10/2007 - Art. Nr. 13 017 700B8

Start-up

Checking and setting

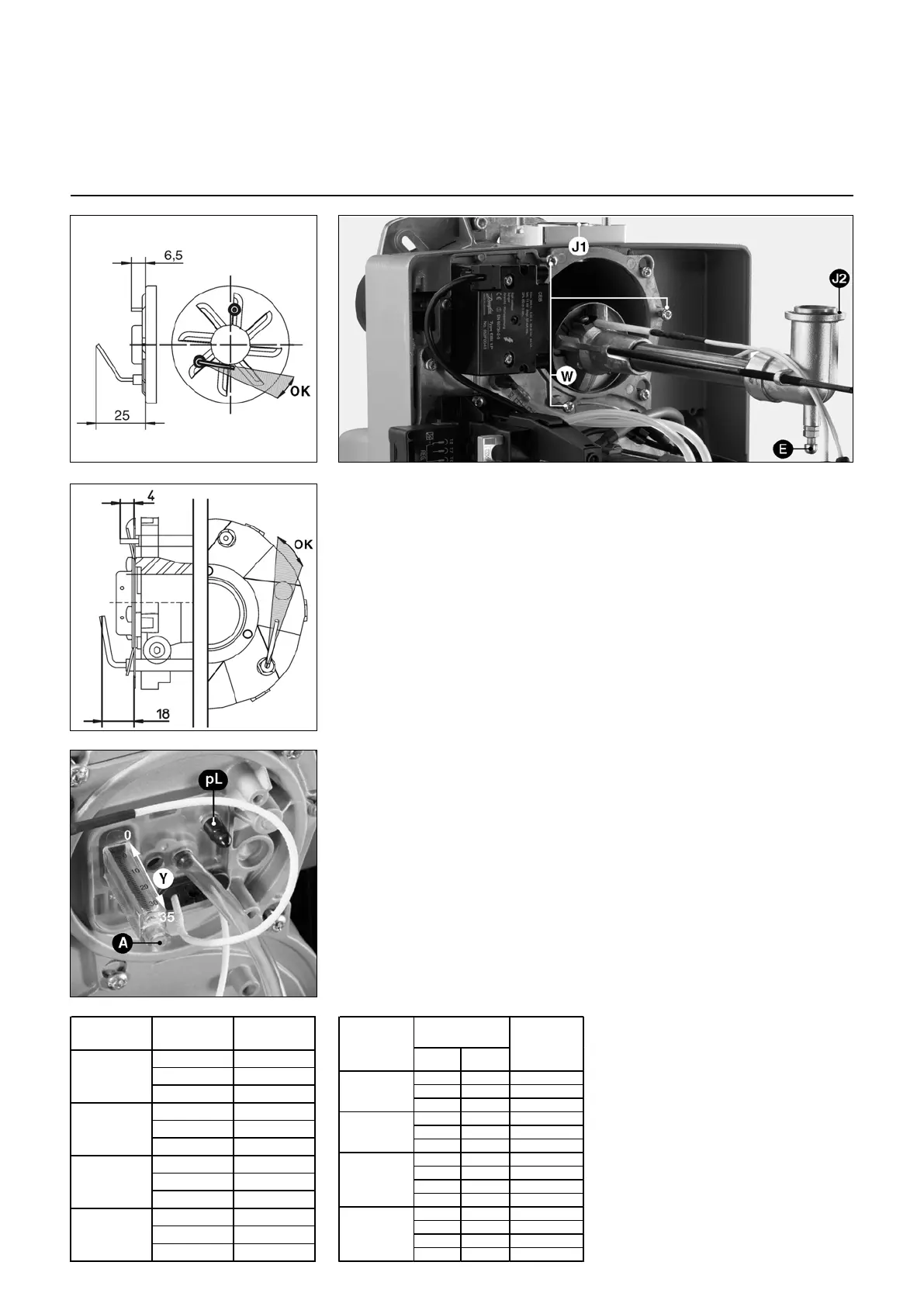

Combustion head, secondary air

NC16/NC21

NC12

Checking and setting combustion

head

Burner is supplied already set for natural

gas.

• Check positions of ignition electrode

and ionisation sensor as per the

drawings enclosed.

• During assembly, check that O-ring J2

is fitted and correctly positioned.

• Unscrew spherical-head screw E

(clockwise) to secure the head.

• Fit the grommet onto the cover.

• Fasten the cover (3 screws W).

• Tighten the ignition cable and connect

it to the transformer.

• On the cover, connect the connection

box’s integral ionisation cable.

