PRE-INSTALLATION

Inspection —

Inspect the unit; file a claim with the ship-

ping company if the unit is damaged. Check the packing list

to ensure that the correct items have been received and no-

tify your Carrier representative of any discrepancy.

Rigging and Handling — To transfer the unit from

the shipping platform to the storage or installation site, refer

to the rigging label on the unit and these instructions. (See

Tables 13-15 for motor, component, and coil weights.)

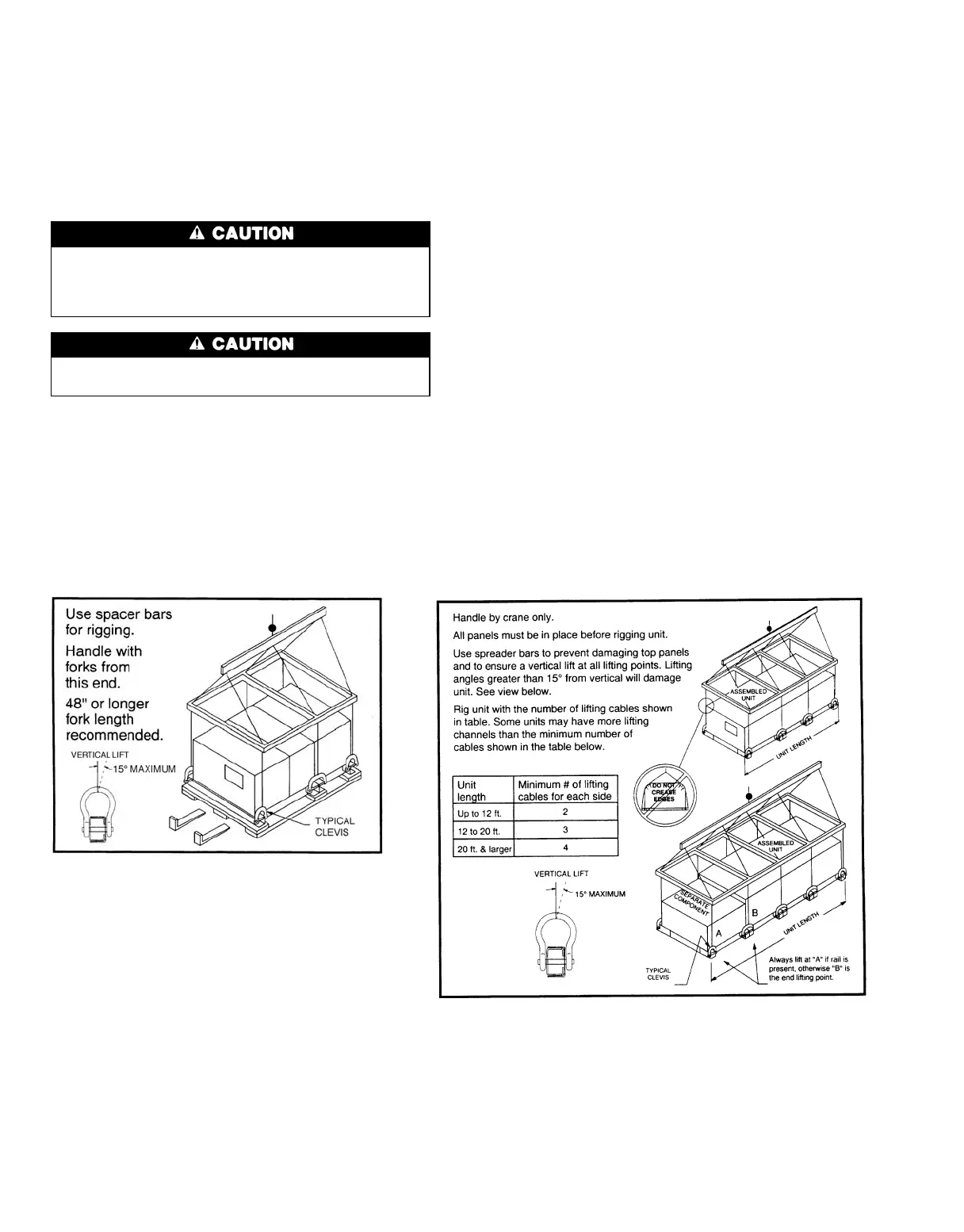

You can use a forklift truck to move units or compo-

nents only if they have full skids. Lift from the heavy

end of the skid. Minimum recommended fork length is

48 in., as shown in Fig. 8.

Do not stack unit components or accessories during stor-

age. Stacking can cause deformation or damage.

