Brookeld Engineering Labs., Inc. Page 48 Manual No. M13-167-A0415

IV.3 Selecting a Spindle/Speed

TheDV3Thasthecapabilityofmeasuringyieldstressoveranextremelywiderange.Forexample,

theDV3TRVcanmeasureuidswithintherangeof0.5-400Pa.Thisrangeisachievedthrough

theuseofseveralvanespindlesovermanyspeeds.SeeAppendixBfordetails.

Theprocessofselectingaspindleandspeedforanunknownuidisnormallytrialanderror. An

appropriate selection will result in measurements made between 10-100 on the instrument %

torque scale.Therearetwogeneralruleswillhelpinthetrialanderrorprocess:

1)Viscosityrangeisinverselyproportionaltothesizeofthespindle.

2)Viscosityrangeisinverselyproportionaltotherotationalspeed.

Inotherwords:tomeasurehighyield,chooseasmallspindleand/oraslowspeed.Ifthechosen

spindle/speedresultsinareadingabove100%,thenreducethespeedorchooseasmallerspindle.

Experimentation may reveal that several spindle/speed combinations will produce satisfactory

resultsbetween10-100%.Whenthiscircumstanceoccurs,anyofthespindlesmaybeselected.

When yield data must be compared, be sure to use the same test methodology: namely the

same instrument, spindle, speed, container, temperature and test time.

VanespindlesareoptionalequipmentandarenotpartofthestandardDV3Tpackage.DV3TLV

Rheometersareprovidedwithasetoffourspindlesandanarrowguardleg;DV3TRVRheometers

comewithasetofsixspindlesandawiderguardleg;DV3THAandDV3THBRheometerscome

withasetofsixspindlesandno guardleg.(SeeAppendixGformoreinformationontheguardleg.)

Do not use the guard leg with vane spindles.

