55

EQUIPMENT LAYOUT ADVANCED SETUP Menu

The purpose of this menu is to allow the operator to manage connections of components and accessories that are part of the

welding plant.

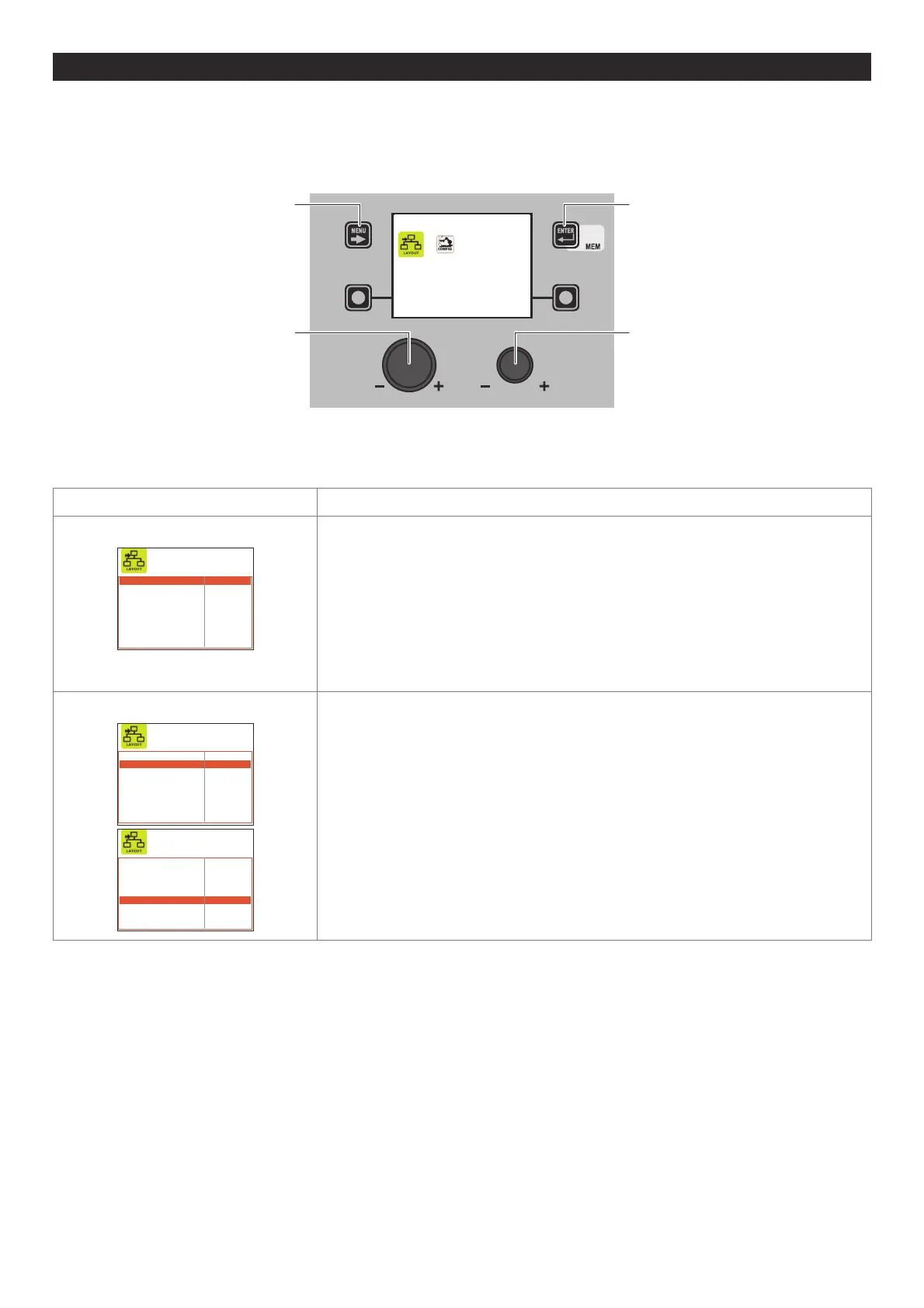

To access the EQUIPMENT LAYOUT Menu from the SETUP Menu:

• Turn the ENCODER K

NOB - SX to select the desired icon.

• Push the ENTER/MEM K

EY.

MENU KEY ENTER/MEM KEY

ENCODER KNOB - SX ENCODER KNOB - DX

EQ. LAYOUT

Within the EQUIPMENT LAYOUT Menu, it is possible, by rotating the ENCODER KNOB - SX, to select the component of the welding

plant, while by rotating the ENCODER K

NOB - DX, you can decide the type of connection required (e.g. Optional) or the type of com-

ponent (e.g. Torch 400 A H2O) that is to be connected to the plant (this operation does not require confirmation).