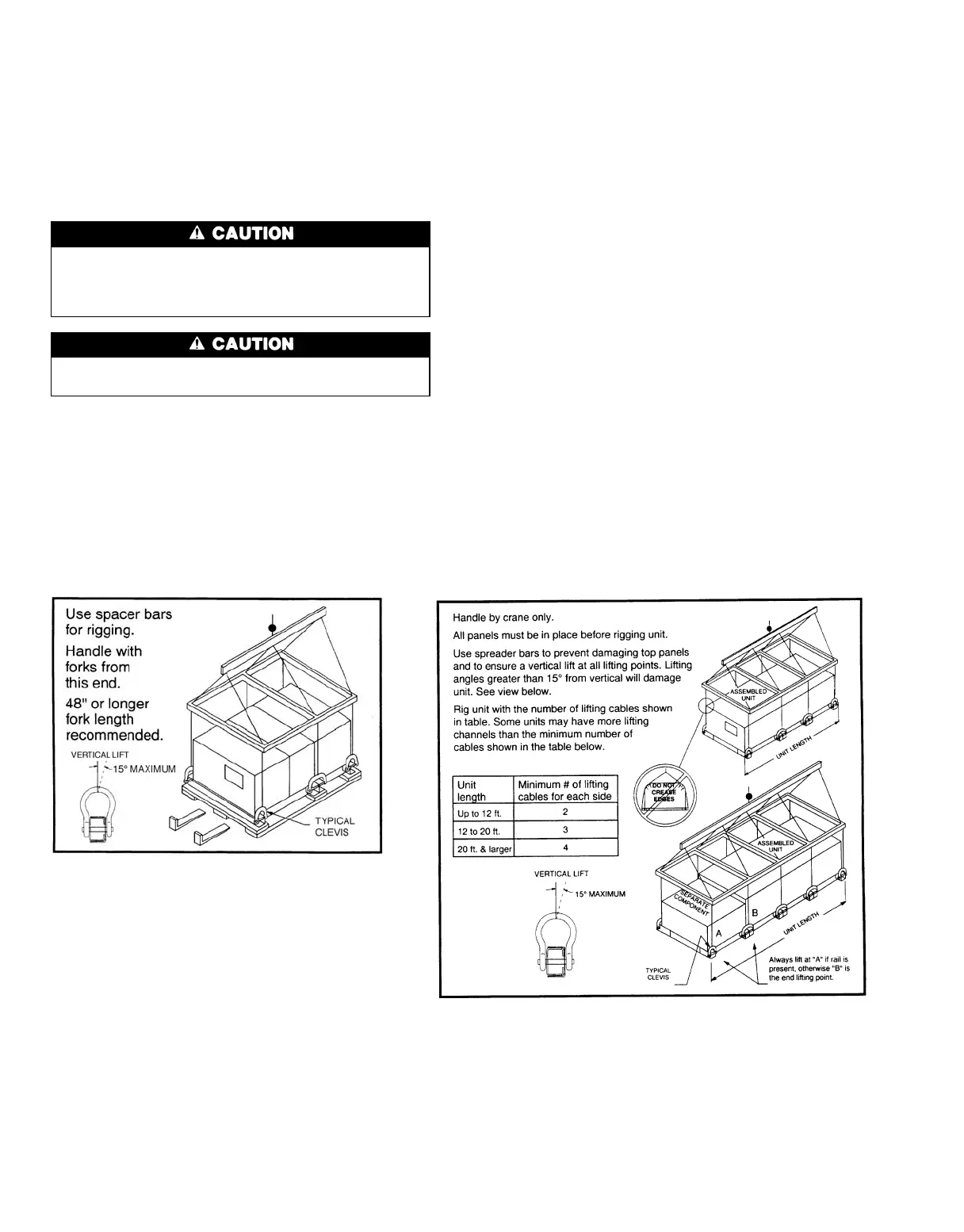

Base units are shipped fully assembled, except when sec-

tions are separately ordered or when the unit height exceeds

108 inches. All 39T units can be rigged using the lifting brack-

ets, as shown in Fig. 8.

Connection flanges are provided at every section; to sepa-

rate components at the connection flanges:

1. Remove all fasteners on vertical and horizontal (side and

top) seams.

2. Remove the large through-bolts in lifting brackets and smaller

bolts that hold lifting brackets to the base rail. See Fig. 9.

3. Lift the unit with slings and header bars, using clevises

and pins in the large oval holes in the unit’s lifting

brackets.

When the unit is in its final location, do not remove the

caps from the coil connections until the coil is ready for pip-

ing. Do not remove grease from the fan shaft until the drive

sheave is ready for installation.

During installation, insulation and bottom panels can be

protected by placing a temporary rigid walkway (such as ply-

wood) inside the unit.

Long-Term Storage — If storing the unit before in-

stallation, observe the following precautions:

1. The storage site should be level, rigid, and free of debris.

If the site is in a heavy rain area, set the unit off of the

ground.

2. Do not store the unit in a heavy traffic area or on a

vibrating surface. Vibration can damage stationary

bearings.

3. Ensure that all coil connections have shipping caps in place.

Cover the entire unit with a waterproof tarpaulin or plas-

tic coverall; if the unit is stored on the ground, extend the

cover underneath the unit. Secure the cover with tiedowns

if the unit is outdoors. Do not remove the cover or coil

connection caps until you install the unit.

4. Monthly — Move the coverall, enter the fan section through

the access door or fan inlet, and slowly rotate the fan and

motor by hand. This operation prevents bearing corro-

sion by redistributing the bearing grease.

Fig. 8 — Rigging Labels

UNITS WITH SKIDS

UNITS WITHOUT SKIDS

22

Loading...

Loading...