• Check the assembly is airtight.

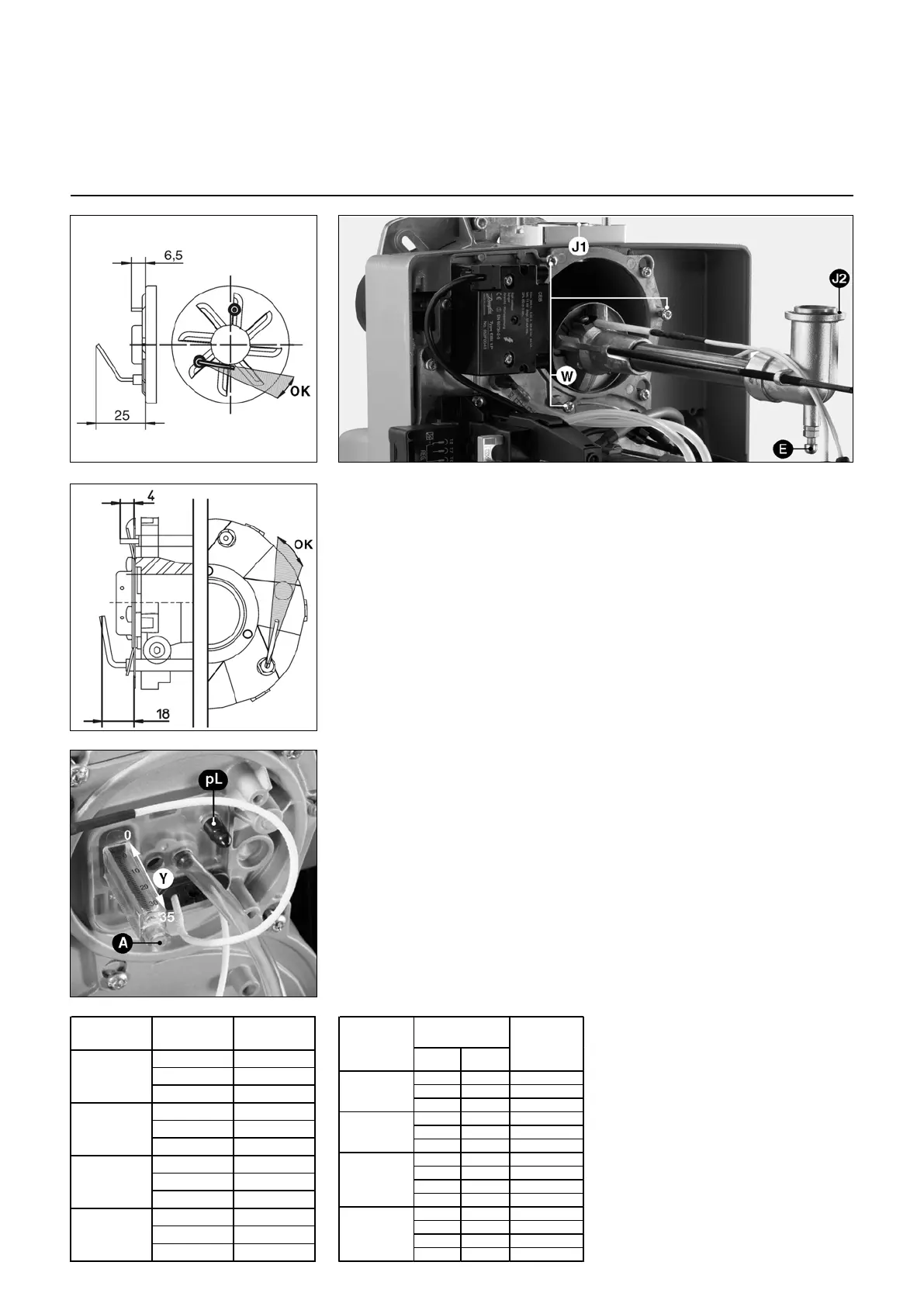

Secondary air

This is the amount of air flowing between

the turbulator diameter and blast tube.

Turbulator position (dimension Y) is read

on a template 0 to 35mm scale.

Maximum secondary air is set at 35 and

minimum at 0.

According to the following:

- requested power output

- firing quality (shock, vibration, judder,

time lag),

- combustion quality,

this value can be changed.

Setting

This is performed without removing

burner, whether stopped or in operation,

according to enclosed values.

By reducing dimension Y (in a cw

direction), CO

2

increases and vice

versa.

• Turn screw A in the direction desired.

1-stage

burners

Burner

Loading...

Loading...