Advanced function Description

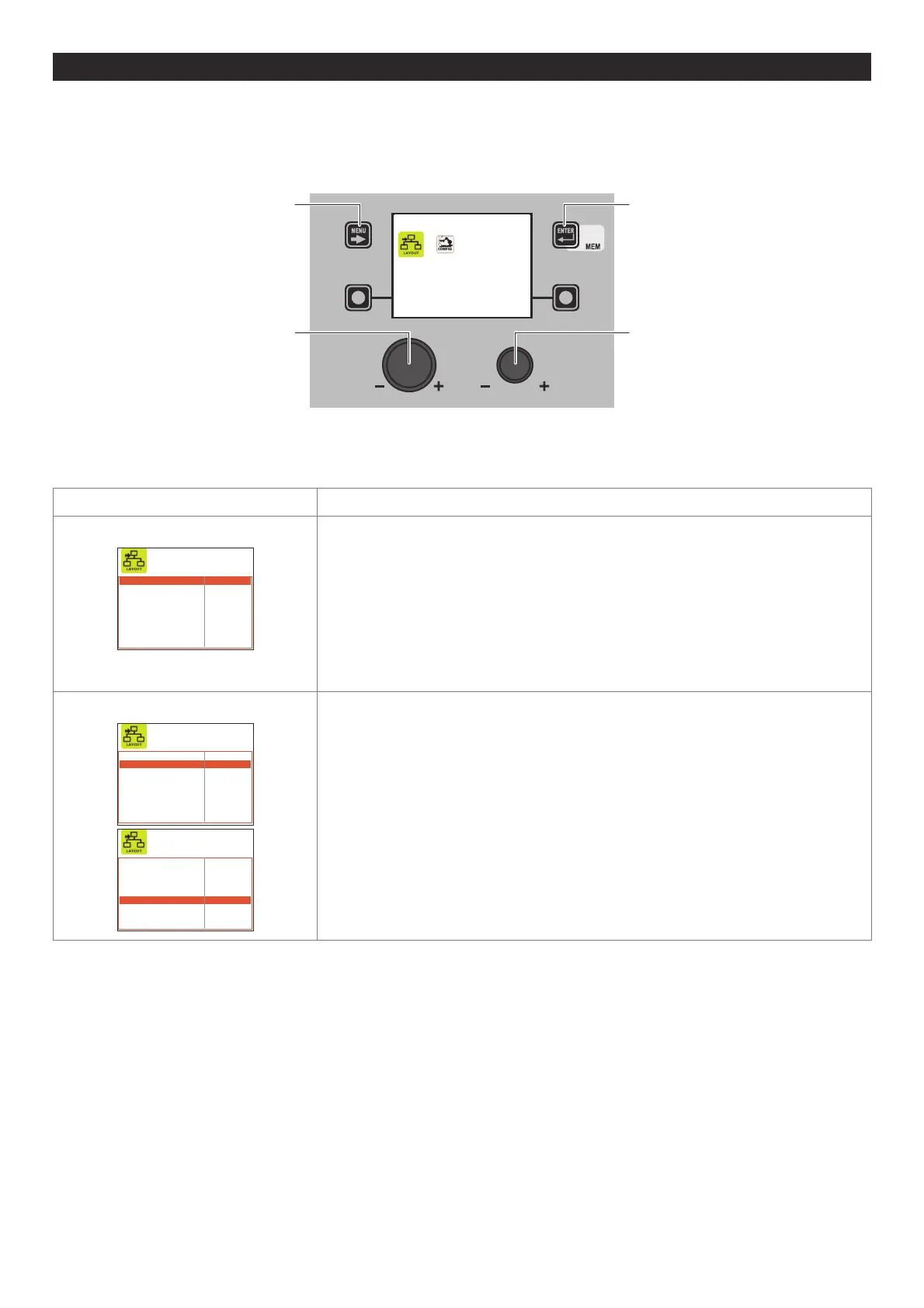

WATER COOLER

WATER COOLER OPTIONAL

WIRE FEEDER 1 OPTIONAL

REMOTE CONTROL 1 RC OPTIONAL

TORCH TYPE 1 400A H2O

SAFETY CALIBRATION CODE 1 013

WIRE FEEDER 2 ABSENT

REMOTE CONTROL 2 RC OPTIONAL

TORCH TYPE 2 400A H2O

SAFETY CALIBRATION CODE 2 013

OPTIONAL - Means that the water cooler system may or may not be connected to the

welding machine.

OBLIGATORY - Means that it is obligatory for the water cooler system to be connected to

the welding plant.

A error condition is generated when:

• Switching on or at any other time if the welding plant does not detect the presence.

• During normal operation if the water cooler system is disconnected.

Also see the CONFIG menu if it is necessary to keep the cooling system working

continuously.

WIRE FEEDER 1 / WIRE FEEDER 2

WATER COOLER OPTIONAL

WIRE FEEDER 1 OPTIONAL

REMOTE CONTROL 1 RC OPTIONAL

TORCH TYPE 1 400A H2O

SAFETY CALIBRATION CODE 1 013

WIRE FEEDER 2 ABSENT

REMOTE CONTROL 2 RC OPTIONAL

TORCH TYPE 2 400A H2O

SAFETY CALIBRATION CODE 2 013

WATER COOLER OPTIONAL

WIRE FEEDER 1 OPTIONAL

REMOTE CONTROL 1 RC OPTIONAL

TORCH TYPE 1 400A H2O

SAFETY CALIBRATION CODE 1 013

WIRE FEEDER 2 ABSENT

REMOTE CONTROL 2 RC OPTIONAL

TORCH TYPE 2 400A H2O

SAFETY CALIBRATION CODE 2 013

OPTIONAL - This means that FEEDER 1-2 can or cannot be connected to the welding

plant. Once feeder 1-2 is detected when the plant is switched on, its presence becomes

obligatory.

OBLIGATORY - This means that it is obligatory for FEEDER 1-2 to be connected to the

welding plant, even when the plant is switched on.

A error condition is generated when:

• When switched on, if the welding plant does not detect its presence.

• During normal operation if the wire feeder is disconnected.

MISSING - Means that feeder 2 must not be managed by the plant, even if it is

connected up.

NOTE: If the second feeder is not connected up, all the settings relate to feeder 1.

NOTE: The FEEDER 2 section must also be set to allow feeder 2 to work in a robotised

plant.

(continued)

Loading...

Loading...