2-116

Confidential

4.8 Troubleshooting for Fuser Unit Problems

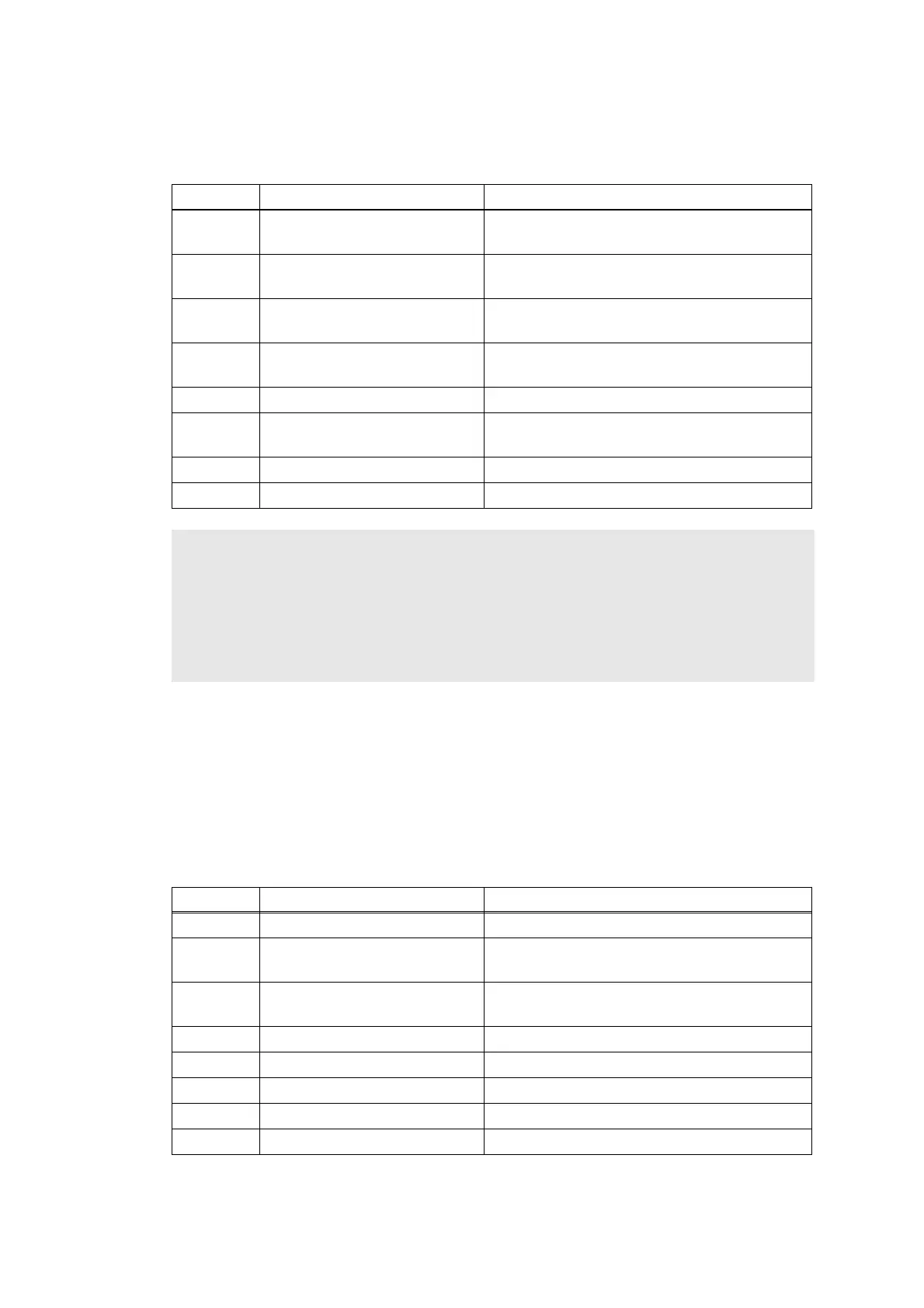

4.8.1 Fuser unit failure

4.9 Troubleshooting for LED ASSY Problems

4.9.1 LED ASSY failure

<User Check>

• Turn ON the power switch, then open the top cover and the back cover. Leave the machine

for a while to remove condensation.

Step Cause Remedy

1

Connection failure of the

center thermistor harness

Reconnect the center thermistor harness.

2

Connection failure of the side

thermistor harness

Reconnect the side thermistor harness.

3

Connection failure of the

heater harness

Reconnect the heater harness.

4

Connection failure of the eject

sensor harness

Reconnect the eject sensor harness.

5 Eject sensor PCB failure Replace the eject sensor PCB.

6

Low-voltage power supply

PCB failure

Replace the low-voltage power supply PCB.

7 Fuser unit failure Replace the fuser unit.

8 Main PCB failure Replace the main PCB.

Note:

• Turn the power switch OFF and then ON again. Leave the machine for 15 minutes.

This problem may then be cleared.

• The machine may recover from the error, when the test printing of the maintenance mode

for service personnel is started. However, conducting this operation while the heater has

not yet cooled may cause the fuser unit to melt. Be careful.

Step Cause Remedy

1 LED ASSY attachment failure Reattach an LED ASSY.

2

Connection failure of the LED

ASSY flat cable

Reconnect an LED ASSY flat cable.

3

Connection failure of the LED

control flat cable

Reconnect the LED control flat cable.

4 LED ASSY flat cable failure Replace an LED ASSY flat cable.

5 LED control flat cable failure Replace the LED control flat cable.

6 LED control PCB failure Replace the LED control PCB.

7 LED ASSY failure Replace an LED ASSY.

8 Main PCB failure Replace the main PCB.

Loading...

Loading...