10/2007 - Art. Nr. 13 017 700B12

Start-up

Description and settings

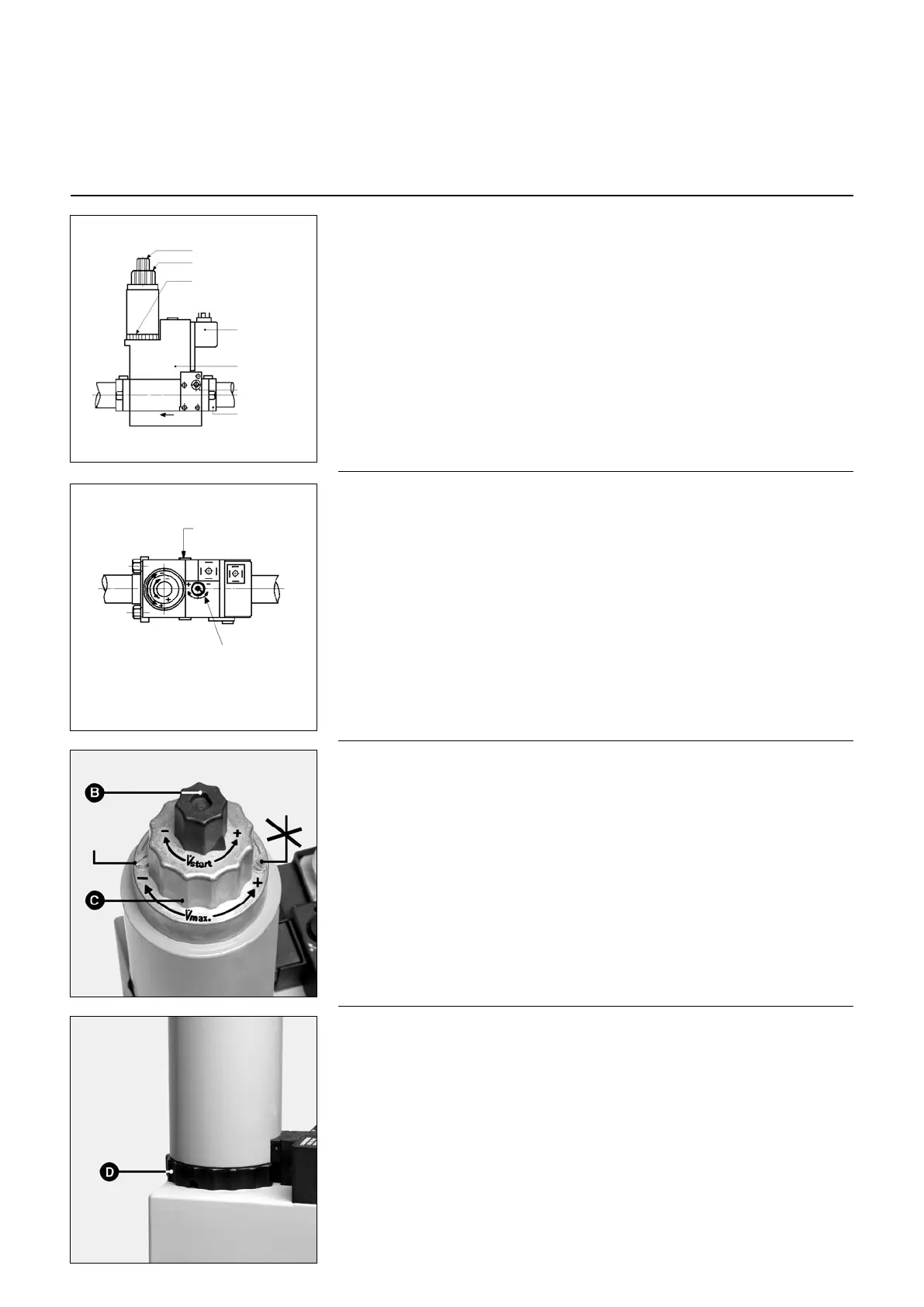

2-stage gas valve

2-stage gas valve

MB ZRDLE...B01S..

Compact assembly consisting of a filter,

an adjustable air pressure switch, a non

adjustable, quick acting safety valve, an

adjustable pressure controller, two

valves 1

st

and 2

d

stage of which the flow

stage is incrementally adjustable on

opening.

Upon delivery:

- The valve is preset for the power

values shown in the table

- The progressive rate is set to a

two-turn opening

- The stage two valve is open to its

maximum extent.

- The pressure switch is set to minimum.

General setting procedure

The setting for stage two is only carried

out by actuating the pressure controller:

the stage two valve (button C) is open to

its maximum extent.

