Inlet Guide Vane Actuators, Airfoil Fans — Inlet

guide vanes are available as options on airfoil fans. They

must be adjusted in the field as follows.

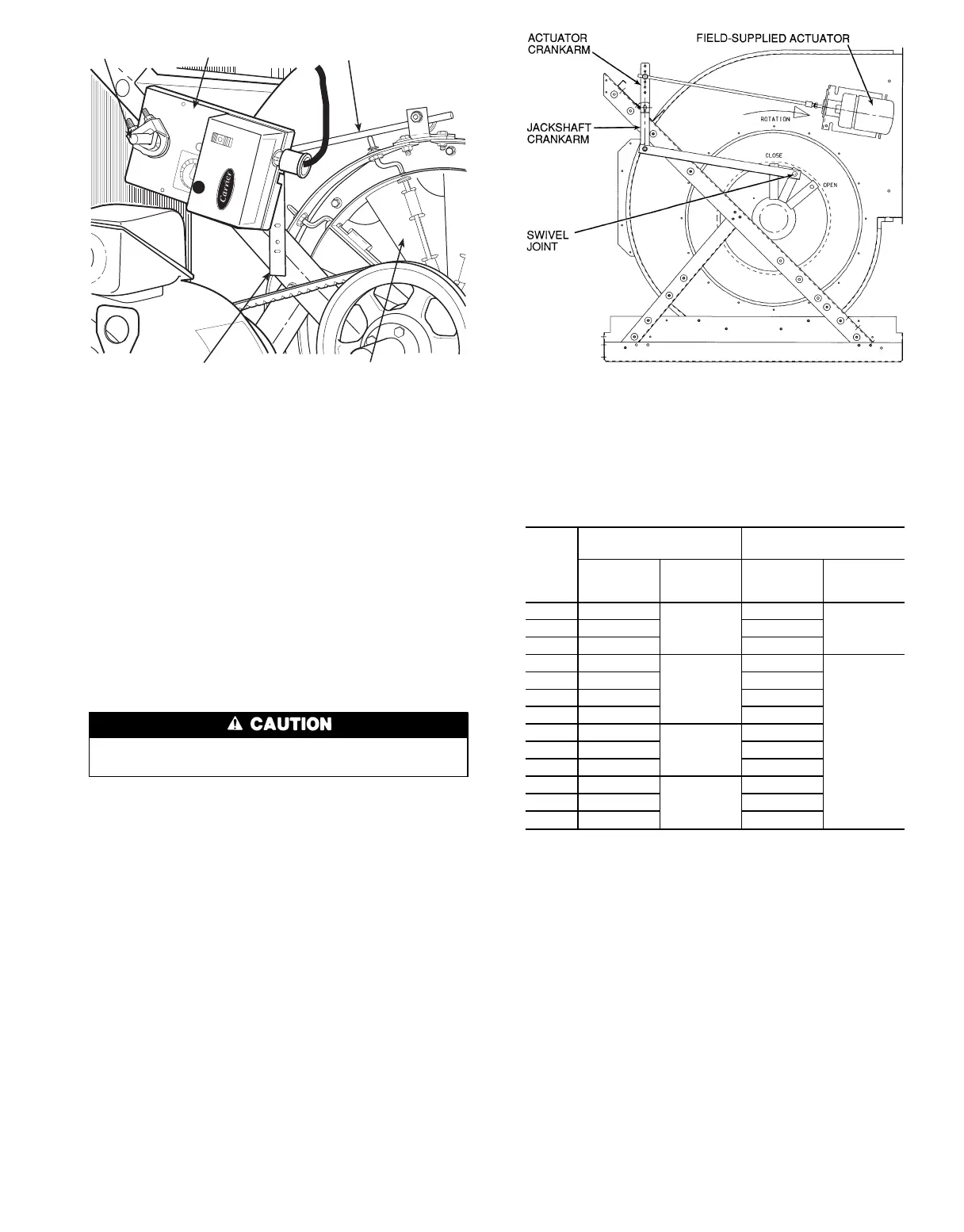

POSITION ACTUATOR — The interconnecting linkage

between the two vane assemblies is factory supplied. The

actuator and mounting brackets are field-supplied. Mount

the actuator to the scroll A-frame or side plate as shown in

Fig. 32.

