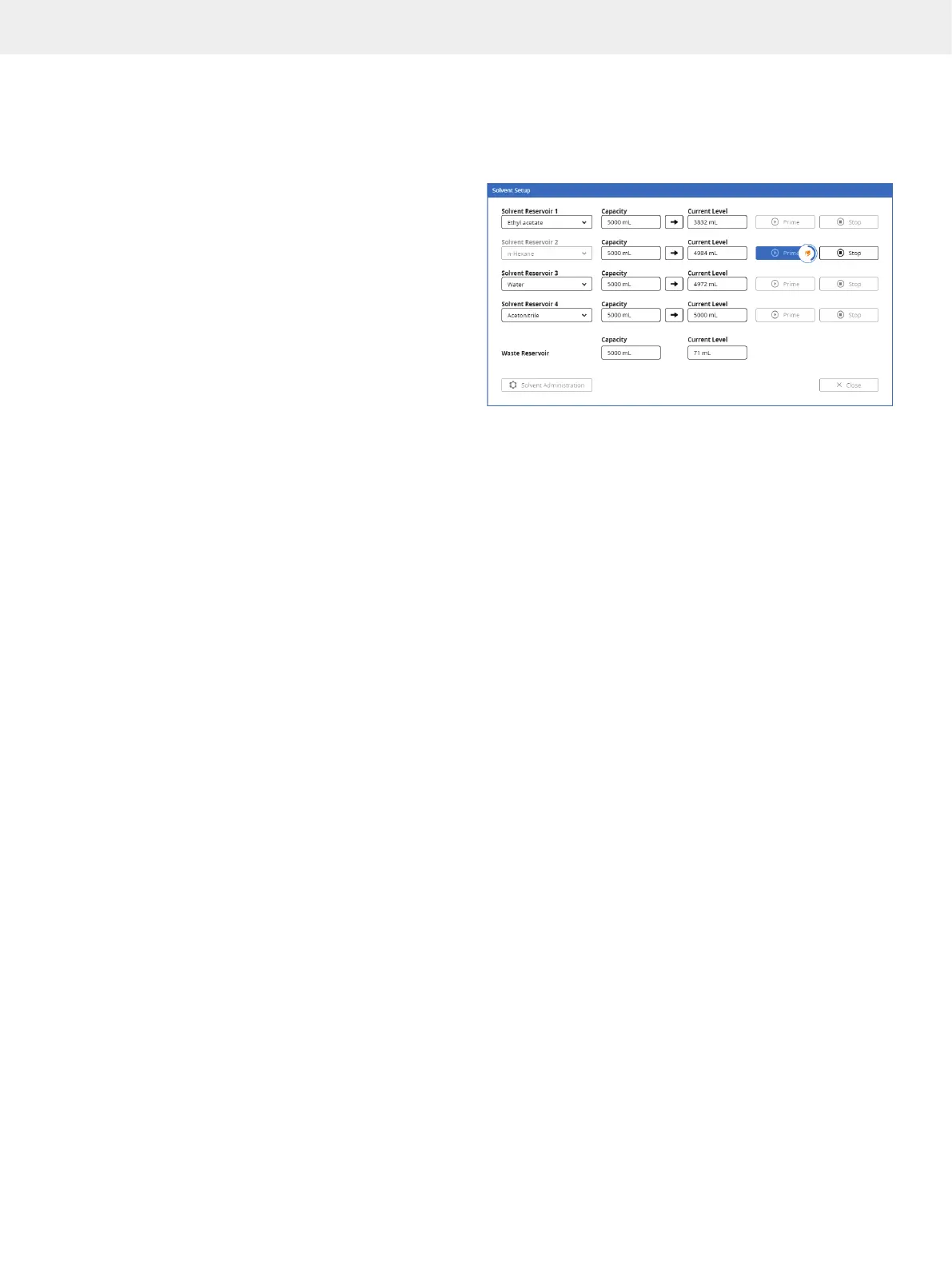

1. In the software, press Menu and then Solvent Setup.

2. Assign a solvent to each solvent inlet using the solvent

drop-down lists (see Figure 17).

To add solvents to the list, press Solvent Administration.

For more information, see page 25.

3. If solvent monitoring is enabled, enter the capacity and

the current solvent level of each solvent reservoir.

4. If waste monitoring is enabled, enter the capacity and

the current waste level of the waste reservoir.

5. Prime the solvent inlets that have been assigned a new

solvent; see below.

Figure 17. The Solvent Setup window with solvent and waste monitoring

enabled.

Prime the Solvent Inlets

Before you start a purification on your system, you might need

to prime the solvent inlets to:

»

Remove any air bubbles from the pump and the

solvent inlets by flushing them with solvents.

»

Empty the solvent inlets of solvents used in the previous

purification and fill them with new solvents.

Note: All four solvent inlets must be primed with solvent to

achieve the specified pump performance.

Note: We recommend to have all solvent reservoirs on the same

physical height to improve accuracy in the solvent mixing.

1. In the software, press Menu and then Solvent Setup.

2. Prime the solvent inlets by pressing the corresponding

Prime buttons (see Figure 17). Note that 27 mL of the

assigned solvent is used for each prime.

Flush the System

If the automatic line flush is disabled on your system (see

page 27), ensure to flush the column flow path before each

run (see page 18).

Loading...

Loading...