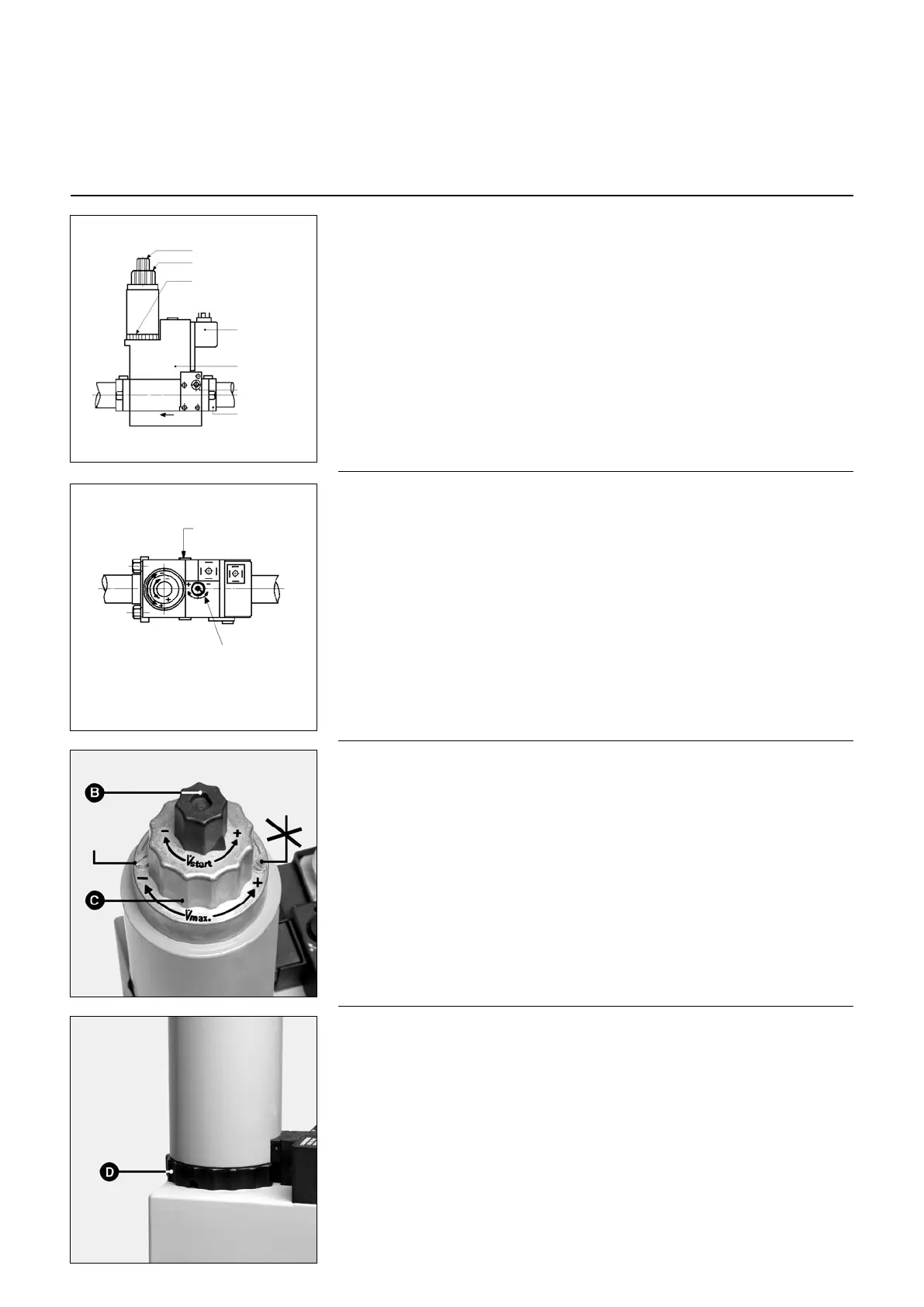

The progressive rate upon ignition and

changing from one stage to another is

set by actuating button B.

The setting for stage one is carried out

by actuating crown D.

Controller setting:

Controller pressure measurements are

carried out at pBr.

The pressure setting provides the

desired flow rate.

Setting the progressive rate:

This hydraulic brake function acts on the

ignition flow rate and the shift between

stages.

• Unscrew plastic stopper B.

• Turn it around and use it as a spanner.

The setting has a 3-turn stroke.

• Rotate it in the direction of the:

- arrow: the progressive rate will

increase

+ arrow: the progressive rate will

decrease.

Particular case

Nominal flow stage setting

This is necessary only if the flow stage

read under a pressure of 4 mbar on the

controller is too high.

Do as follows:

• loosen the locking screw avoiding to

touch the opposite painted screw.

Plug C has a 4.5-turn travel length.

• Make the screw rotate in a cw direction

arrow -. The flow stage decreases

and vice versa.

It might be necessary to adjust the

pressure.

• Tighten the locking screw.

Incremental advance setting

Main flow stage

setting

Setting 1

st

stage

Pressure switch

Coil

Access to filter

Connecting

flange

pBr

Pressure

controller

setting

S 20 = 4 to 20 mbar

S 50 = 4 to 50 mbar

Locking

screw

Painted

screw

Setting the stage one flow rate

• Unscrew the locking screw without

touching the painted screw opposite.

• Rotate crown D clockwise by hand

(without using a tool): the flow rate will

decrease and vice versa.

• Tighten the locking screw back up.

Loading...

Loading...