20

Installation and wiring

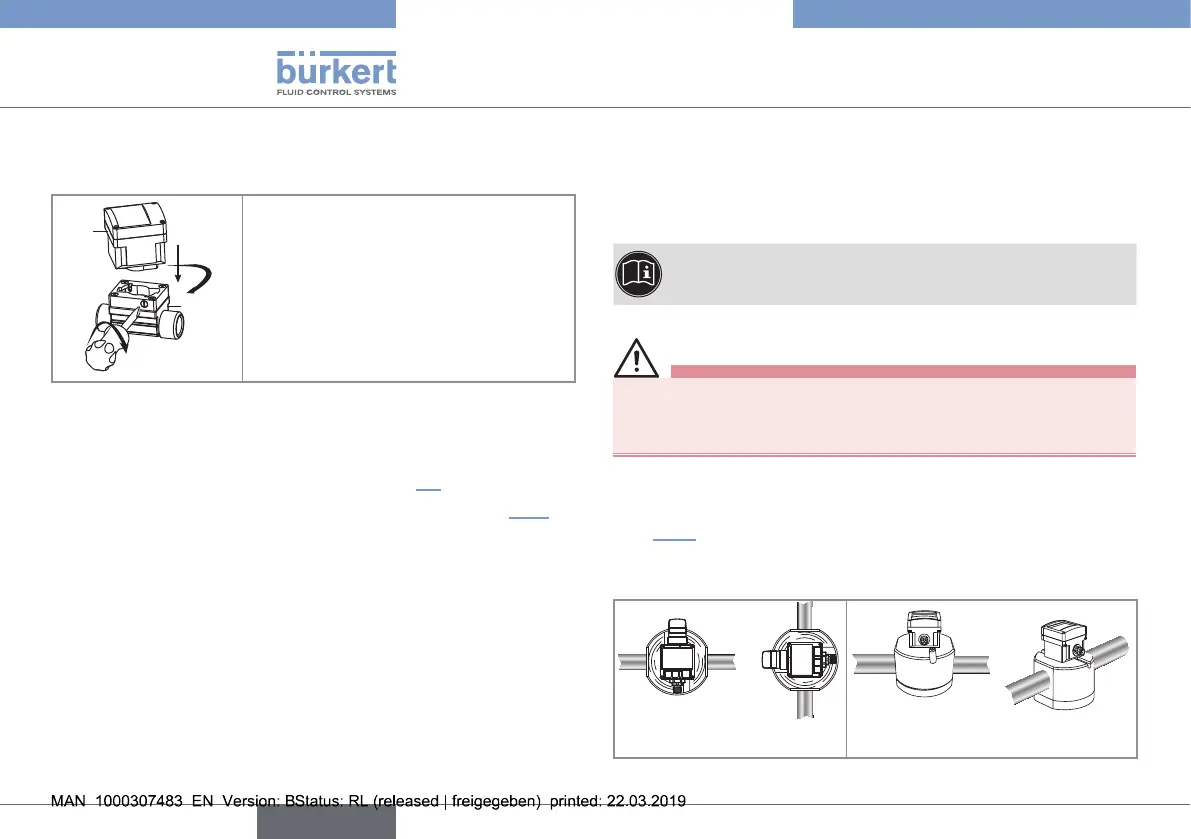

7.2.2. Assemble the SE32 with the S030

sensor-fitting

SE32

S030

1

2

3

→ Install the SE32 in the S030

sensor-fitting.

→ Turn the SE32 by a quarter turn.

→ Tighten the lateral screw(s) to lock

SE32 in place on the sensor-fitting.

(tightening torque max. 1 N·m,

i.e 0.74 lbf·ft).

Fig. 3 : Installation of the SE32 in the S030 sensor-fitting

7.2.3. Finalise the installation of the 8032

→ Wire the device and switch it on (see chap. 7.4).

→ Set the K-factor or determine it with Teach-In (see chap 9.5.2)

7.3. Fluid installation of the SE32 with

an S077 sensor-fitting

The SE32 is inserted into an S077 sensor-fitting mounted on the

pipe. The SE32 is assembled on the S077 sensor-fitting by a

quarter-turn rotation system:

1. Install the S077 sensor-fitting on the pipe,

2. Assemble the SE32 with the S077 sensor-fitting,

3. Finalise the installation.

7.3.1. Install the S077 sensor-fitting on the

pipe

→ Select an S077 sensor-fitting adapted to the viscosity of the

fluid in the pipe.

