Brookeld Engineering Labs., Inc. Page 31 Manual No. M13-167-A0415

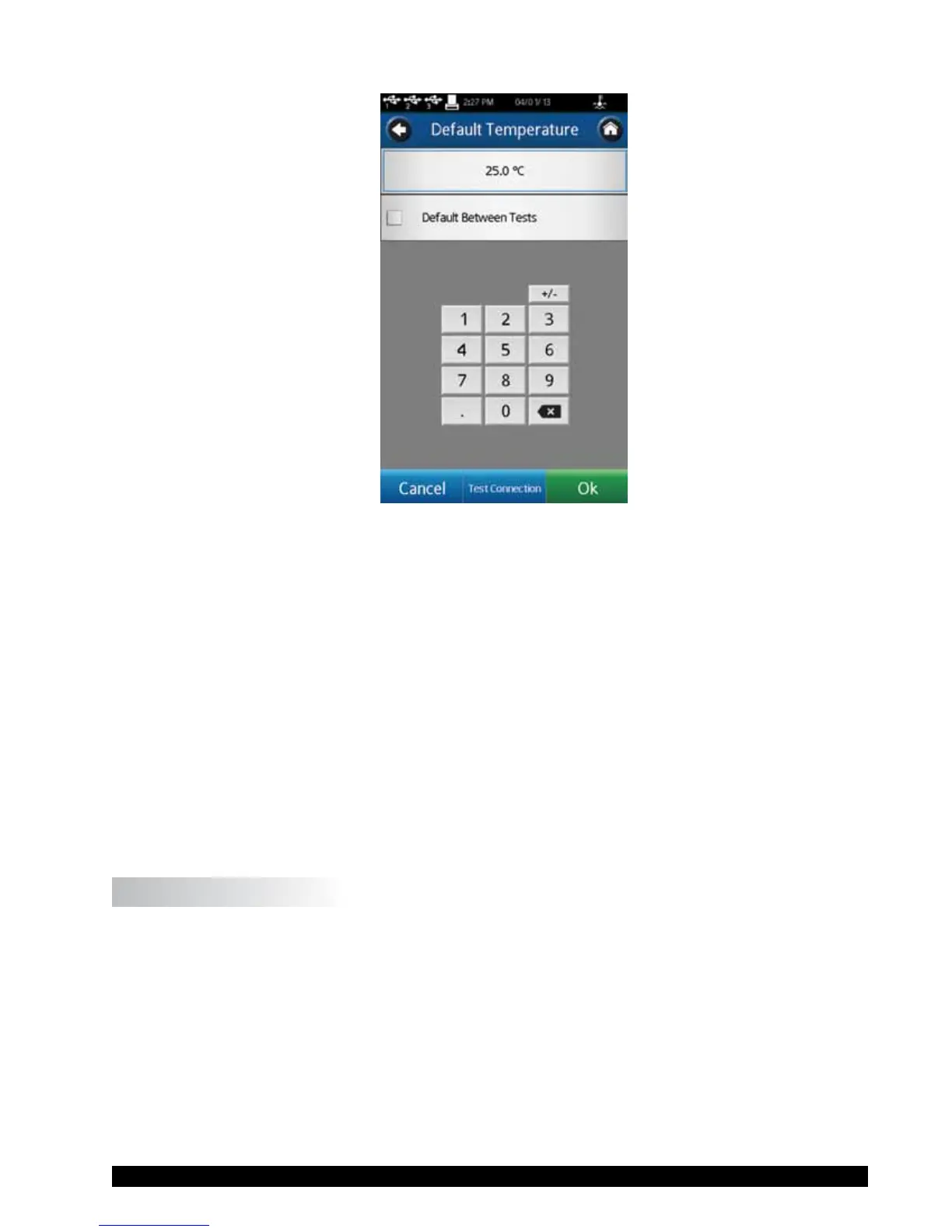

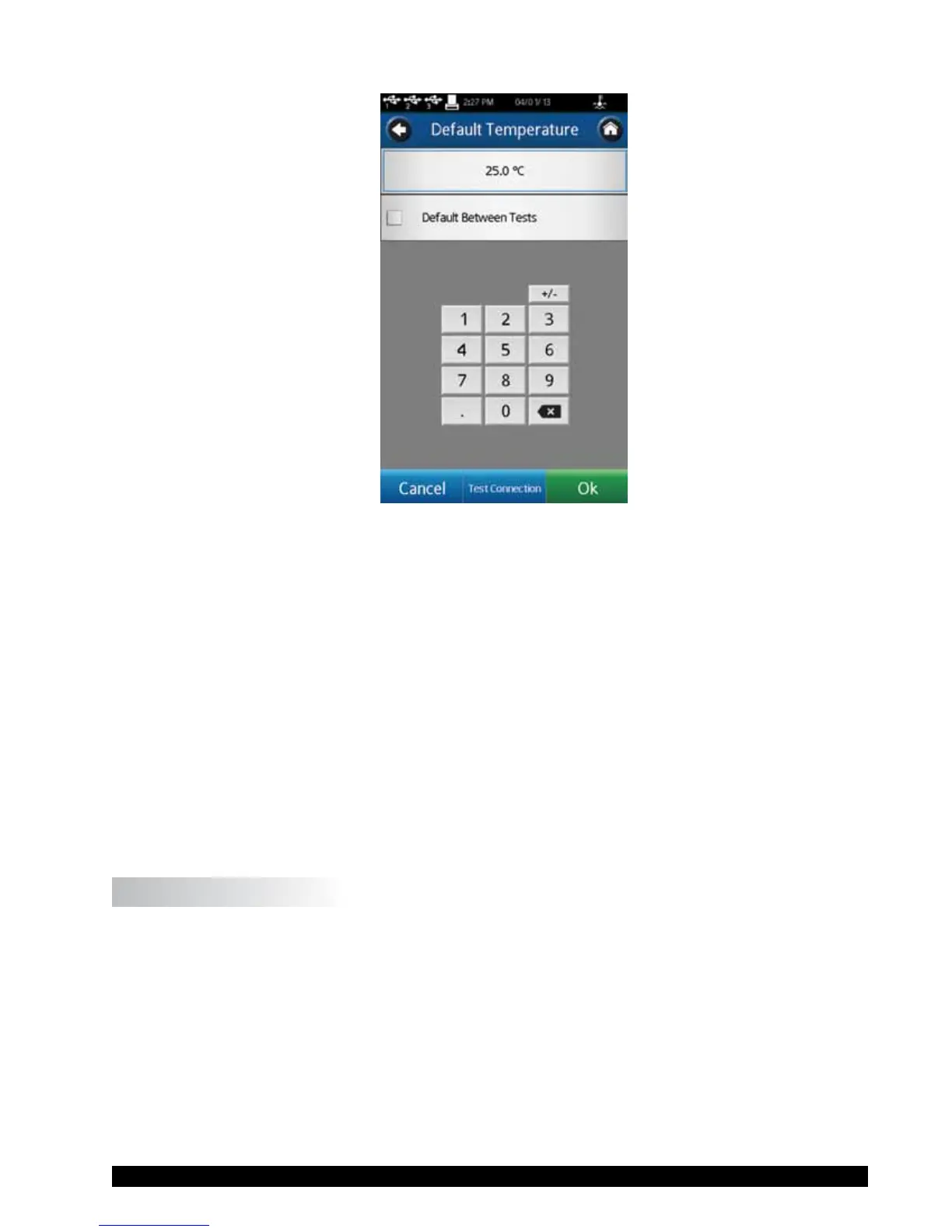

Figure III-7

InitiatetemperaturecontrolbypressingtheTestConnection.Theconnectionstatuswillbeconrmed

withamessageboxandtheappearanceofthebathiconinthestatusbar(seeSectionII.3).

The Default Temperature is the temperature value that the control device will return to at the

conclusionofaTest.Thisvalueissetonlyifthecheckboxischecked.Whenthecheckboxis

unchecked,thetemperaturecontrollerwillholdatthelastsetpointusedintheTest.

TIP:Whenatestinvolvesseveraltemperaturesetpoints,settheDefaultTemperaturetotherst

setpointusedintheTest.ThiswillreducethetransitiontimefromoneTestruntothenext

Testrun.

NotethattemperaturecontrollerscanalsobecontrolledthroughtheRheocalcTsoftwarewhen

theyareconnectedtothecomputerusingthepropercable.TheThermoselrequirestheHT-106

cable(RS-232),availablefromBrookeld.Thewaterbathrequiresthe225-173cable(RS-232),

whichcomeswiththebath.

III.6 Multiple Data Points

Themajorityofviscosityandyieldstressmeasurementsaremadeatthequalitycontrolleveland

oftenconsistofasingledatapoint.Thetestisconductedwithonespindleatonespeed.Thedata

pointisausefulbenchmarkforthego/no-godecisioninaproductionsetting.TheDV3Tcanbe

usedforsinglepointmeasurement.

Manyuidsexhibitacharacteristicchangeinviscosityandyieldstresswithachangeinapplied

force.Thisnon-Newtonianowbehavioriscommonlyseeninpaints,coatingsandfoodproducts

asadecreaseinviscosityasshearrateincreasesoranincreaseinyieldstressasarotationalspeed

increases.Thisbehaviorcannotbedetectedorevaluatedwiththesinglepointmeasurement.

Non-Newtonianowisanalyzedthroughthecollectionofviscositydataoverarangeofshearrates

andthegenerationofagraphofviscosityversusshearrate(arheogram).Thisinformationwill

Loading...

Loading...