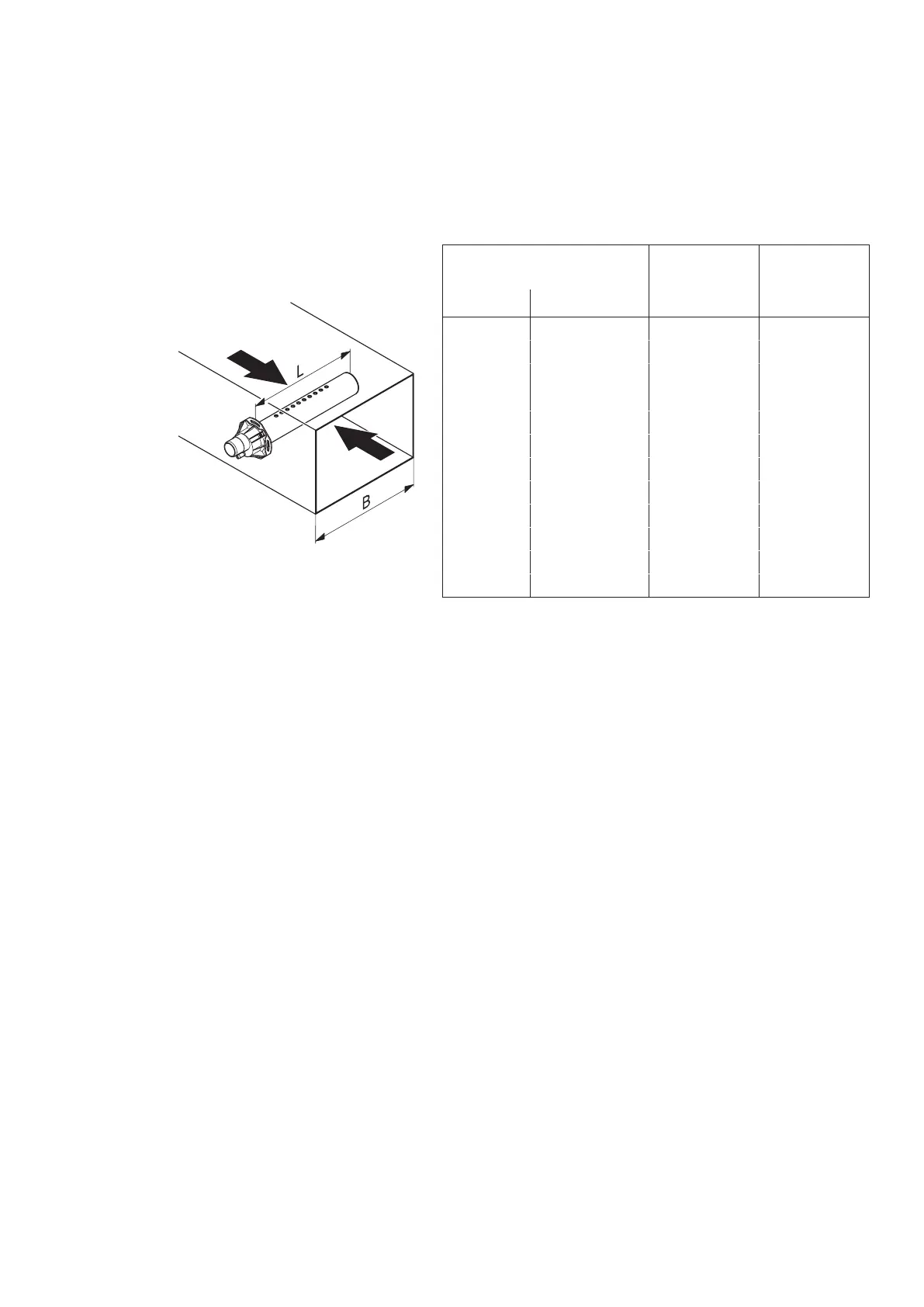

Steam distribution pipes 81-... for indirect room humidication

The steam distribution pipes are selected on the basis of the duct width(forhorizontalinstallation)or

the duct height(forverticalinstallation)andthecapacityofthesteamhumidier.

Important!Always select the longest possible steam distribution pipe(optimum humidication dis-

tance).

4.4.2 Accessory details

Steam distribution pipes 81-...

for Condair Mk5 (CrNi steel)

Duct width (B) Steam output

Type Length in mm (L)

3)

in mm max. in kg/h

81-200

1)

200 210...400 10

81-350

2)

350 400...600 30

81-500

2)

500 600...750 30

81-650

650 750...900 50

81-800

800 900...1100 50

81-1000

1000 1100...1300 50

81-1200

1200 1300...1600 50

81-1500

1500 1600...2000 50

81-1800

1800 2000...2400 50

81-2000

2000 2200...2600 50

81-2300

2300 2500...2900 50

81-2500

2500 2700...3100 50

1)

Onlyforunitswithamax.steamcapacityof10kg/h

2)

Onlyforunitswithamax.steamcapacityof30kg/h

3)

Special length available on request

Note:Ifthehumidicationdistance(seechapter5.3.1)hastobereducedfortechnicalreasons,the

amountofsteamperbasicunitmustbedividedbetweentwosteamdistributionpipesorthe OptiSorp

steam distribution system must be used. If this is the case, contact your supplier.

Steam distribution pipe “Process” (accessory “Z...”)

The steam distribution pipe “Process” is used for direct humidication of material in manufacturing

processes (process humidication), or inventilation ducts with a critical saturation distance (the

steamdistributionpipe“Process”reducesthesaturationdistancebyapproximately30%).Thedesired

lengthmustbespeciedwhenordering.

Pleasecontactyoursupplier,theywillassistyouincustomizingthesteamdistributionhead“Process”.

Pleasehavethefollowinginformationreadilyavailable:

– steamquantityinkg/h

– dimensionsofventilationduct(widthxheight)

Important! Thetableforthedeterminationofthehumidicationdistanceprovidedinchapter5.3.1does

not apply to the Process steam distribution pipe.

Loading...

Loading...