4 - 11

Adjustment (Main Unit)

Inspection and

Adjustment

Cassette threading height adjustment

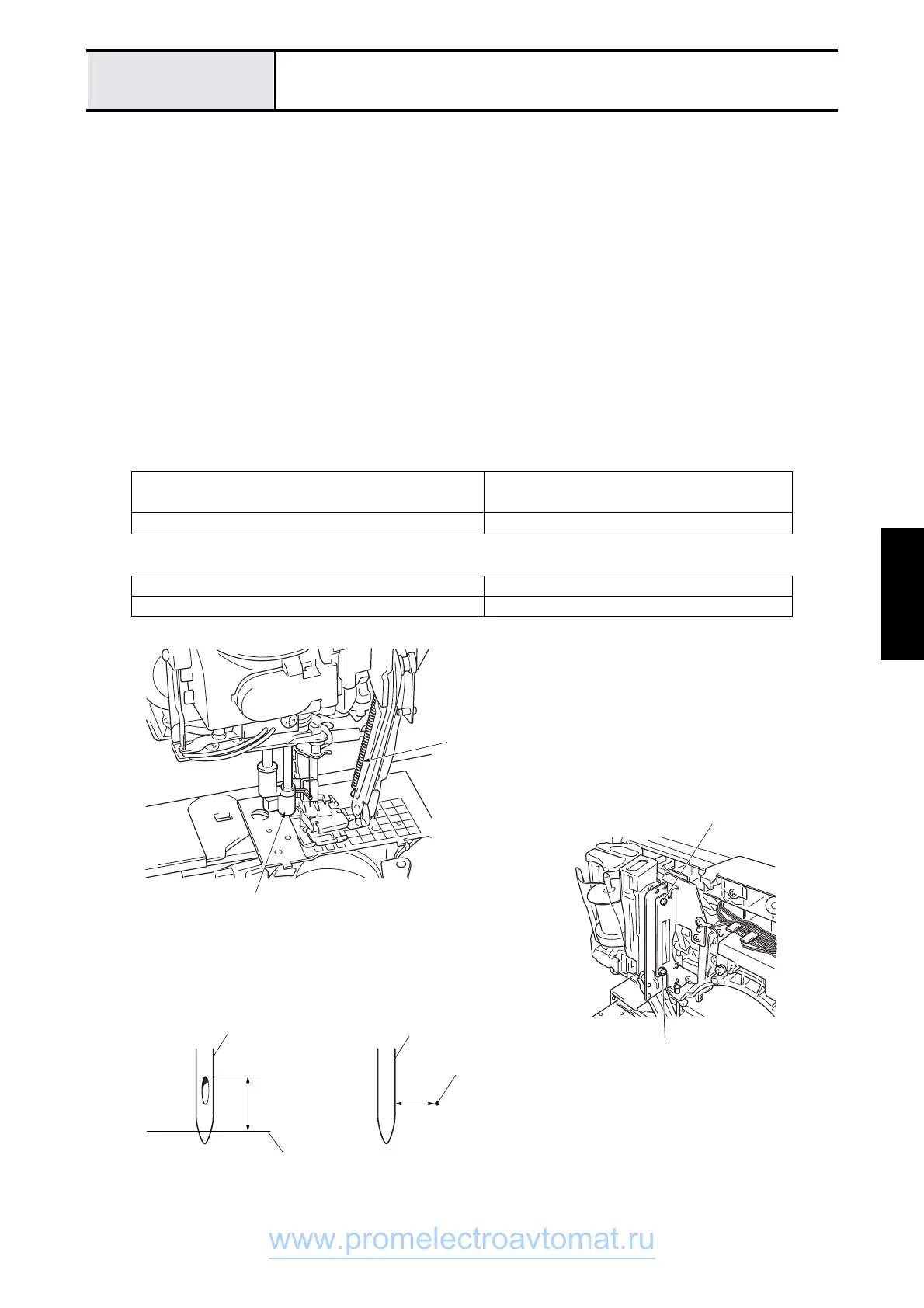

1. Perform 4 - 23 "Adjust the needle thread block."

2. Attach the operation PCB assy. flat cable and power PCB assy. lead wire connector to the main PCB assy., and

attach the front cover to the arm bed. (without screwing it on).

3. Turn the power on.

4. Turn the pulley counterclockwise by hand, and stop just before the LED lamp changes from green to red

(green light/needle up stop position).

5. Turn off the power.

6. Remove the front cover.

NOTE •Be careful that the pulley position does not shift at this time.

7. Prepare a cassette (set up the thread)

8. Insert the cassette, and lower the shuttle to the lowest point (Position where the shuttle is extended to the lowest

point and the threading hook starts to move).

