Chapter II – System Operation

2-1

C

996-0255 rev. b

Chapter II System Operation

The System Operation section contains the steps for running the laser on

a daily basis. For more detailed operations such as alignment or changing

flashlamps, see the Troubleshooting and Maintenance sections.

A. Startup procedure

1) Open city water and drain source connected to laser

system.

2) Switch on electronics rack circuit breaker located on front

upper right hand side of cabinet. The CG604C pump will

also turn on.

3) Switch ON the 24V power supply switch located on rear

of electronics cabinet. See drawing on page 3-15.

4) Turn key on front panel of CU601C counter-clockwise to

the ON position.

5) After approximately 15 seconds the control unit CU601C

will complete its system check and countdown. The

phrase MANUAL MODE is then displayed on the

remote box RB601.

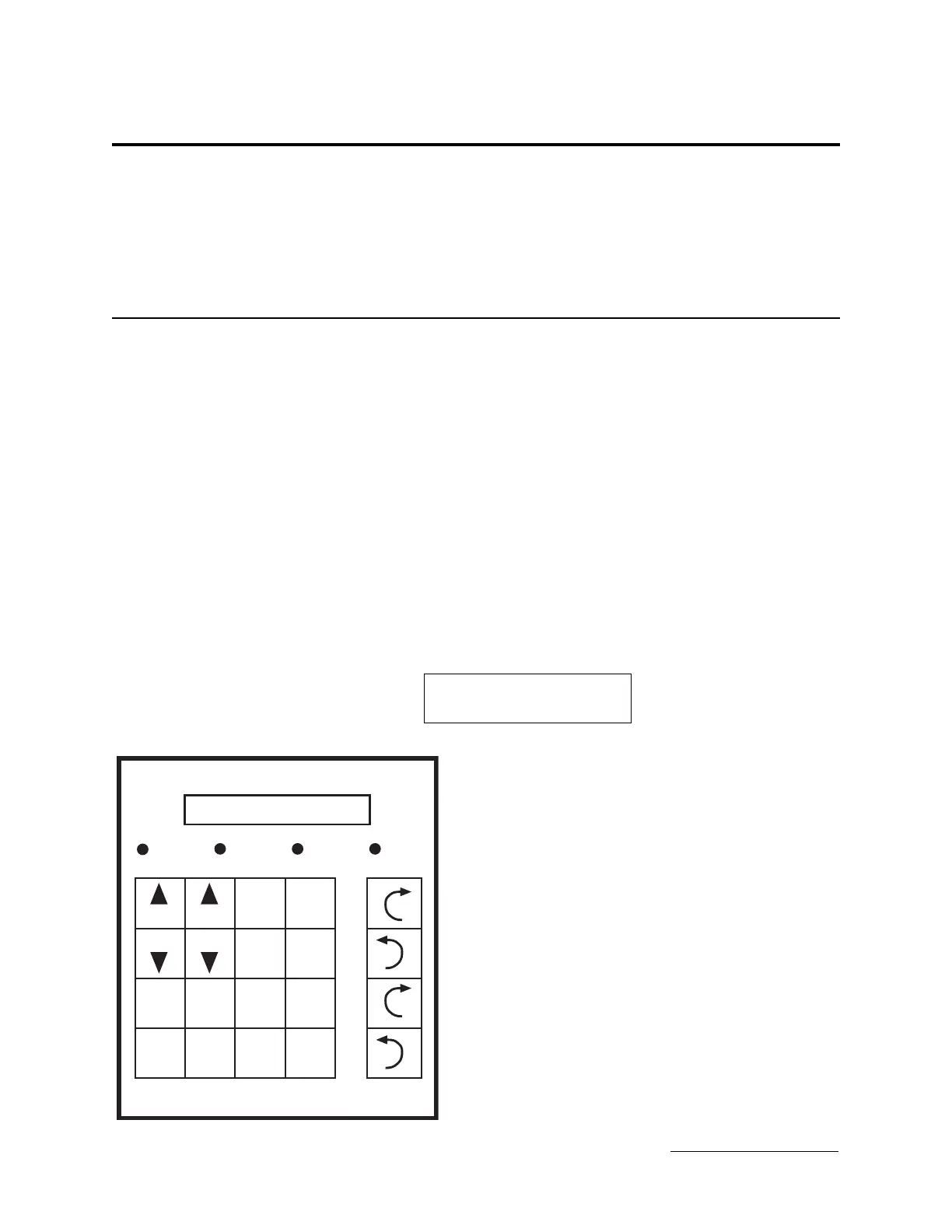