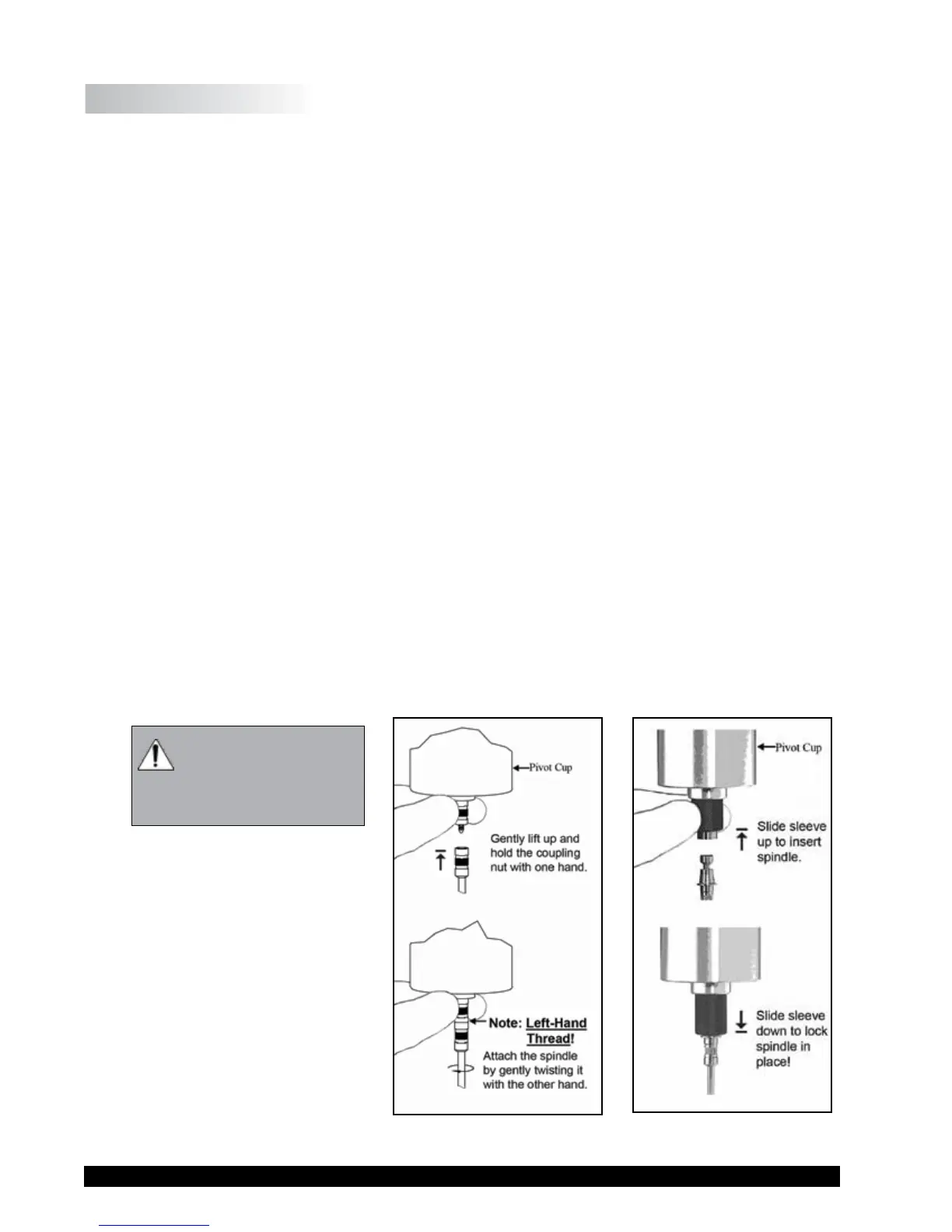

Thespindlesareattachedtotherheometerbyscrewingthemontothecouplingnutonthelower

shaft(seeFigureIV-1).Notethatthespindleshavealeft-handthread.Thelowershaftshould

besecuredandslightlyliftedwithonehandwhilescrewingthespindletotheleft.Thefaceof

thespindlenutandthematchingsurfaceonthelowershaftshouldbesmoothandcleantoprevent

eccentricrotationofthespindle.Spindlescanbeidentiedbythenumberonthesideofthespindle

couplingnut.

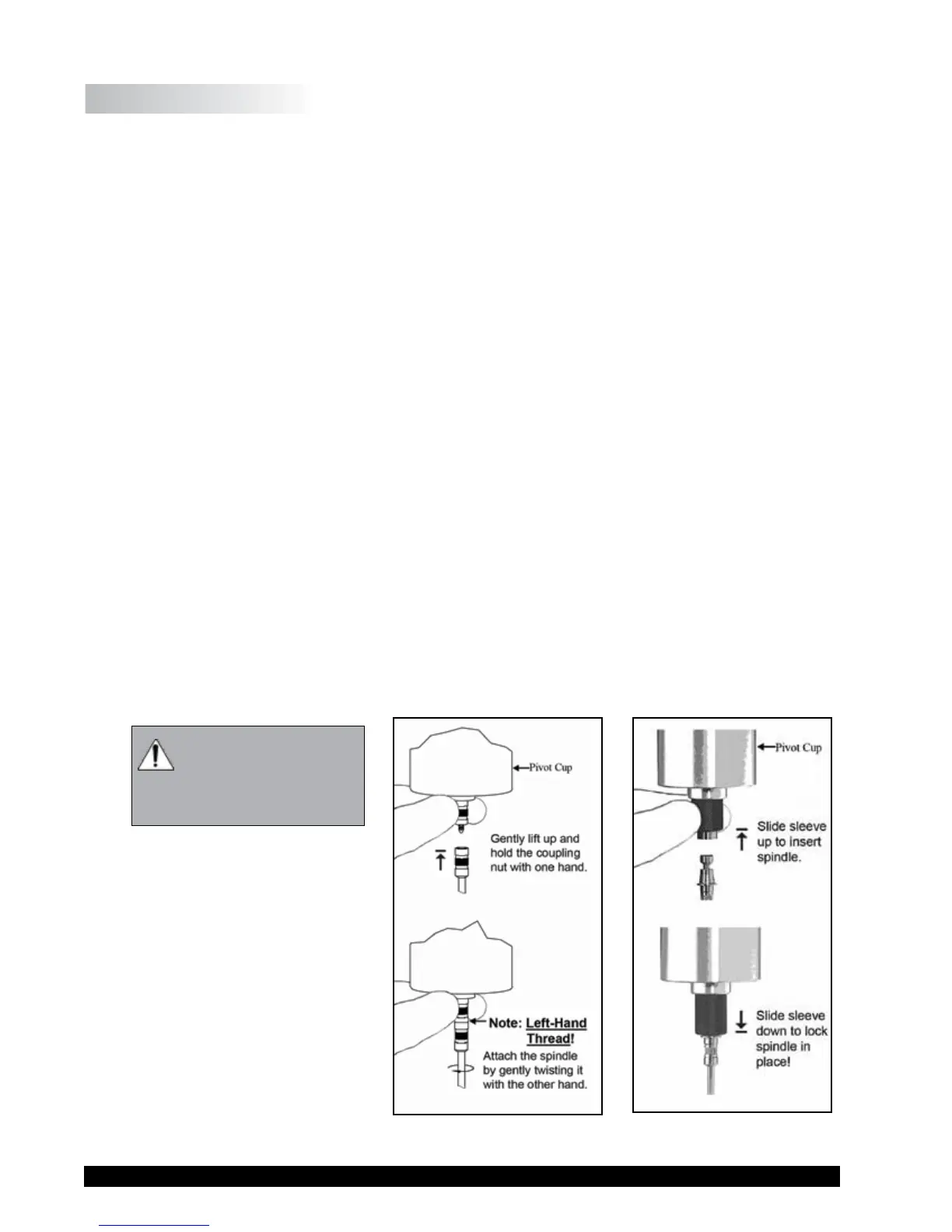

IfyourinstrumenthastheEZ-Lock

system,thespindlesareattachedas

follows:

Withonehandholdthespindle,while

gentlyraisingthespring-loadedouter

sleeve to its highest position with

theotherhand,asshowninFigure

IV-2. Insert the EZ-Lock Spindle

Couplingsothatthebottomofthe

couplingisushwiththebottomof

theshaft,andlowerthesleeve.The

sleeveshouldeasilyslidebackdown

toholdthespindle/couplingassembly

The motor should

be OFF whenever

spindles are being

removedorattached.

Figure IV-1 Figure IV-2

Loading...

Loading...