10/2007 - Art. Nr. 13 017 700B 19

Maintenance

Checking combustion components

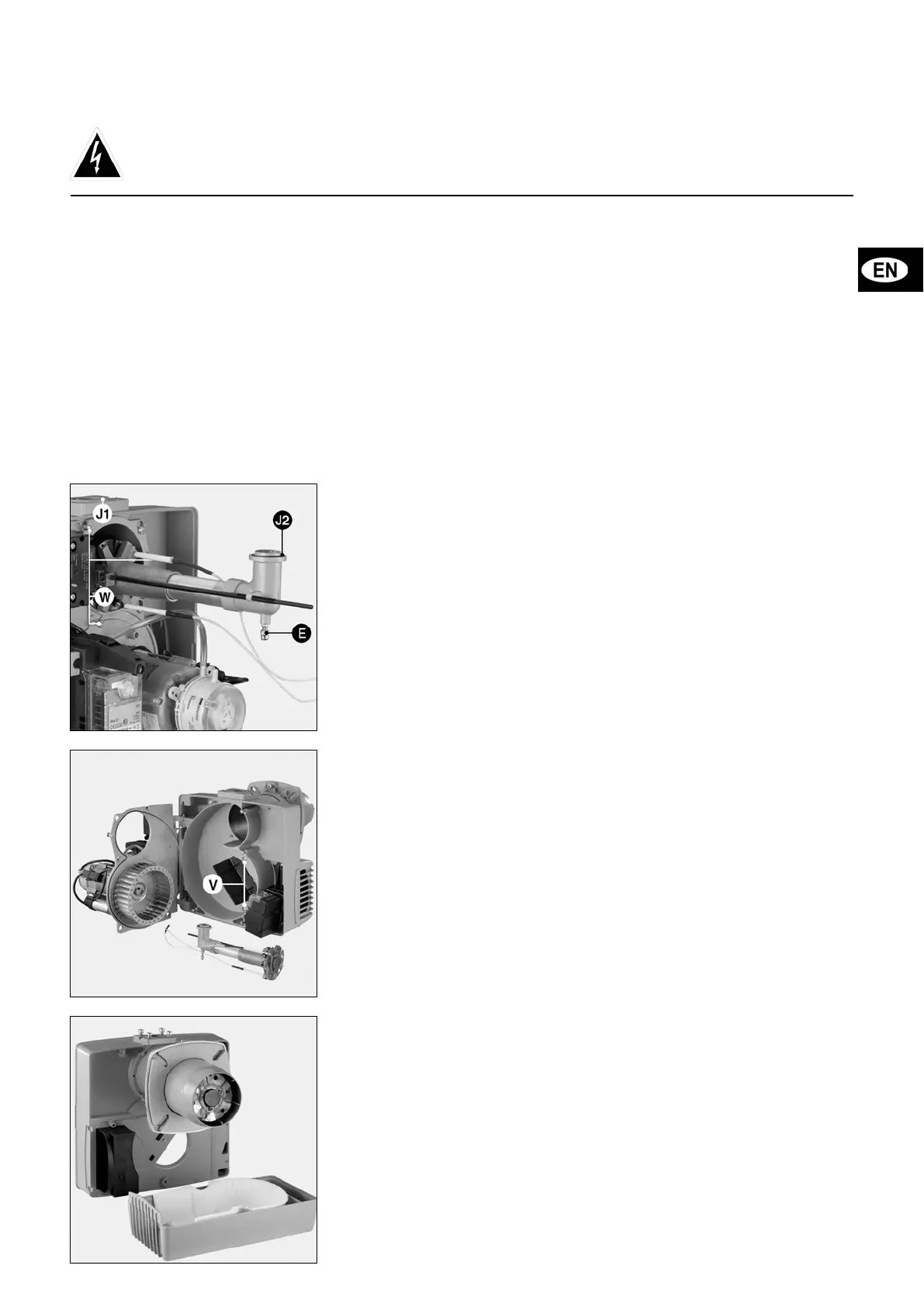

• Disconnect the ignition cable on the

transformer.

• Disconnect the ionisation sensor cable

on the cover.

• Remove the three screws W from the

cover.

• Fully release the lock nut of the gas

line by turning in a clockwise direction.

• Completely loosen spherical-head

screw E by turning in an anti-

clockwise direction.

• Remove the combustion head.

• Check the condition and the settings:

of the ignition electrode, the ionisation

probe, the turbulator and the diffuser.

• Change any defective parts.

• If necessary, remove any dust from the

parts that are accessible from the cover.

• When re-assembling, check for the

presence and the correct positioning

of the O-ring type sealing ring J2.