To select a sensor-fitting, refer to the technical data sheet

for the relevant sensor-fitting.

Caution

Risk of damage when installing the sensor-fitting.

▶ Follow the installation instructions given in the Operating

Instructions for the sensor-fitting.

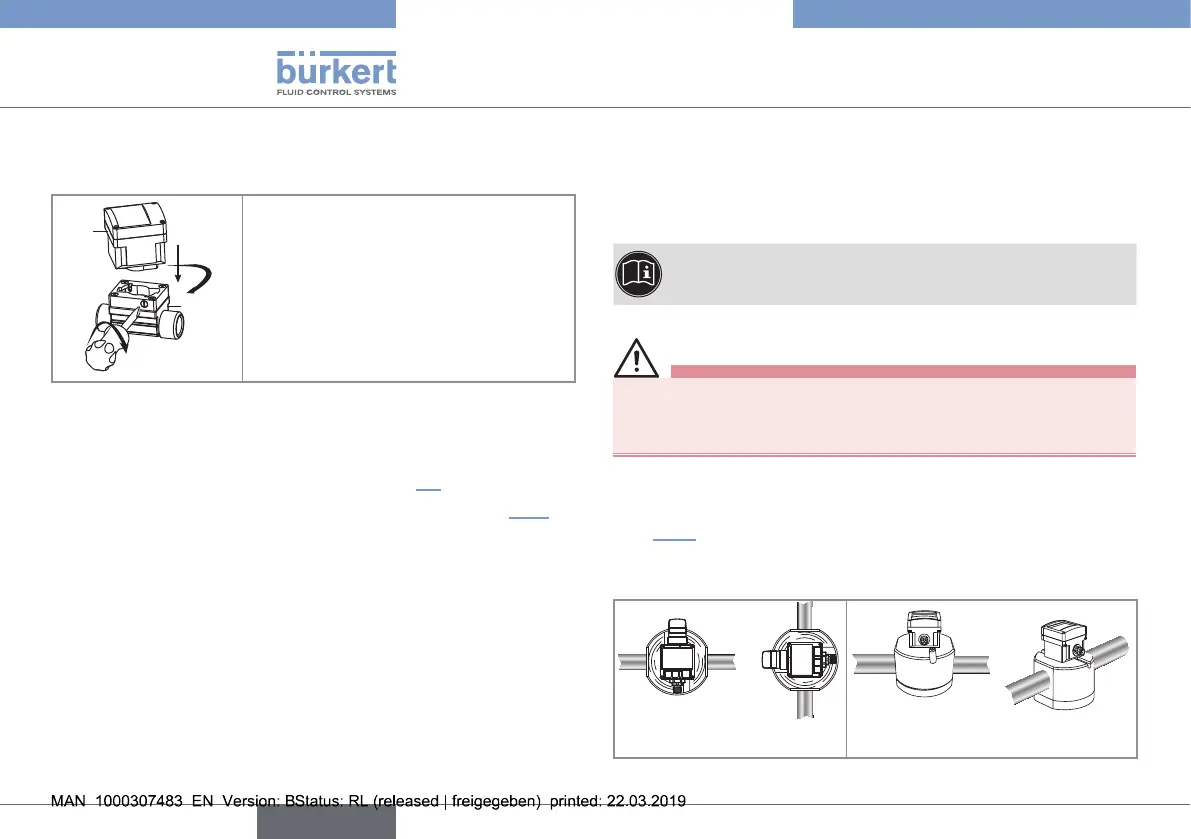

→ Install the sensor-fitting S077 on the pipe in such a way that:

- the spindles of the oval gears are set horizontally, as shown in

Fig. 4.

- the installation instructions given in the Operating Instructions

of the sensor-fitting used are respected.

Correct Incorrect

Fig. 4 : The spindles of the oval gears must be horizontal

English

Type 8032 - SE32

Loading...

Loading...