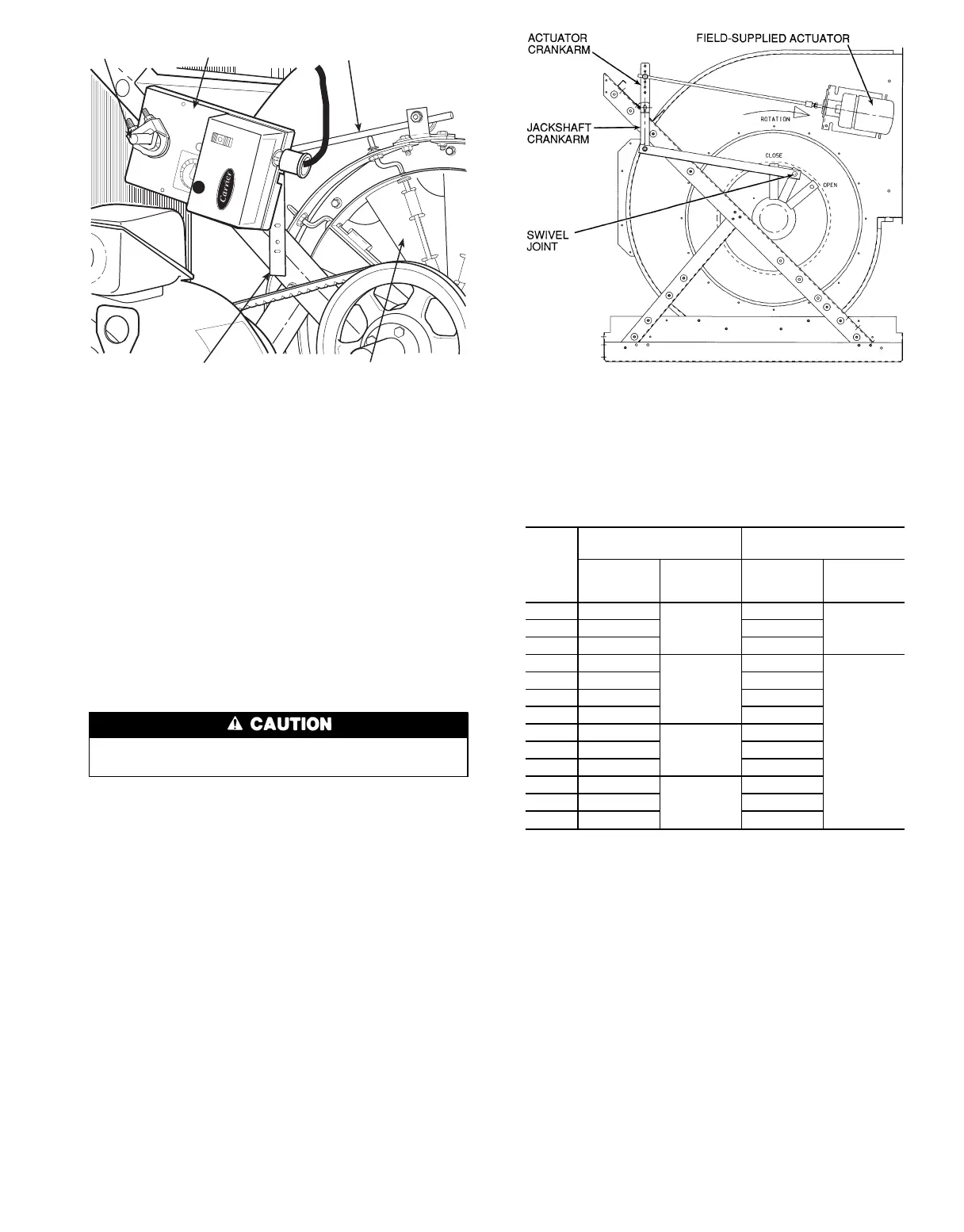

CHECK LINKAGE — Linkage adjustment holes are pro-

vided in the actuator crankarm; adjust the actuator and link-

age for the proper jackshaft rotation listed in Table 16. After

the linkage travel and jackshaft rotation are set, verify that

both vane assemblies move together from the fully open to

fully closed positions.

Do not force inlet guide vanes past the fully open or

fully closed positions.

Figure 32 shows a top horizontal front discharge. With

the vanes closed, the swivel joint is at the 12 o’clock posi-

tion. With the swivel joint at the same 12 o’clock position,

other discharge arrangements (upblast or downblast) should

have fully open vanes. Regardless of the swivel joint posi-

tion, the jackshaft crankarm and swivel on the left and right

vane assemblies must be in line with each other for correct

operation.

Table 16 — Inlet Guide Vane

Actuator Requirements

39T

UNIT

SIZE

AIRFOIL FANS

FORWARD-CURVED

FANS

Jackshaft

Torque

(in.-lbs)

Jackshaft

Rotation

(Degrees)

Jackshaft

Torque

(in.-lbs)

Jackshaft

Rotation

(Degrees)

07 143

45

78

7509 182 93

11 238 93

13 195

60

104

80

17 208 150

21 310 166

26 370 185

32 359

67

185

39 435 203

49 600 222

61 487

100

265

74 579 —

92 579 —

IGV

ACTUATOR

CONNECTING

ROD

ANTI-ROTATION

STRAP

INLET GUIDE

VANES (IGV)

IGV

JACKSHAFT

Fig. 31 — IGV Actuator Mounting

NOTE: When the unit is not operating, vanes may not fully close. This

condition is normal. During unit operation, airflow and pressure

differential help to control and close the vanes.

Fig. 32 — Inlet Guide Vane Linkage Adjustment —

Airfoil Fan

41

Loading...

Loading...