55

Operating and commissioning

Type 8228

The accuracy of the conductivity measurements is influenced by:

• the drift of the zero point of conductivity. Correct the drift of the zero point with the function ZERO CALIB. To

be done if the conductivity of the air measured by the conductivity sensor is higher than 10 µS/cm (see "Cali-

brate the zero point of conductivity (function "Zero Calib." of the menu "Probe")", page 56).

• the conductivity cell constant:

- determine the cell constant of the sensor used with the function CALIBRATION (this calibration updates the

last calibration date in the “Last cal. date” function of the CALIB INTERVAL sub-menu hereafter). See "Cali-

brate the conductivity sensor (“Calibration” function in the “Probe” menu)", page 57,

- or enter the cell constant (marked on the calibration certificate of the device) in the function CELL CON-

STANT. The entering of the cell constant does not update the last calibration date in the “Last cal. date”

function of the CALIB INTERVAL sub-menu. The function CELL CONSTANT makes it also possible to read

the value of the constant which has been determined with the function CALIBRATION.

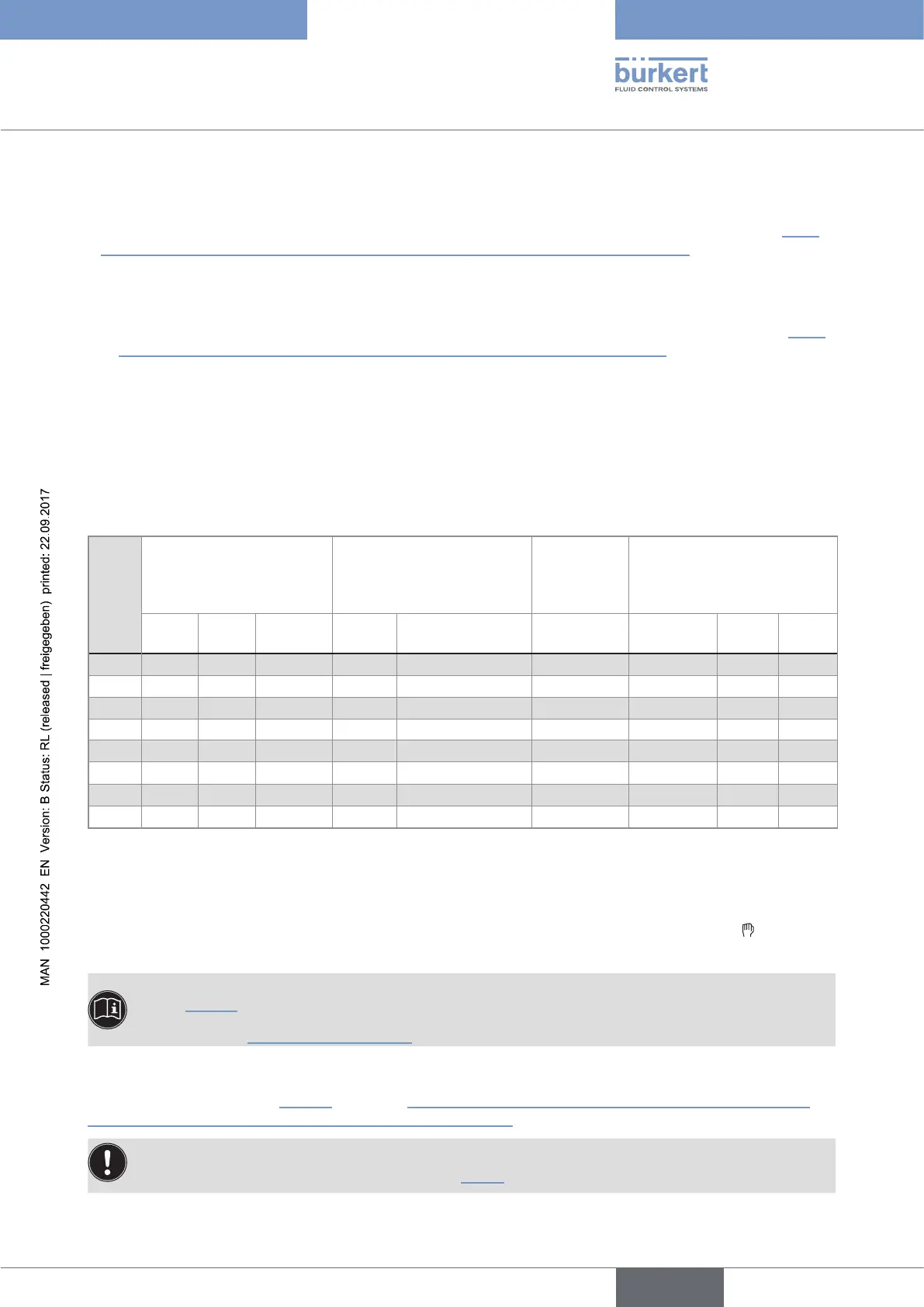

• the correction factor of the fitting. Enter the correction factor related to the fitting S020 used in the function

K-FITTING. The correction factor depends on the shape, the material and the diameter of the fitting used. The

following table gives the correction factors of the fittings S020.

Tab. 1: Correction factors of the fittings S020, depending on the shape, the material and the DN of the fittings

DN

Fittings with true union

connections or fittings with

weld ends

Fittings with internal or

external thread connections

or fittings with weld end

connections

Measurement

chamber Welding sockets or fusion

spigots

PVDF PP PVC Brass Stainless steel

Stainless

steel

PVDF PP

<32 1,08 1,08 1,08 0,99 0,99 - - - -

32 1,08 1,08 1,08 0,99 0,99 0,99 - - -

40 1,04 1,04 1,04 0,99 0,99 0,99 - - -

50 1,02 1,02 1,02 0,99 0,99 0,99 0,99 - -

65 - - - - - - 0,99 1,02 1,02

80 - - - - - - 0,99 1,02 1,02

100 - - - - - - 1,00 1,02 1,02

>100 - - - - - - 1,00 1,00 1,00

CELL CST TDS: enter the TDS factor suited to your process. The TDS factor allows for calculating the amount

of Total Dissolved Solids (TDS), in ppm, depending on the measured conductivity. The default TDS factor is 0,46

(NaCl)

CALIB INTERVAL: read the date of the last calibration (function “Last cal. date”) and set the periodicity of cali-

brations, in days (function “Interval”): the device generates a “maintenance” event by displaying the

icon and a

“warning” message, each time a calibration is due. Set function “Interval” to “0000 days” to ignore the function.

• The "warning" message may be associated with one or other or both transistor outputs (see

chap. 9.11.10).

• See also chap. "10.3 Solving a problem".

TEACH SPECIAL: define the temperature compensation curve specific to your process. The curve thus deter-

mined and memorised is used by the device when you choose “Special” in the “Comp.” function in the menu

“Param - Sensor” (see chap. 9.11.11). See also "Define the temperature compensation curve specific to your

process (“Teach special” function in the”Probe” menu)", page 59.

The compensation curve determined with the function TEACH SPECIAL cannot be transferred to another

device with the function DOWNLOAD (see chap. 9.11.1).

English

Loading...

Loading...