– Steamhosesmustbepreventedfromsagging(condensatepockets);ifnecessary,supportwithpipe

clamps,trough,orwallbrackets,orinstallacondensatedraininthesteamhose.

– Important! When deciding on the length and layout of the hose, it should be noted that the steam

hosemaybecomesomewhatshorterwithprogressiveageing.

Securing the hose

Thesteamhosemustbesecuredtothesteamdistributionpipeandhumidiersteamoutletbymeans

of hose clamps.

Steam line with xed piping

Forsteamlineswithxedpiping,thesameinstructionsapplytothelayingofthepipingasalready

described.Thefollowingadditionalnotesshouldbeobserved:

– The minimum internal diameter of 42 mmshouldbeappliedoverthewholelengthofthepip-

ing.

– UseexclusivelyCupipe(operationwithuntreateddrinkingwater)orstainlesssteel(min.DIN1.4301,

operationwithfullydemineralizedwater).

– Tominimizethecondensateformation(=loss),thesteampipesmustbeinsulated.

– The minimum bend radius for rigid piping is 100 mm.

– Connectionofthesteampipestothesteamdistributionpipeandsteamhumidieriseffectedby

meansofshortlengthsofsteamhosesecuredwithhoseclamps.Connectiontothesteamhumidi-

erissecuredviaaG11/4”coupling.

– Important! Allowancemustbemadeforapressure loss of 10 mm water column (approx. 100 Pa)

per meter line length or per 90° angle.

5.3.4 Installing the condensate hose

Important!UseoriginalCondaircondensatehoseexclusively.Othertypesofhosescancauseopera-

tional malfunctions.

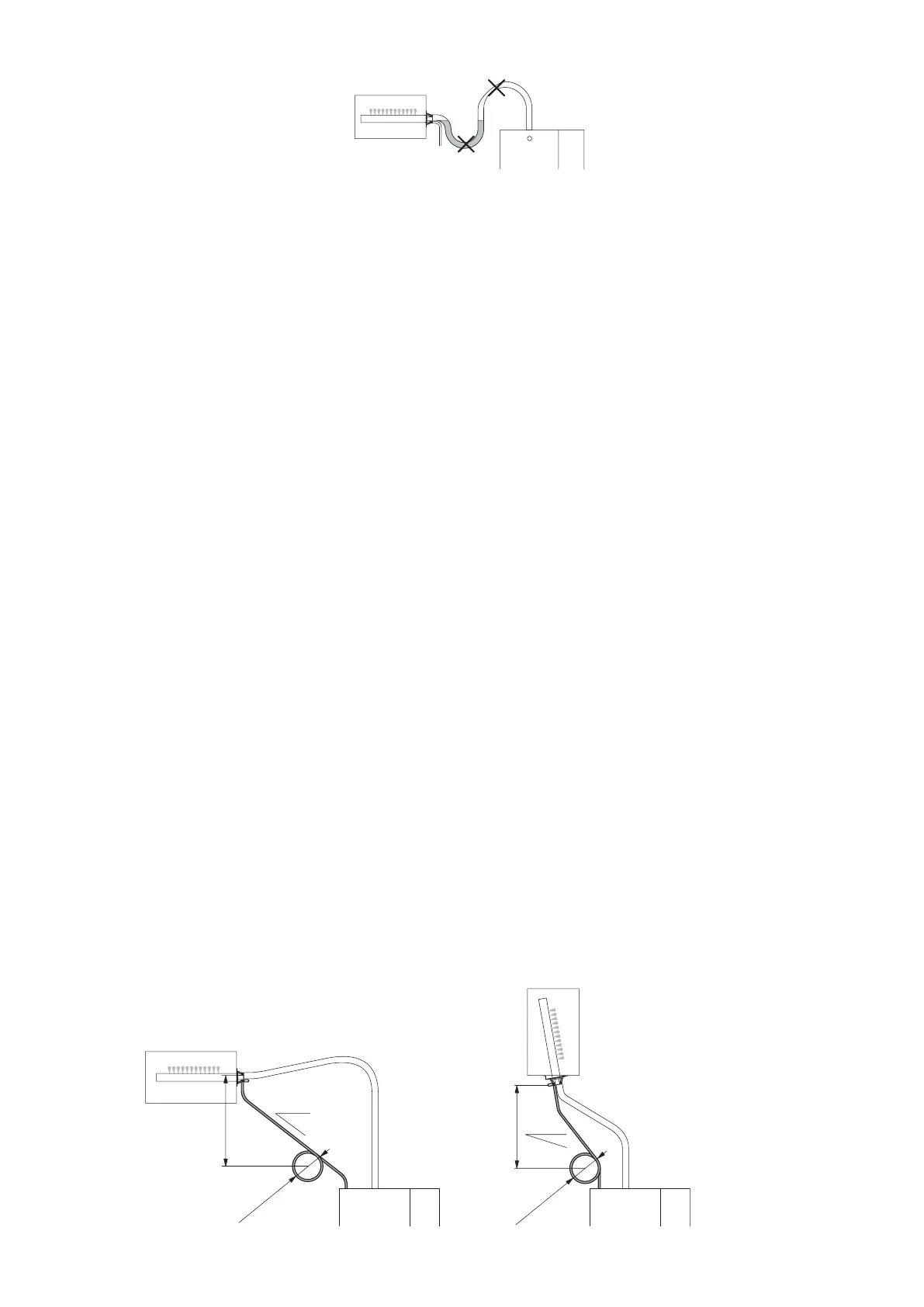

The hose layout depends on the position of the steam distribution pipe:

– Steam distribution pipe is mounted more than 300 mm above the top edge of the humidier:

Condensatehoseisleddowntothehumidierwithaminimum slope of 20 %, in the form of a

siphon (min. hose bend radius Ø200 mm ),andinsertedabout2cmintothespeciedopening.

min. 300 mm

min. 20 %

Ømin. 200 mm

min. 300 mm

min. 20 %

Ømin. 200 mm

Loading...

Loading...