58 | Preventive Maintenance

BioTek Instruments, Inc.

Overview

The level of the maintenance required to keep the MicroFlo performing as expected is

highly dependent on several factors, including the type of fluid dispensed, the

frequency of dispensing, and the work habits employed. For example, when

dispensing fluids that can crystallize or harden after use, maintenance activities are

required more frequently. Similarly, when using the 1µL cassette fluids should be

filtered to 50 microns to reduce the chance of tips clogging.

Daily maintenance includes purging the fluid at the end of a dispense run and flushing

the tubing with water (or buffered saline and then water). This is a good practice

whenever the dispenser will be idle for more than an hour, as well as at the end of the

day.

Another important daily requirement is keeping track of the number of plates

processed with a cassette. This is necessary to determine when the cassette has reached

its expected lifetime and is due for replacement or recalibration. Replacement Tubing

Kits, as well as new cassettes are available from BioTek Instruments.

Monthly maintenance requires overall cleaning of the dispenser and its accessories,

and verifying performance to determine if the cassette needs recalibration. Autoclaving

or decontaminating the cassette is also recommended.

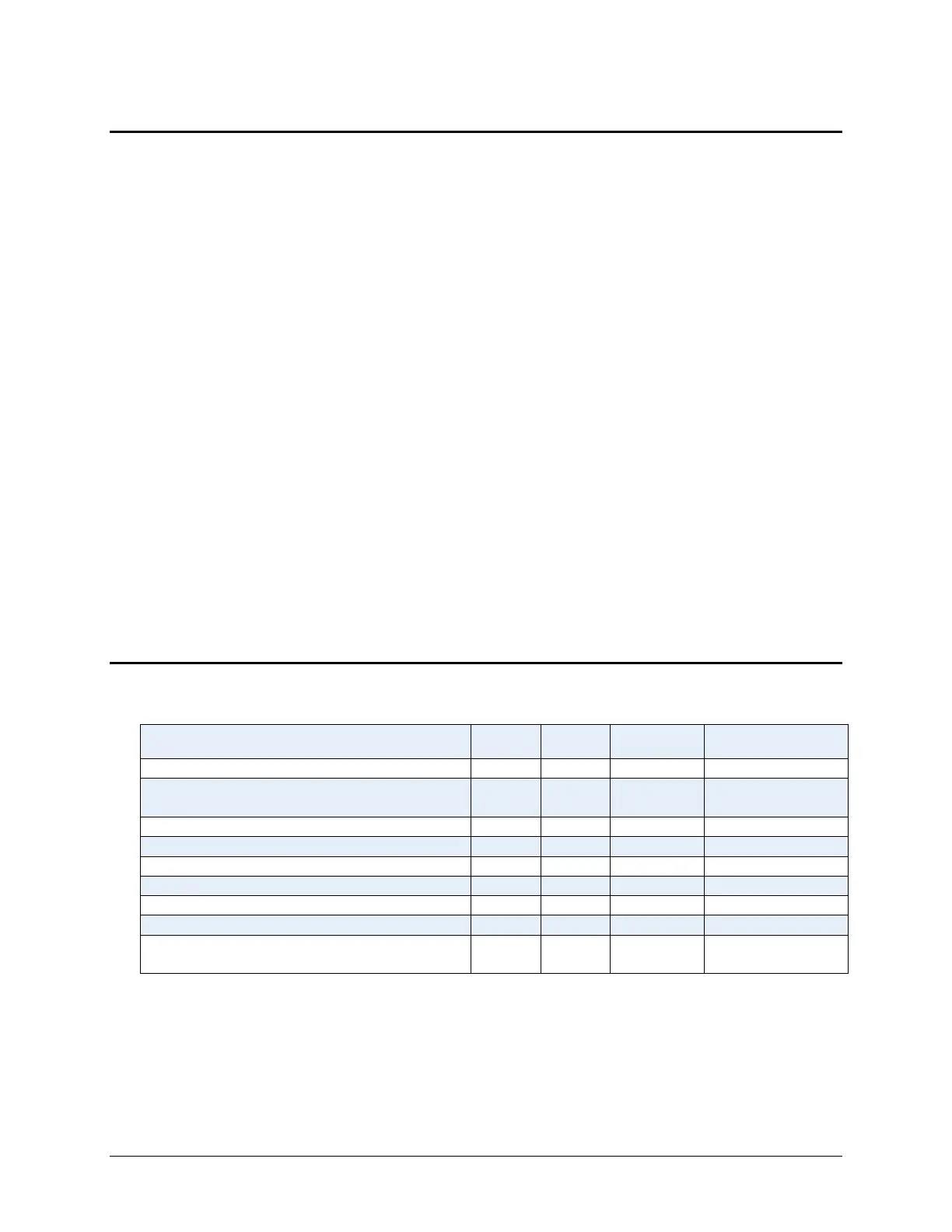

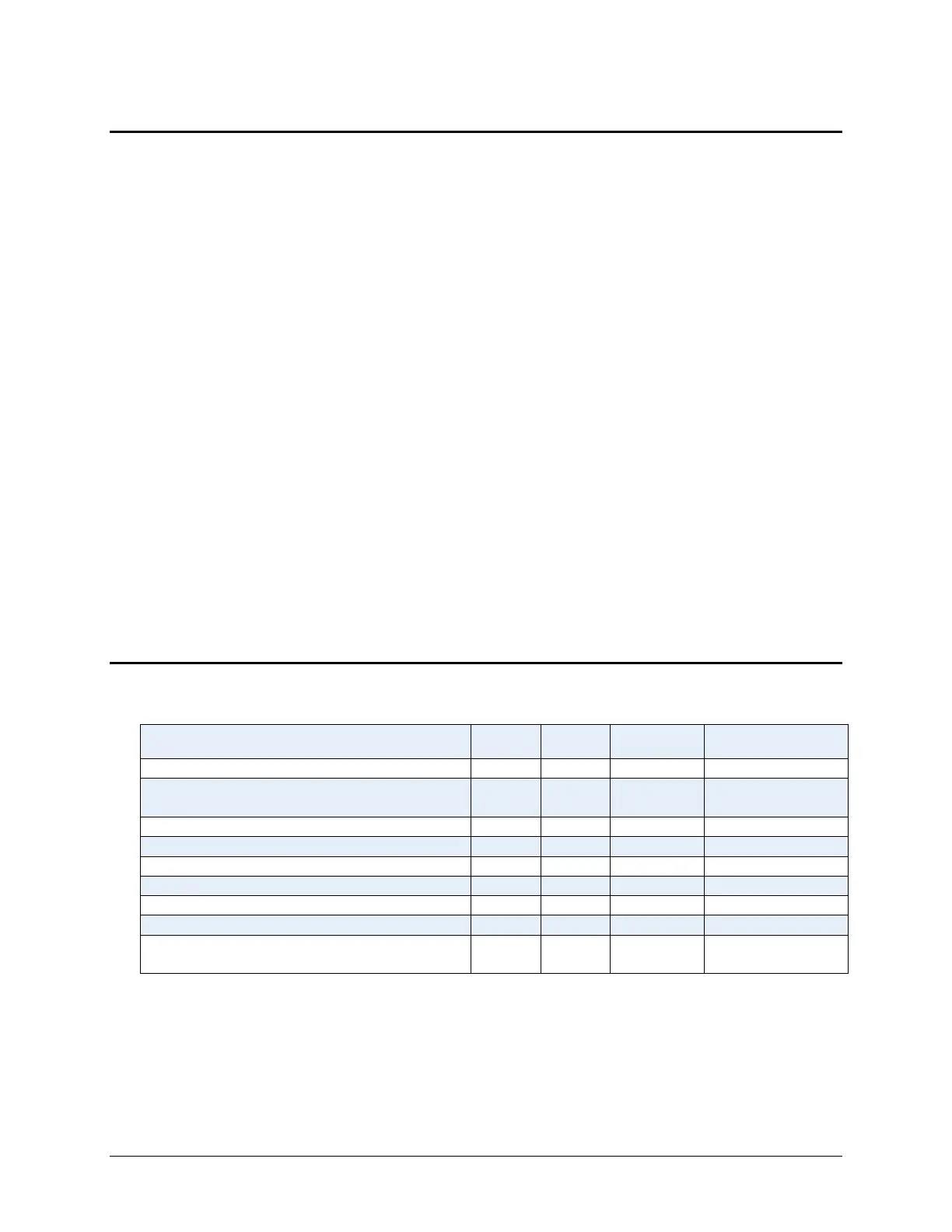

Recommended Maintenance Schedule

Tasks Page Daily

Monthly As needed

Flush Tubing Cassette 59

√

Record The Approximate Number Of

Plates Processed

60

√

Clean Exterior Surfaces 61

√

Clean Prime Trough And Drain Tube 61

√

Verify Performance 62

√

Recalibrate Cassette 65

√

Unclog Dispense Tips 63

√

Replace Tubing 65

√

Decontaminate 66

Before shipping

or storage

Loading...

Loading...