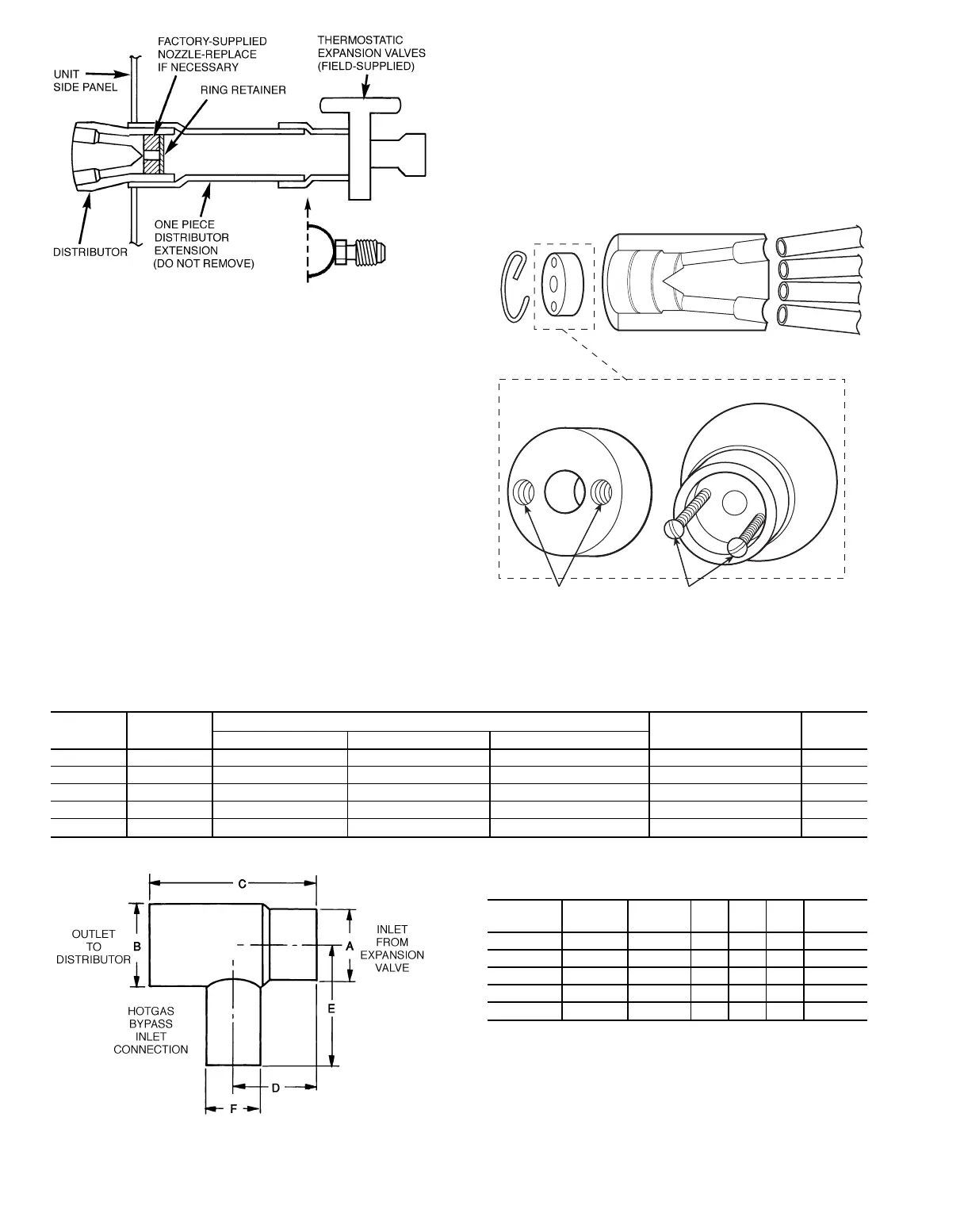

HOT GAS BYPASS — When low-load operation requires

use of hot gas bypass, hot gas must be introduced between

expansion valve and distributor.

Install auxiliary hot gas bypass side connector (field-

supplied) in coil split that is first on, last off.

NOTE: See Table 21 for auxiliary side connector sizes. Do

not attempt to use a valve that is smaller or larger than dis-

tributor size. Inserting a bushing at the outlet will defeat the

purpose of the internal nozzle tube extension.

Install the side connector as follows:

1. Remove distributor nozzle and retainer ring (area A) from

distributor and reinstall in inlet (area B) of side connec-

tor. See Fig. 49.

2. Solder field-supplied extension nipple to coupling on dis-

tributor, then to side connector outlet, using a silver

solder or equivalent with a melting point of 1300 to

1500 F. Extension nipple should be as short as possible.

3. Solder expansion valve outlet to side connector using

95-5 tin-antimony soft solder, for easy removal.

4. If required, install field-supplied adapter bushing or

coupling to connector inlet before soldering to expansion

valve outlet.

Table 21 — Auxiliary Side Connector (Hot Gas Bypass) Data

SPORLAN

TYPE

CARRIER

PART NO.

CONNECTION SIZES (in.)

