4

This system is cooled by means of the forced circulation of air,

and must therefore be placed in such a way that the air may

be easily sucked in and expelled through the apertures made

in the frame.

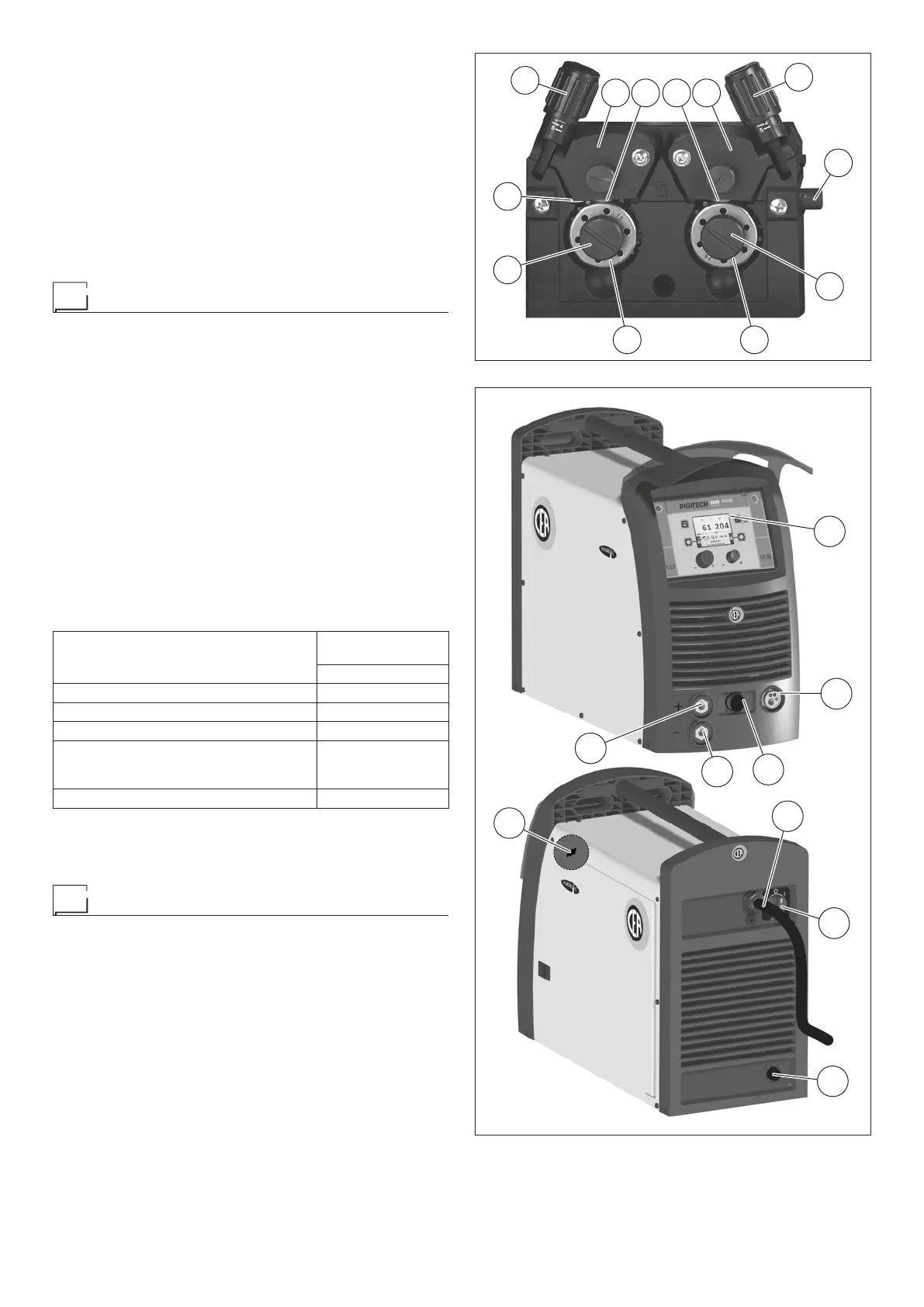

Assemble the system in the following way:

• Assemble the trolley.

• Fixing the cooling unit to the trolley.

•

Fixing of the welding machine to the trolley and the cooling

unit (electrical and plumbing connections).

• Connect up the welder to the mains.

•

Connect up the wire-feeder/generator interconnection cable.

• Connect up the welding cables.

Instructions for fitting the individual components / optional ex-

tras are contained in the relevant packaging.

Connection to the electrical supply

Connection of the machine to the user line (electrical cur-

rent) must be performed by qualified personnel.

Before connecting the welding machine to the mains pow-

er supply, make sure that rated voltage and frequency cor-

respond to those provided by the mains power supply and

that the welding machine’s power switch is turned to “O”.

Use the welder’s own plug to connect it up to the main pow-

er supply. Proceed as follows if you have to replace the plug:

•

3 conducting wires are needed for connecting the machine

to the supply.

•

The fourth, which is YELLOW GREEN in colour is used for

making the “GROUND” connection.

Before connecting the welding machine to the mains pow-

er supply, make sure that rated voltage and frequency cor-

respond to those provided by the mains power supply and

that the welding machine’s power switch is turned to “O”.

Table 2 shows the capacity values that are recommended for

fuses in the line with delays.

