10/2007 - Art. Nr. 13 017 700B 7

Start-up

Preliminary checks / leakage test

Setting air pressure switch

Burner start up simultaneously involves

starting up installation by the fitter or his

representative; only they can guarantee

boiler house compliance with currently

accepted practices and regulations in

force.

The fitter must first be in possession of a

“certificate of gas fuel conformity ”

issued either by the approved body or

distributor and also have leak-tested and

drained pipework upstream from the

quarter-turn hand-operated valve.

Preliminary checks

• Check the following:

- nominal available voltage and

electrical frequency and compare

them with values found on

identification plate,

- polarity between phase and neutral

- previously tested earth wire

connection,

- lack of potential between neutral and

earth,

• Make sure there is no current.

• Close fuel valve.

• Read boiler and regulator

manufacturer service instructions.

• Check the following:

- boiler is full of pressurized water,

- circulator(s) work(s),

- valve(s) open,

- combustion air supply to the boiler

house and combustion product

exhaust pipe are working correctly

and compatible with burner capacity

and fuel,

- electrical protection equipment

outside burner are present,

calibrated and set,

- boiler regulator circuit is set.

- gas type and distribution pressure

are suited to the burner.

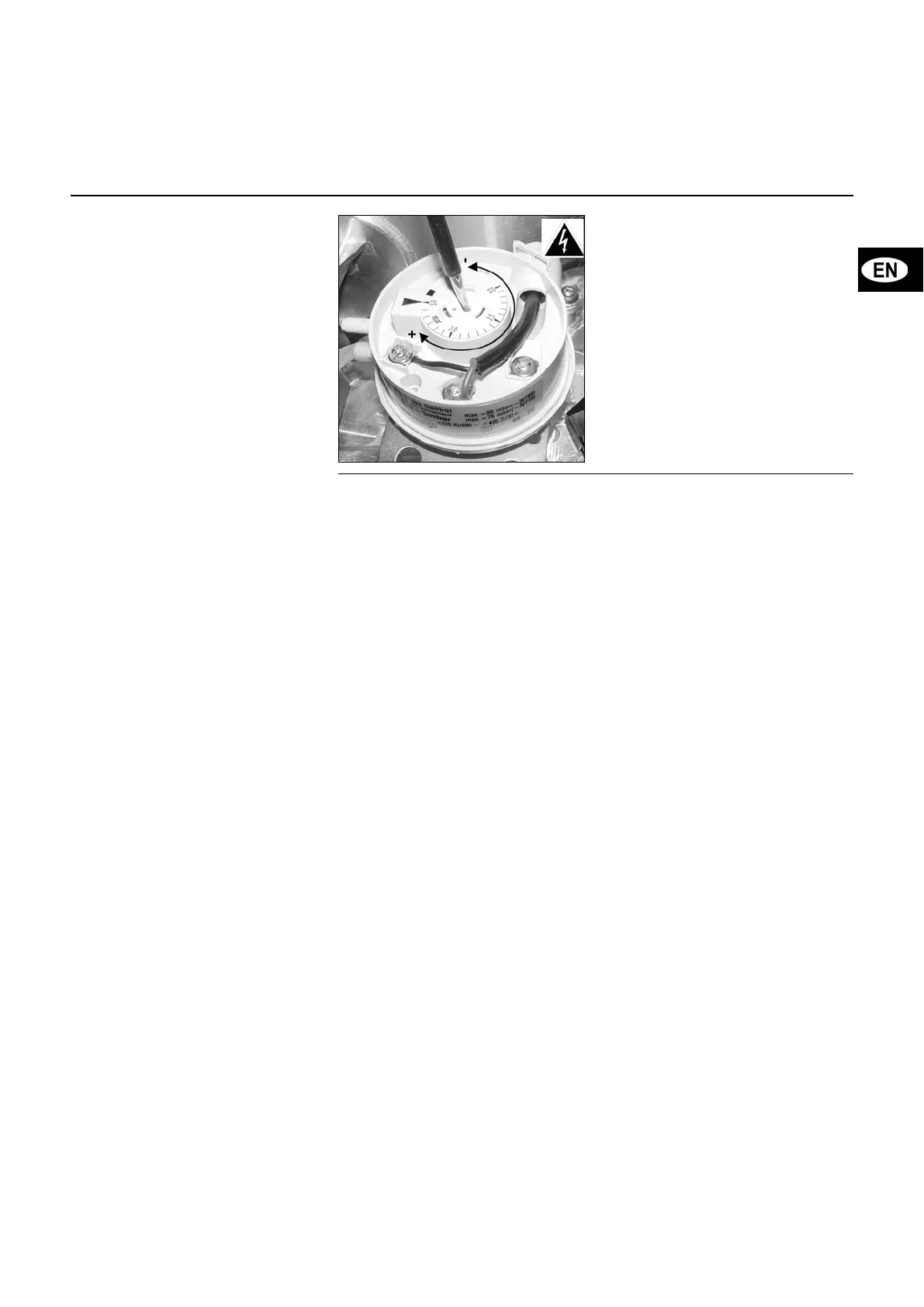

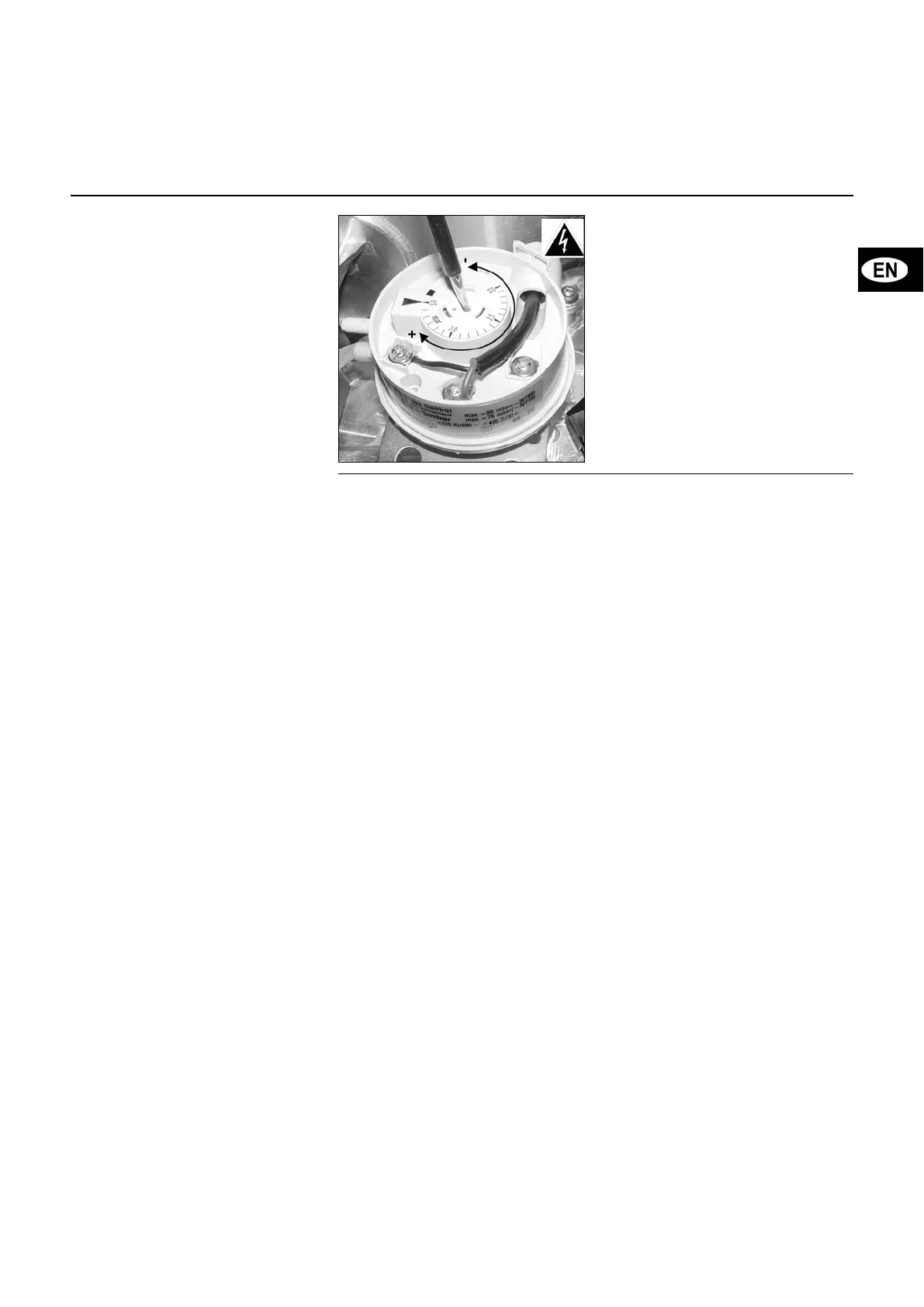

Setting air pressure switch

• Check the connection of the flexible

piping of the pressure tap on the + of

the pressure switch.

• Remove transparent cover. Unit

includes a index and graduated

mobile disk.

• Provisionally set pressure controller to

the minimum value shown on

graduated disk.

Leakage test

• Connect a pressure gauge to pressure

take-off located upstream from gas

manifold.

• Open quarter-turn hand-operated

valve.

• Check supply pressure.

• Use a purpose designed medium to

check air-tightness of gas manifold

connections, including external filter.

No leak should be found.

• Vent the pipe downstream of the

manual valve by a quarter of a turn

whilst protecting the gas valve inlet.

• Reclose drain valve.

Loading...

Loading...