9. Loosen the screw, bind M3X4, and screw, pan (S/P washer) M3X6, and adjust the position of the thread guide

base assy.

10. Fully tighten screw, bind M3X4, and screw, pan (S/P washer) M3X6.

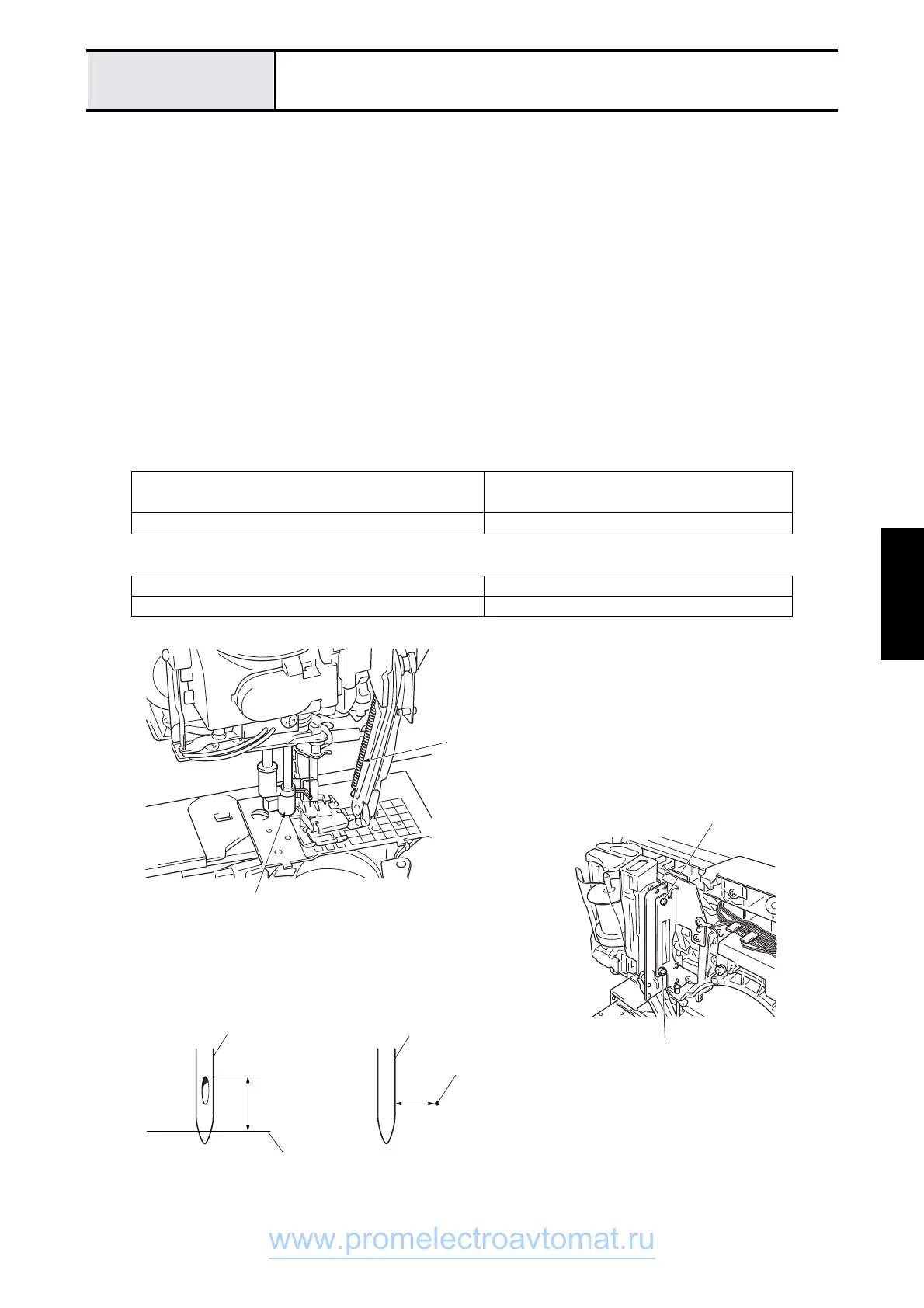

Distance from the upper edge of the needle hole to

the thread

2.1 +/-0.3 mm

Distance from the front of the needle to the thread 0.8 +/-0.2 mm

Screw, bind 3x4

, torque 0.57 - 0.79 N-m

Screw, pan (S/P washer) M3X6

torque 0.57 - 0.79 N-m

Screw, bind 3 × 4

Set screw, socket 3 × 6

Shuttle extended all the way

Thread hook starts to move

Thread

Needle

Front view Side view

Needle

Thread

2.1 ± 0.3mm

0.8 ± 0.2mm

www.promelectroavtomat.ru

Loading...

Loading...