Cleaning the air box

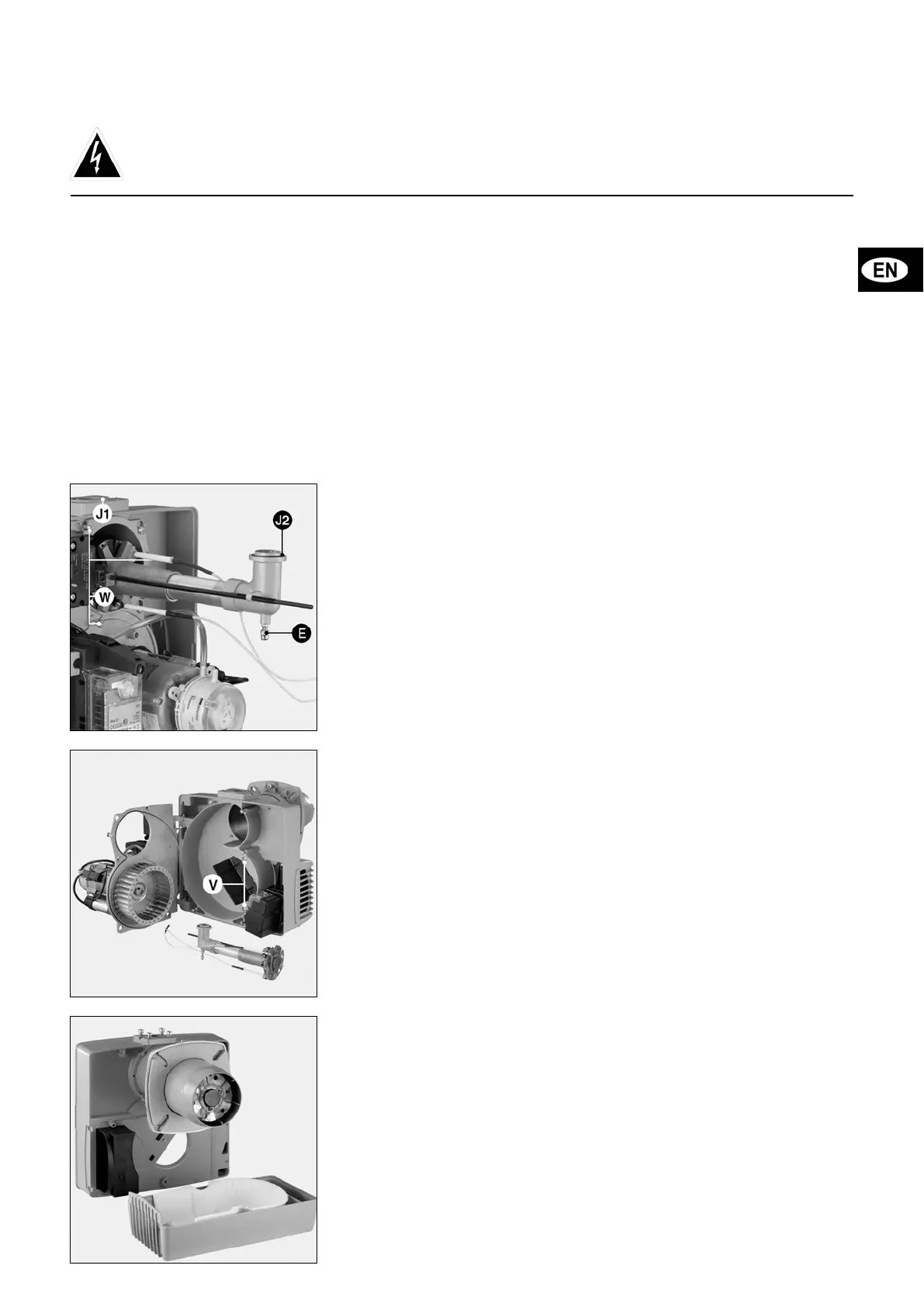

• Remove the two screws from the gas

manifold on the cover.

• Disengage the burner (bayonet) and

put it on the ground.

• Remove the two screws V from the

air box.

• Clean the air box and the acoustic

insulation foam.

• Remount the air box and the burner.

• Secure the gas manifold:

Check the presence and the

position of O-ring

J1

in the flange

on the housing.

• Check the tightness.

Cleaning the aeraulic circuit

• Remove combustion components.

• Disconnect motor.

• Remove all five motor plate screws,

starting from the bottom.

• Hook the plate on the cover.

• Clean the aeraulic circuit and the

turbine.

• Reassemble.

Important

The burner should be serviced at least

once a year by a trained specialist.

• Turn off power supply at isolator

switch.

• Check absence of voltage.

• Close gas input.

• Check for leaks:

Do not use pressurized liquids or

chlorinated products.

The setting values are indicated in the

paragraph:

“Start-up”

.

Use only original spare parts.

• Remove the burner cover.

Disassembling the connecting

nozzle.

• Disconnect flange 7P.

• Remove the two screws from the gas

ramp on the housing.

• Unscrew the bracket screw.

• Remove the burner and place it on the

ground.

• Loosen the four screws for the

connecting nozzle by five turns and

remove the connecting nozzle.

• Replace, index and secure the

connecting nozzle.

• Reassemble all parts in the reverse

sequence to disassembly.

• If required, fill space between the quarl

and the new blast tube with refractory

material.

• Check for leaks later.

Checking gas filter

The external or valve filter must be

examined at least once a year and filter

element changed if filthy.

• Remove cover screws.

• Remove filter element. Make sure no

dirt is left in its housing.

• Install a new, similar element.

• Replace seal, cover and screws.

• Open quarter-turn fuel hand-operated

valve.

• Check airtightness.

• Check combustion.

Gas valves

These valves do not require any special

maintenance.

No repairs may be carried out on them.

Faulty valves must be replaced by a

technician, who will then recheck air/

water tightness, performance and

combustion.

Checking connections

On electrical plate, fan motor and

servomotor.

Cleaning cover

• Clean cover with a water and

detergent mixture.

• Place cover back on.

Note

After each maintenance operation:

• Check gas combustion under actual

working conditions (doors closed,

cover in place, etc.) and check all

circuits for possible leaks.

• Perform safety checks.

• Record results in the relevant

documents.

Loading...

Loading...