Brookeld Engineering Labs., Inc. Page 29 Manual No. M13-167-A0415

Theprocessofselectingaspindleandspeedforanunknownuidisnormallytrialanderror. An

appropriate selection will result in measurements made between 10-100 on the instrument %

torque scale.Therearetwogeneralrulesthatwillhelpinthetrialanderrorprocess:

1)Viscosityrangeisinverselyproportionaltothesizeofthespindle.

2)Viscosityrangeisinverselyproportionaltotherotationalspeed.

Inotherwords:tomeasurehighviscosity,chooseasmallspindleand/oraslowspeed.Ifthechosen

spindle/speedresultsinareadingabove100%,thenreducethespeedorchooseasmallerspindle.

Experimentationmayrevealthatseveralspindle/speedcombinations

will produce satisfactory results between 10-100%. When this

circumstanceoccurs,anyofthespindlesmaybeselected.

Non-Newtonianuidbehaviorcanresultinthemeasuredviscosityand

yieldstresschangingifthespindleand/orspeedischanged.Seeour

publication,“MoreSolutionstoStickyProblems”,formoredetails.

When viscosity data must be compared, be sure to use the same

test methodology: namely the same instrument, spindle, speed,

container, temperature and test time.

DV3TLVRheometersareprovidedwithasetoffourspindlesand

a narrow guardleg; DV3TRV Rheometers come with a set of six

spindlesandawiderguardleg;DV3THAandDV3THBRheometers

comewithasetofsixspindlesandno guardleg.(SeeAppendixG

formoreinformationontheguardleg.)

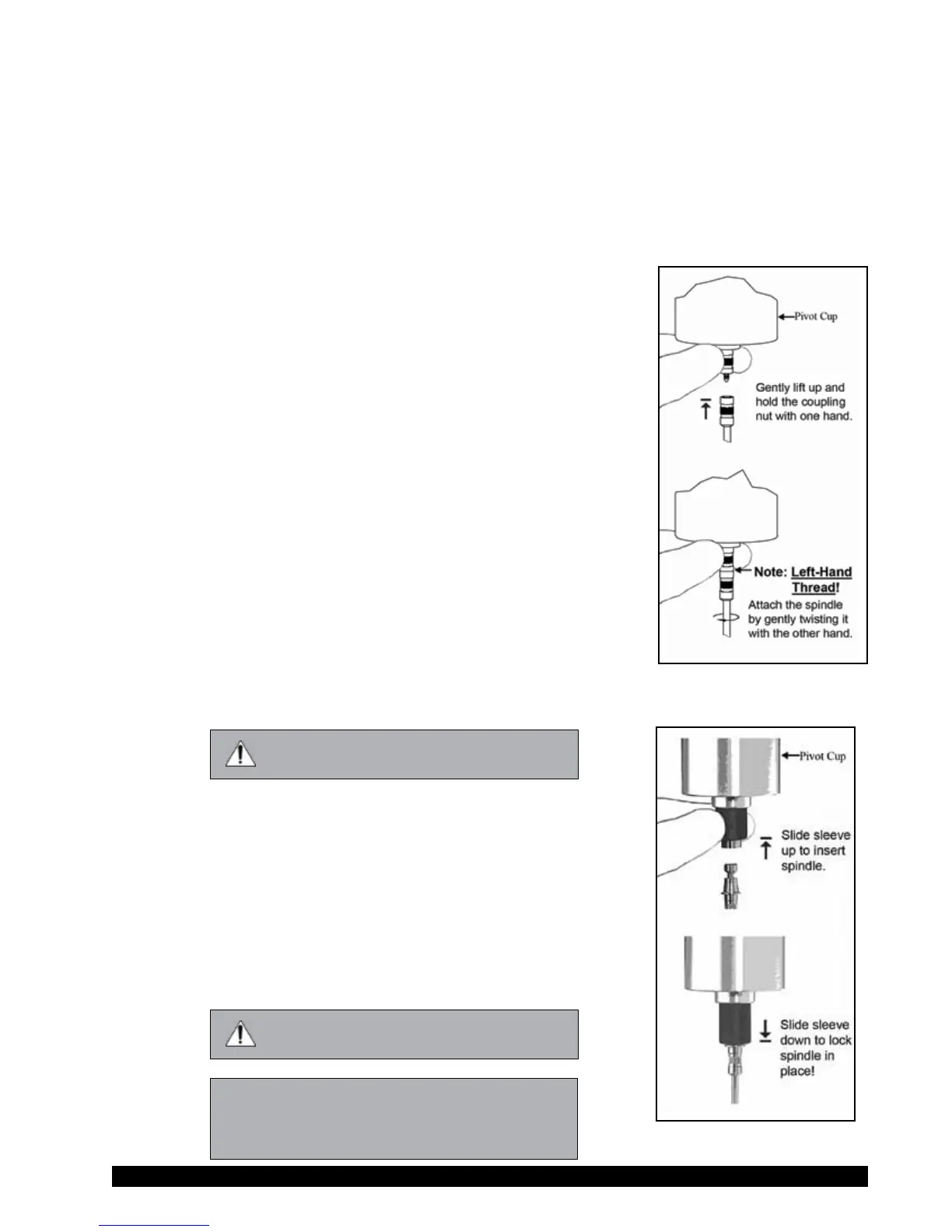

Thespindlesareattachedtotherheometerbyscrewingthemonto

thecouplingnutonthelowershaft(seeFigureIII-4).Notethatthe

spindleshavealeft-handthread.Thelowershaftshouldbesecured

andslightlyliftedwithonehandwhilescrewingthespindletothe

left.Thefaceofthe spindlenutandthematchingsurfaceon the

lowershaftshouldbesmoothandcleantopreventeccentricrotation

ofthespindle.Spindlescanbeidentiedbythenumberontheside

ofthespindlecouplingnut.

