Brookeld Engineering Labs., Inc. Page 90 Manual No. M13-167-A0415

Appendix A - Cone/Plate Rheometer Set-Up

ThisCone/Plate version ofthe DV3T usesthe same operatinginstruction procedures asdescribed

inthismanual.However,the“gap”betweentheconeandtheplatemustbeveried/adjustedbefore

measurementsaremade.Thisisdonebymovingtheplate(builtintothesamplecup)uptowardsthe

coneuntilthepininthecenteroftheconetouchesthesurfaceoftheplate,andthenbyseparating

(lowering)theplate0.0005inch(0.013mm).

WhenoperatingtheCone/Plateatelevatedtemperature,thegapmustbesetwiththecupandspindle

equilibratedatthetemperaturerecommended.MaximumtemperatureforCone/Plateoperationis80ºC.

Maximumoperationaltemperatureofsamplecupis100

ºC.Personalprotectionisrecommendedwhen

controllingtotemperaturesabove80ºC.

Note: MicrometerAdjustmentRingwillbecomehotwhencontrollingsample

cupattemperaturesabove50ºC.

ProgrammableDV3TCone/PlateRheometers,S/N50969andhigher,haveanElectronicGapSetting

feature.Thisfeatureenablestheusertoeasilyndthe0.0005inchgapsettingthatwasestablishedat

Brookeldpriortoshipment.

Brookeldrecommendsthatthemaximumparticlesizeinthesamplematerialformeasurementwith

cone/plategeometrybelessthan5timesthegapsettings.Amoreconservativeapproachistolimitthe

maximumparticlesizetolessthan10timesthegapsetting.

ThefollowinginformationexplainshowtosettheElectronicGapandverifycalibrationoftheDV3T

Rheometer.

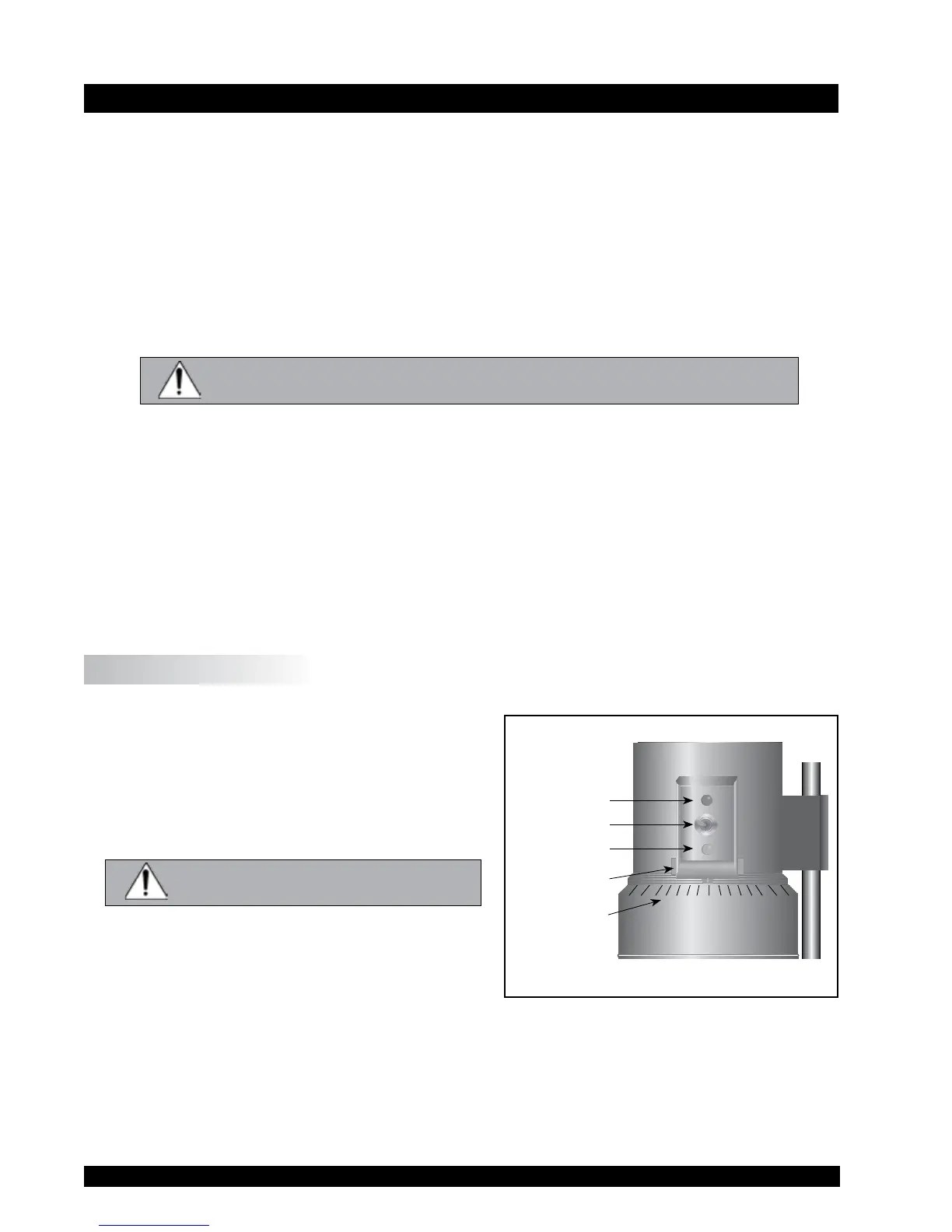

A.1 Electronic Gap Setting Features

TOGGLE SWITCH allows you to enable/disable the

ElectronicGapSettingFeature:leftpositionisOFF

(disabled),rightpositionisON(enabled).

PILOT LIGHT isthered(LED)light;whenilluminated,

itmeanstheElectronicSettingFunctionissensing

(enabled).

Note: Be sure the light is off before

introducingthetestsample.

CONTACT LIGHTistheyellow(LED)light;whenitrst

turnson,the“hitpoint”hasbeenfound.

SLIDING REFERENCE MARKERisusedafterndingthe

“hit point;” it is the reference for establishing the

0.0005inchgap.

MICROMETER ADJUSTMENT RINGisusedtomovethecupupordowninrelationtotheconespindle.

Turningtheringleft(clockwise)lowersthecup;turningitright(counterclockwise)raisesthecup.

Eachlineontheringrepresentsonescaledivisionandisequivalentto0.0005inchmovementof

theplaterelativetothecone.

Pilot Light

(red)

Toggle Swtich

Contact Light

(yellow)

Sliding Reference

Marker

Micrometer

Adjustment Ring

Figure A-1

Loading...

Loading...