USED WITH SPORLAN

DISTRIBUTOR TYPE

NOZZLE

SIZE

Inlet — ODM Solder Outlet — ODF Solder Auxiliary — ODF Solder

ASC-5-4 —

5

⁄

8

5

⁄

8

1

⁄

2

1620, 1622 J

ASC-7-4 EA19BA504

7

⁄

8

7

⁄

8

1

⁄

2

1112, 1113 G

ASC-9-5 EA19BA705 1

1

⁄

8

1

1

⁄

8

5

⁄

8

1115, 1116 E

ASC-11-7 EA19BA905 1

3

⁄

8

1

3

⁄

8

7

⁄

8

1117, 1126 C

ASC-13-9 — 1

5

⁄

8

1

5

⁄

8

1

1

⁄

8

1125, 1127, 1143 A

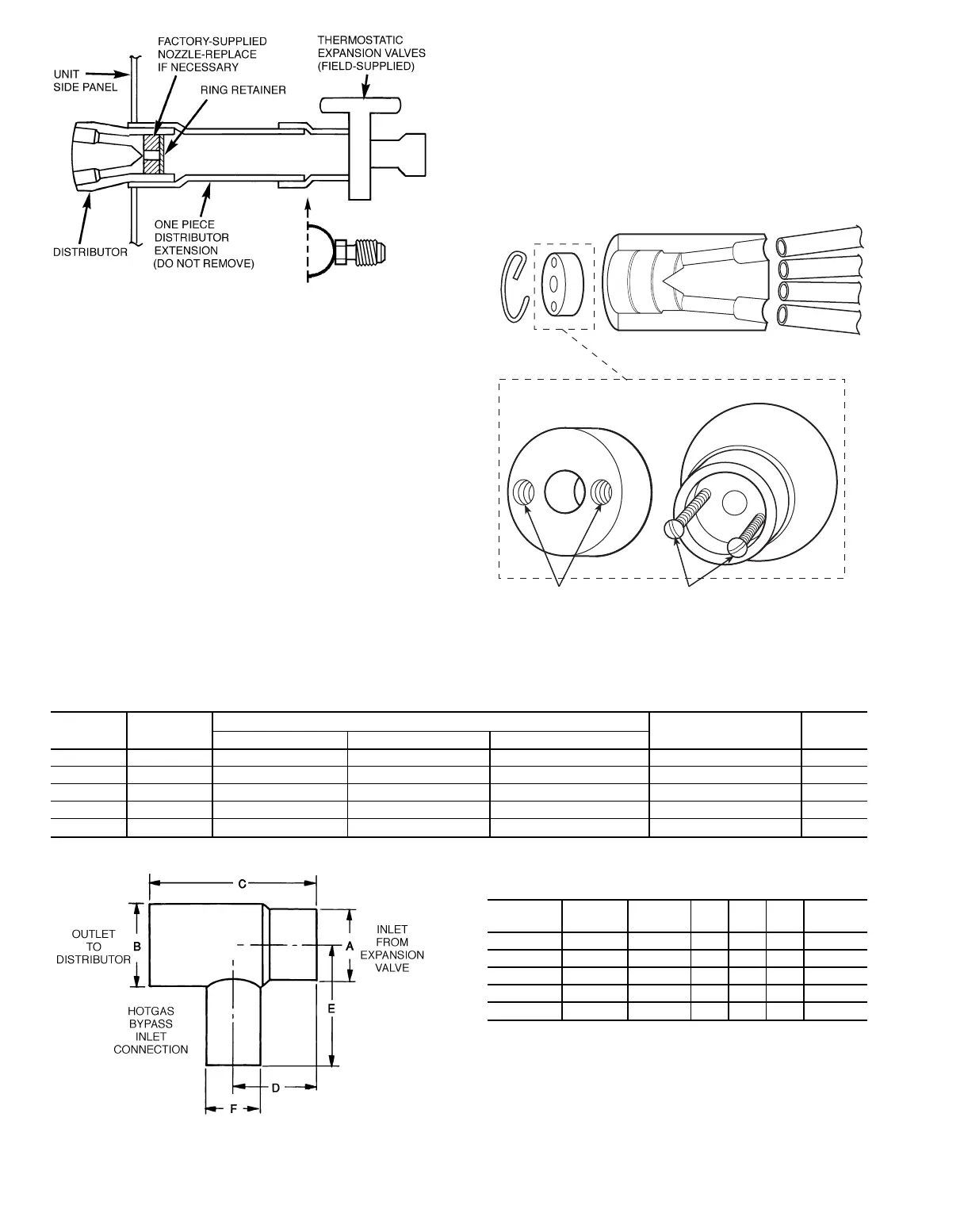

DIMENSIONS (in.)

SPORLAN

TYPE

ABCDEF

ASC-5-4

5

⁄

8

ODM

5

⁄

8

ODF 1.88 0.95 1.25

1

⁄

2

ODF

ASC-7-4

7

⁄

8

ODM

7

⁄

8

ODF 2.25 1.06 1.38

1

⁄

2

ODF

ASC-9-5 1

1

⁄

8

ODM 1

1

⁄

8

ODF 2.81 1.47 1.62

5

⁄

8

ODF

ASC-11-7 1

3

⁄

8

ODM 1

3

⁄

8

ODF 3.53 1.89 2.19

7

⁄

8

ODF

ASC-13-9 1

5

⁄

8

ODM 1

5

⁄

8

ODF 3.72 1.83 2.75 1

1

⁄

8

ODF

LEGEND

ODF — Outside Diameter, Female

ODM — Outside Diameter, Male

Fig. 47 — Expansion Valve Piping

RETAINER

RING

NOZZLE

BODY TUBING

SIMPLIFIED NOZZLE

REMOVAL

G

5

NO. 6-32 THREADED

PULLER HOLES

THREADED

PULLER RODS

Fig. 48 — Nozzle Change-Out

60

Loading...

Loading...