21

Installation and wiring

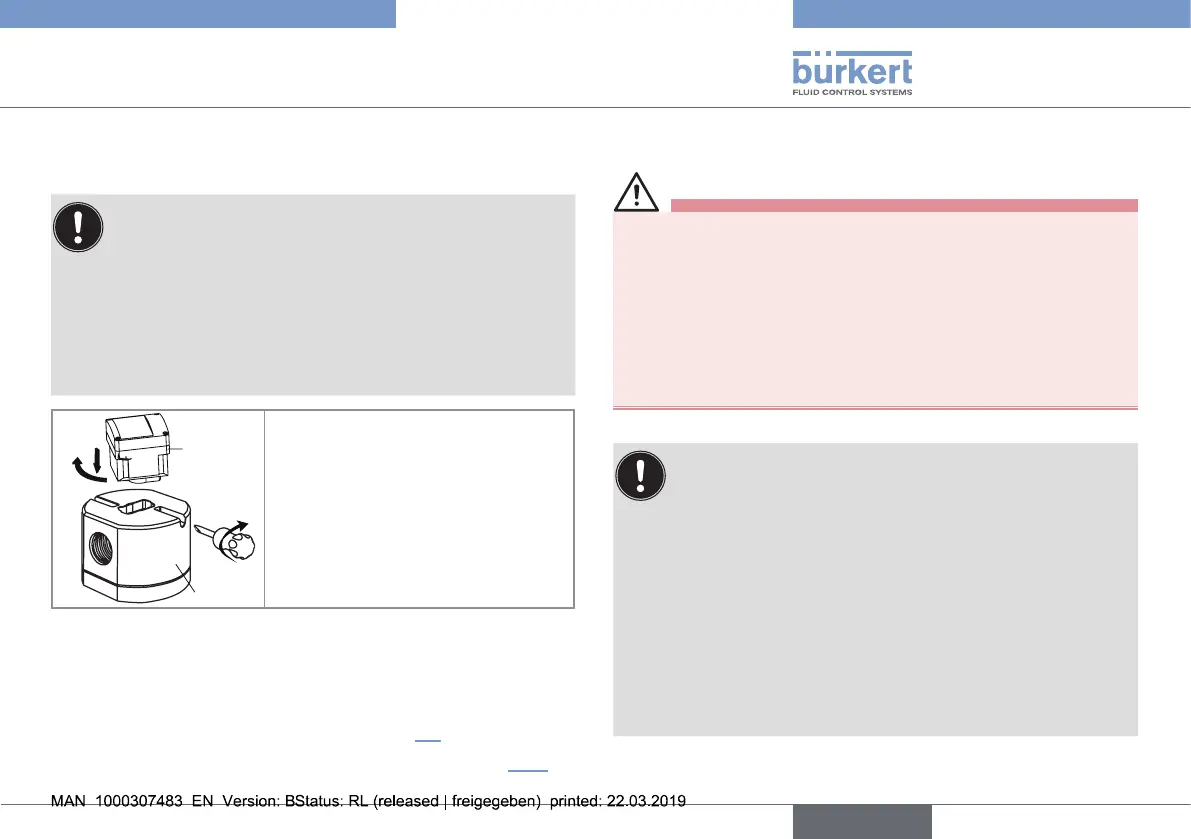

7.3.2. Assemble the SE32 with the S077

sensor-fitting

The SE32 only detects one rotation direction of the oval

gears of a S077 sensor-fitting.

• If the combination SE32 with sensor-fitting S077 does

not run properly, once assembled and energized, do the

following:

→ remove the SE32 from the S077 sensor-fitting,

→ turn the SE32 by 180°,

→ insert the SE32 back into the S077.

SE32

3

2

1

→ Insert the SE32 in the S077

sensor-fitting.

→ Turn the SE32 by a quarter turn.

→ Tighten the lateral screws to lock

the SE32 in place on the S077

sensor-fitting (tightening torque

max. 1 N·m, i.e 0.74 lbf·ft).

Fig. 5 : Installation of the SE32 in the S077 sensor-fitting

7.3.3. Finalise the installation of the SE32

with S077 sensor-fitting

→ Wire the device and switch it on (see chap. 7.4).

→ Set the K-factor or determine it with Teach-In (see chap 9.5.2)

7.4. Wiring

Danger

Risk of injury due to electrical voltage

▶ If a 12...36 V DC powered version is installed either in a wet

environment or outdoors, all the electrical voltages must be of

max. 35 V DC.

▶ Disconnect the electrical power for all the conductors and iso-

late it before carrying out work on the system.

▶ Observe all applicable accident protection and safety regula-

tions for electrical equipment.

• Use shielded cables with a temperature limit of 80°C

minimum.

• Use a high quality electrical power supply, filtered and

regulated.

• Protect the power supply by means of a 1 A fuse and a

switch.

• Protect the power supply of each transistor by means of a

125 mA fuse.

• Protect the relays by means of a max. 3 A fuse and a

circuit breaker (depending on the process).

• Do not apply both a dangerous voltage and a safety extra-

low voltage to the relays.

English

Type 8032 - SE32

Loading...

Loading...