4 - 9

Adjustment (Main Unit)

Inspection and

Adjustment

Needle bar height adjustment

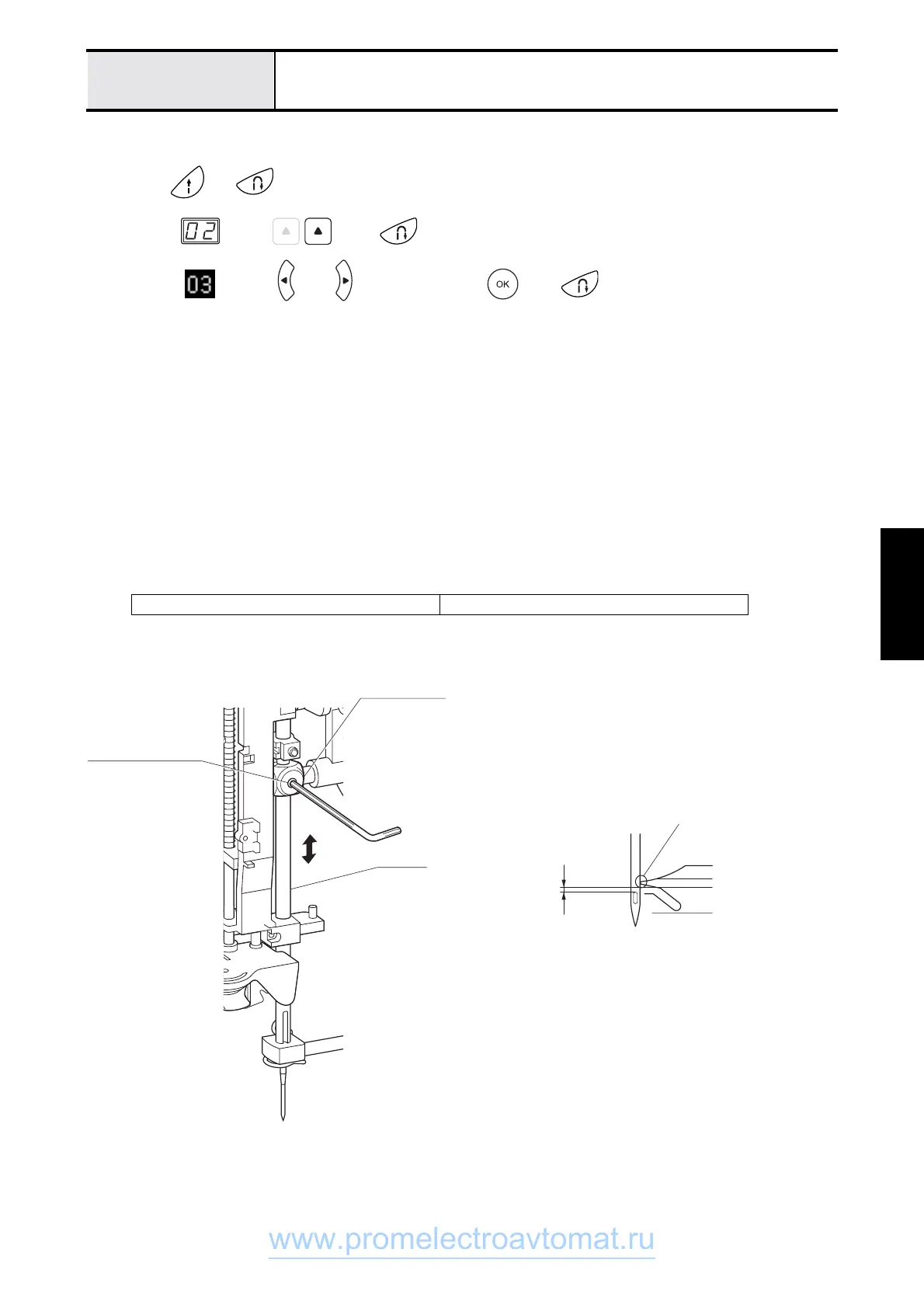

1. Attach the operation PCB assy. flat cable and power PCB assy. lead wire connector to the main PCB assy., and

attach the front cover to the arm bed.

2. Press and while turning the power on (the buzzer will sound four times, and test mode will start).

3. <S2>

Select using , press once, and set the needle bar to the left base line position.

<S3>

Select using or , and after pressing press once, and set the needle bar to the left

base line position.

4. Turn off the power.

5. Lower the presser foot lifter.

6. Turn the pulley by hand until the right edge of the needle and the tip of the outer rotary hook meet (pulley turned

counterclockwise).