Table 2

Model

DIGITECH vision

PULSE 3200

MIG-MAG welding

Input power @ I

2

Max kVA 18,8

Delayed fuse (I

2

@ 60%) A 25

Duty cycle @ 40% (40°C) A 320

Mains cable

Length

Section

m

mm

2

4

4 × 2,5

Ground cable mm

2

50

NOTE: Any extensions to the power cable must be of a suita-

ble diameter, and absolutely not of a smaller diameter than the

special cable supplied with the machine.

Loading wire

•

Fit the reel (diam. 300 mm) on the support so that the wire

unrolls clockwise, and center the projecting reference on the

support with the relative hold on the reel.

•

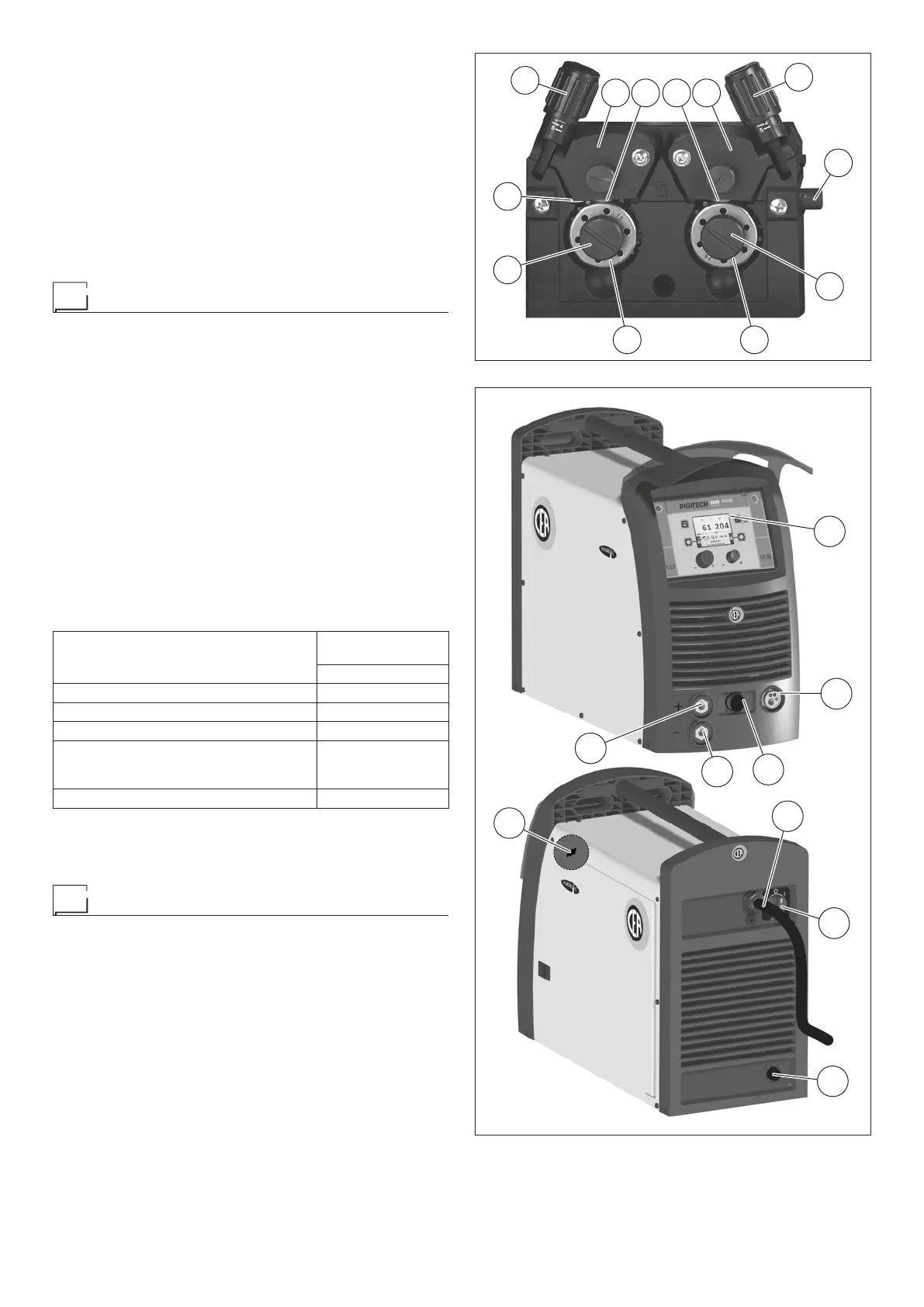

Thread the end of the wire into the back guide (Pos. 1, Fig. A)

on the drawing mechanism.

•

Lift up the idle rolls (Pos. 4, Fig. A) releasing the roll pres-

sure device (Pos. 2, Fig. A). Make sure that the drive rolls

(Pos. 7, Fig. A) have the diameter corresponding to the wire

being used stamped on the outside.

• Insert the wire into the central wire guide and the wire guide

on the centralised connection (Pos. 5, Fig. A) by a few cen-

timetres. Lower the idle roller holder arms, making sure that

the wire slots into the hollow in the motor’s roller. If neces-

sary, adjust the pressure between the rollers by turning the

6

5

2

3 4 4 3

2

1

6

FIG. A

6

1

5

4

9

7

8

2

3

FIG. B

Loading...

Loading...