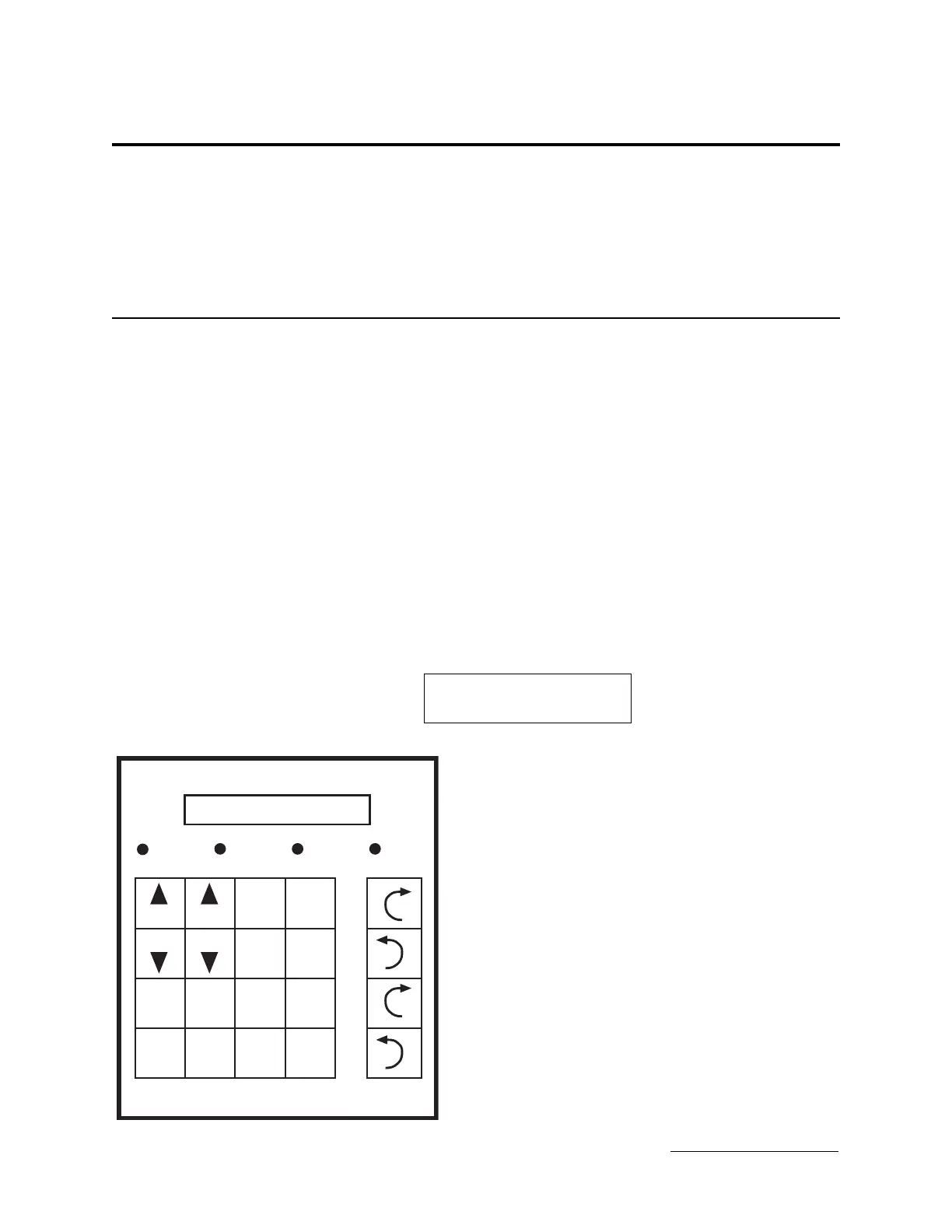

6) Press the AUTO/MANUAL key on

the RB601 and then press the START key.

7) The system will cycle to programmed

mode #1 (PGM1) for system warm-up.

The laser heads should now be flashing at

the standard rep rate.

8) For lasers with the SI-500 option

(Seeded SLM), turn the key switch to the

ON position (on the seed laser’s control

panel on the side of the laser head) and

the shutter switch to the CLOSED posi-

tion.

9) Allow the system to run for 30 minutes

without Q-switching to thermally stabi-

lize the system.

charging end of

charge

shutter

open

Q-sw.

active

1

1

2

2

program

program

parameter

parameter

shutter

remote/

local

store parameter

select

charge start

activate reset fire stop

Q-sw.

on/off

auto/

manual

harmonic

generator

RB601 keyboard

Continuum

MANUAL MODE

SHOT COUNT XXXXXXX

Loading...

Loading...