7. Loosen the set screw (socket (CP) M4X4) in the needle bar block

8. Adjust the height of the needle bar for 1.0 – 1.4 mm between the top of the needle hole and lower edge of the

outer rotary hook tip.

NOTE •Needle hole turned forward

9. Fully tighten set screw (socket (CP) M4X4.

10. Perform 4 - 23 "Adjust the needle thread block."

Set screw, socket (CP) M4X4

torque 0.78 – 1.18 N-m

Needle block

crew, socket 4 × 4

Iron bar

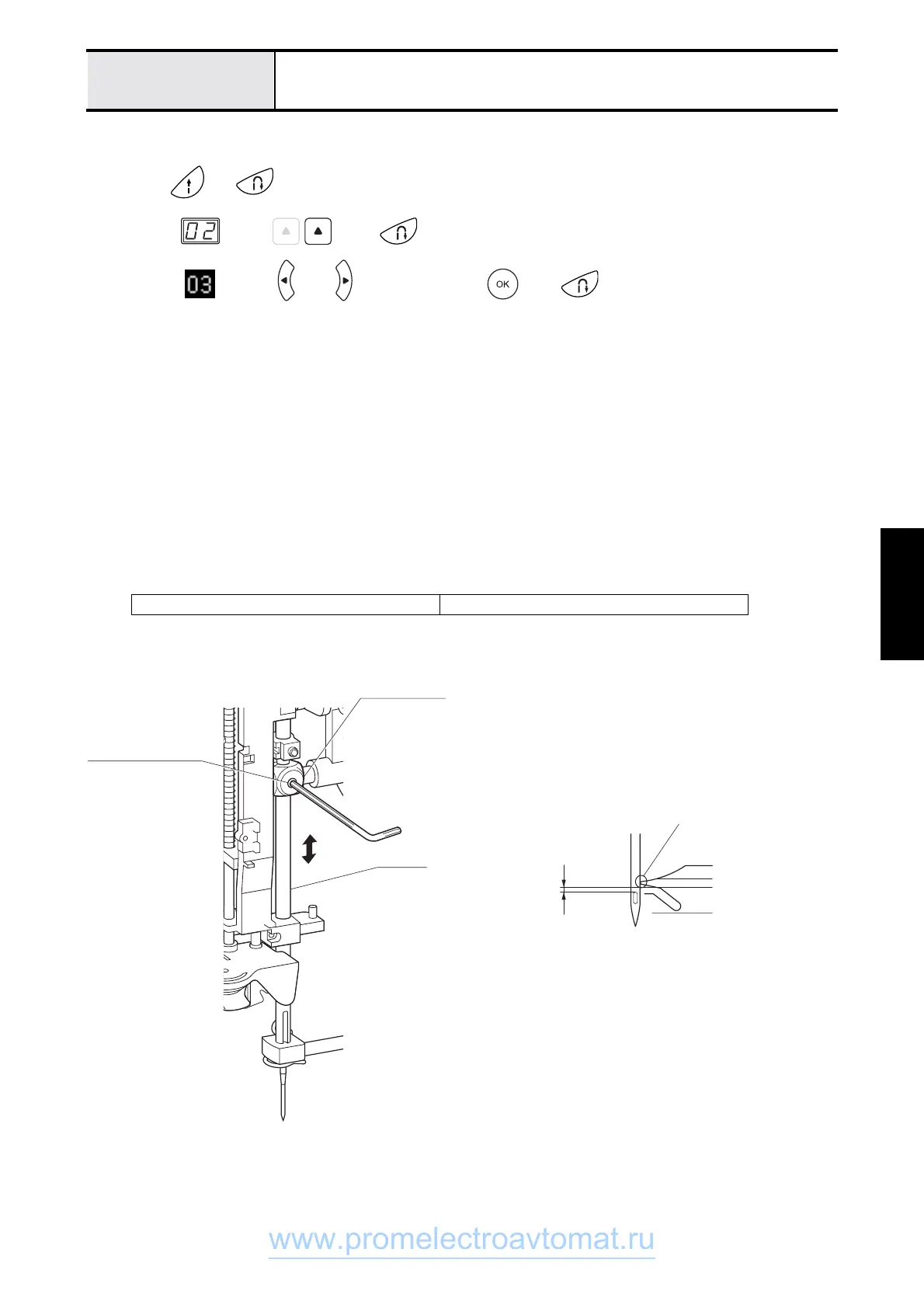

1.0 - 1.4mm

Right edge of needle

and tip meet

www.promelectroavtomat.ru

Loading...

Loading...