17

Installation and wiring

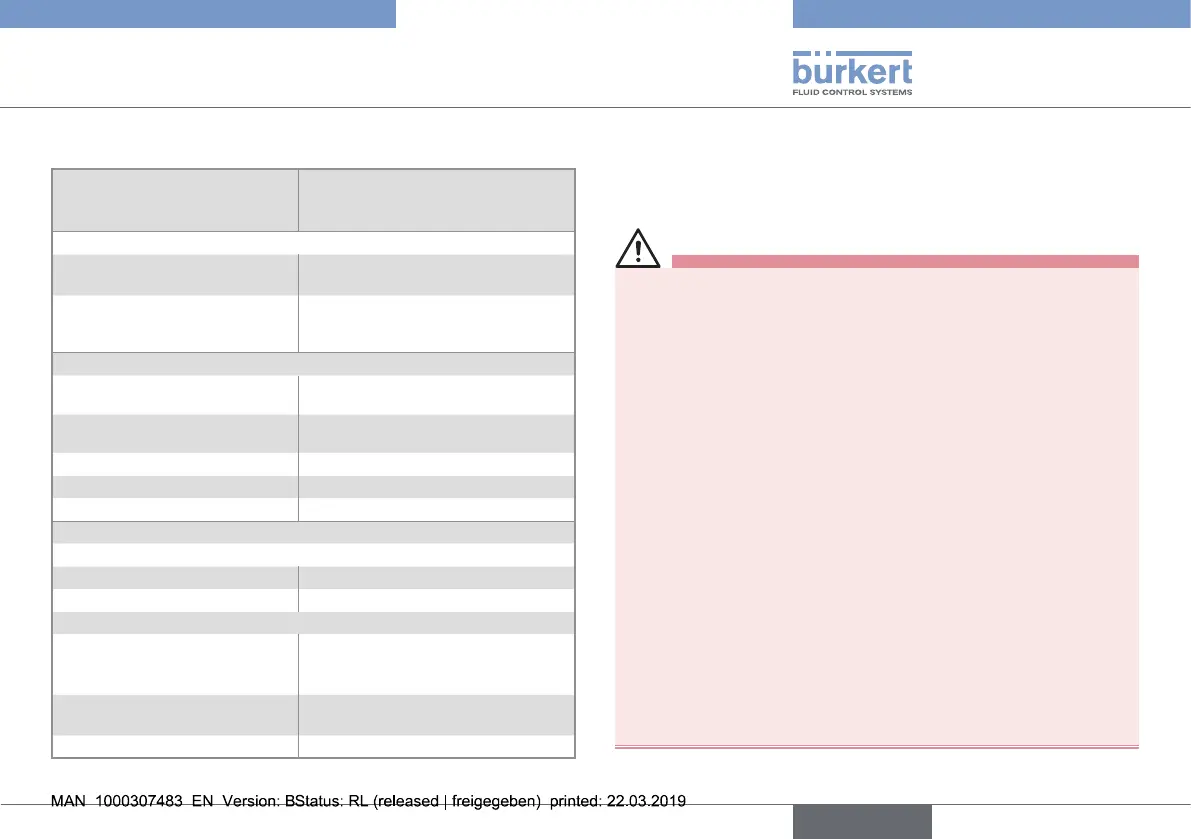

6.3.6. Fluid data

Type of fluid

Refer to the Operating Instruc-

tions of the related sensor-fitting

(S077)

Fluid temperature

• with S077 sensor-fitting in

aluminium

• –20...+80 °C

• with S077 sensor-fitting in

stainless steel

• –20...+120 °C

Max. fluid pressure

• DN15 • 55 bar

1)

(threaded process connection)

• DN25

• 55 bar

1)

(or in accordance to the

value of the used flanges)

• DN40 or DN50

• 18 bar

1)

• DN80

• 12 bar

1)

• DN100

• 10 bar

1)

Flow rate measurement

• Measuring range

- viscosity > 5 mPa.s - 2...1200 l/min

- viscosity < 5 mPa.s - 3...616 l/min

• Measurement deviation

- if "specific" K-factor is

used

(engraved on the

sensor-fitting)

- ±0.5% of the measured

value

- if "standard" K-factor is

used

- ±1% of the measured value

• Repeatability • ±0.03% of the measured value

1)

not evaluated by UL

7. INSTALLATION AND WIRING

7.1. Safety information

Danger

Risk of injury due to high pressure in the installation

▶ Stop the circulation of fluid, cut off the pressure and drain the

pipe before loosening the process connections.

Risk of injury due to high fluid temperatures.

▶ Use safety gloves to handle the device.

▶ Stop the circulation of fluid and drain the pipe before loosening

the process connections.

Risk of injury due to electrical voltage.

▶ If a 12...36 V DC powered version is installed either in a wet

environment or outdoors, all the electrical voltages must be of

max. 35 V DC.

▶ Disconnect the electrical power for all the conductors and iso-

late it before carrying out work on the system.

▶ Do not unscrew the cover of a powered device.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

Risk of injury due to the nature of the fluid.

▶ Respect the prevailing regulations on accident prevention and

safety relating to the use of aggressive fluids.

English

Type 8032 - SE32

Loading...

Loading...