92 | Error Codes

BioTek Instruments, Inc.

Error Codes

This section lists two types of error codes, instrument generated errors and software

errors when using the Liquid Handling Control™ (LHC) software on the computer.

Instrument errors are displayed in a message box by the LHC software, or in the

keypad LCD when running the dispenser manually.

If you haven’t already done so, review the Troubleshooting chapter

for less technical descriptions of the correctable error codes and

corrective action you can take to resolve them.

Instrument Error Codes

When an error code is displayed follow the prompts and try to resolve it. If the

dispenser does not respond as expected, turn off the dispenser. Upon restarting the

dispenser, you should be able to enter commands using the keypad or the LHC. If not,

contact BioTek TAC for support.

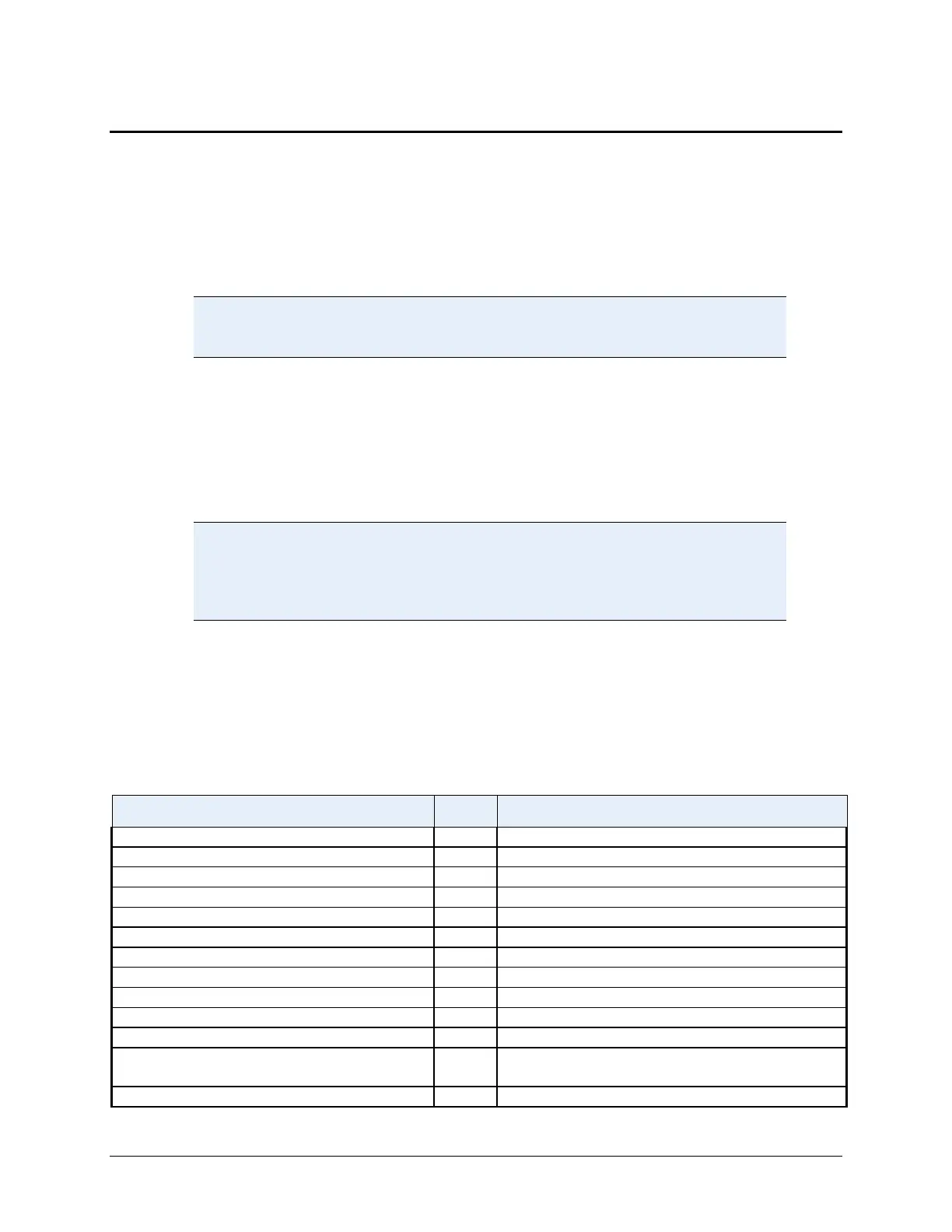

Use the table below to decipher the error code. For example, error

code 304 means the “Pump Cover is not in the safe position (closed

over the pump) for operation.” This meaning is extrapolated from the

error code table: 0304 <4 = Pump Motor> “interlock safety switch is

open.”

Motor Definitions: (shown as <motor> in error table)

Carrier Motor X – 1

Carrier Motor Y – 2

Dispense Arm Motor – 3

Pump Motor – 4

Error Name Code Brief Description

BTI_NO_ERROR 0000 No instrument errors detected

ABORT_ERROR 0100

Task was aborted

MOTOR_SENSOR_ERROR 0200

<motor> didn’t find opto sensor transition

MOTOR_INTERLOCK_ERROR 0300

<motor> interlock safety switch open

MOTOR_VERIFY_ERROR 0400

<motor> failed positional verify

MOTOR_NOT_HOMED_ERROR 0500

<motor> not homed successfully

MOTOR_IN_USE_ERROR 0600 <motor> currently in use

MOTOR_NOT_FOUND_ERROR 0700 <motor> doesn’t exist

CALIBRATION_ERR 0900 Calibration failed

INVALID_PLATE_TYPE_ERR 0A00 Invalid plate type selected

CNFG_DATA_ABSENT_ERR 0C01

Requested config/autocal data absent

CNFG_CHECKSUM_ERR 0C02

Calculated checksum didn’t match saved

checksum

CNFG_PARAMETER_ERR 0C03 Config parameter out of range

Loading...

Loading...