ThemotorshouldbeOFF whenever

spindlesarebeingremovedorattached.

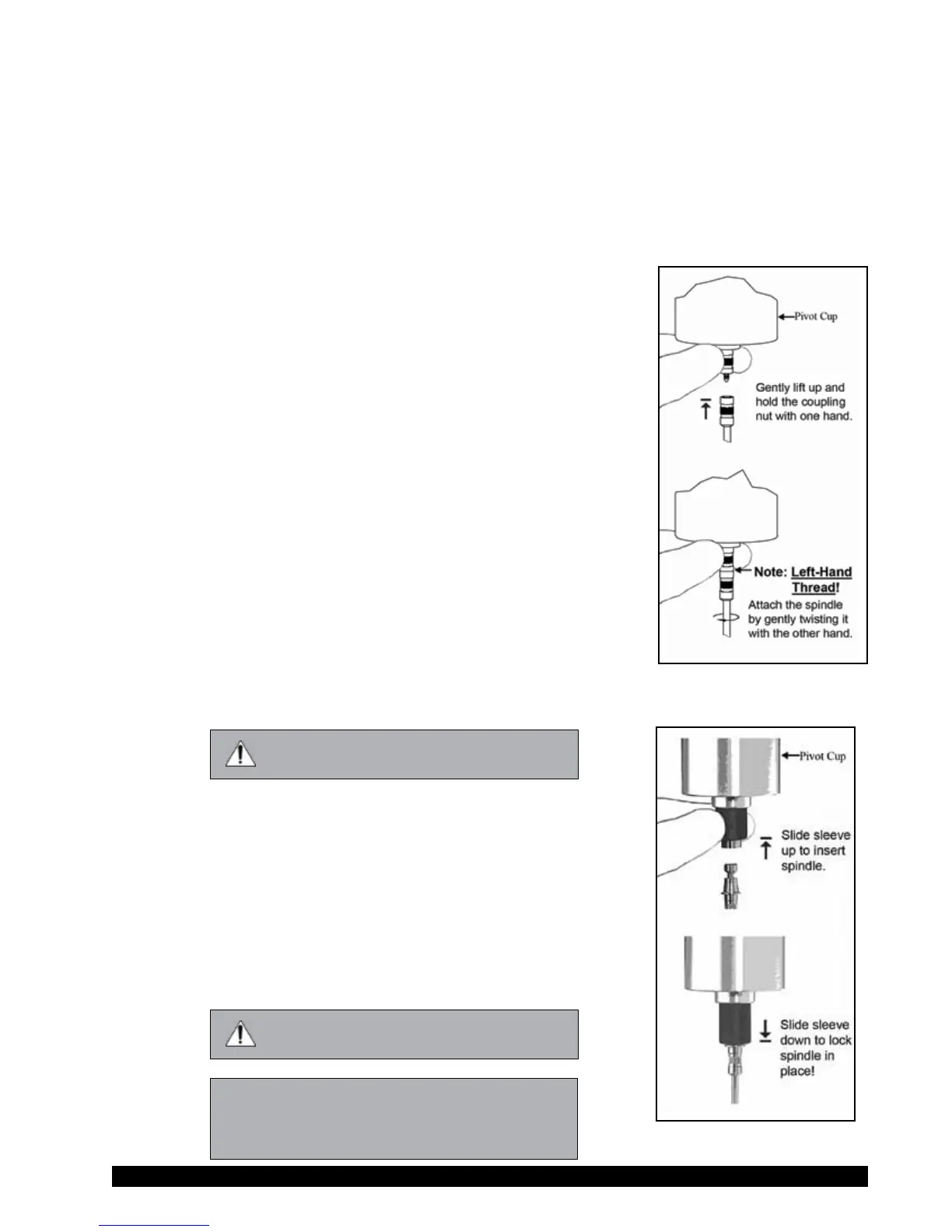

IfyourinstrumenthastheEZ-Locksystem,thespindlesareattached

asfollows:

With one hand holdthespindle,whilegentlyraisingthespring-

loadedoutersleevetoitshighestpositionwiththeotherhand,as

shown in Figure III-5. Insert the EZ-Lock SpindleCoupling so

thatthebottomofthecouplingisushwiththebottomoftheshaft,

andlowerthesleeve.Thesleeveshouldeasilyslidebackdownto

holdthespindle/couplingassemblyinplaceforuse.[Spindlescan

beidentiedbyentrycode;lookforthenumberonthesideofthe

EZ-Lockspindlecoupling.]

ThemotorshouldbeOFF whenever

spindlesarebeingremovedorattached.

Note: KeeptheEZ-LockSpindleCouplingand

outersleeveascleanaspossibleandfree

from debris that could become lodged

insidetheadapter.

Figure III-5

Figure III-4

Loading...

Loading...