CVC TECHNOLOGIES, INC. CVC 400 OPERATION MANUAL

16 - 2

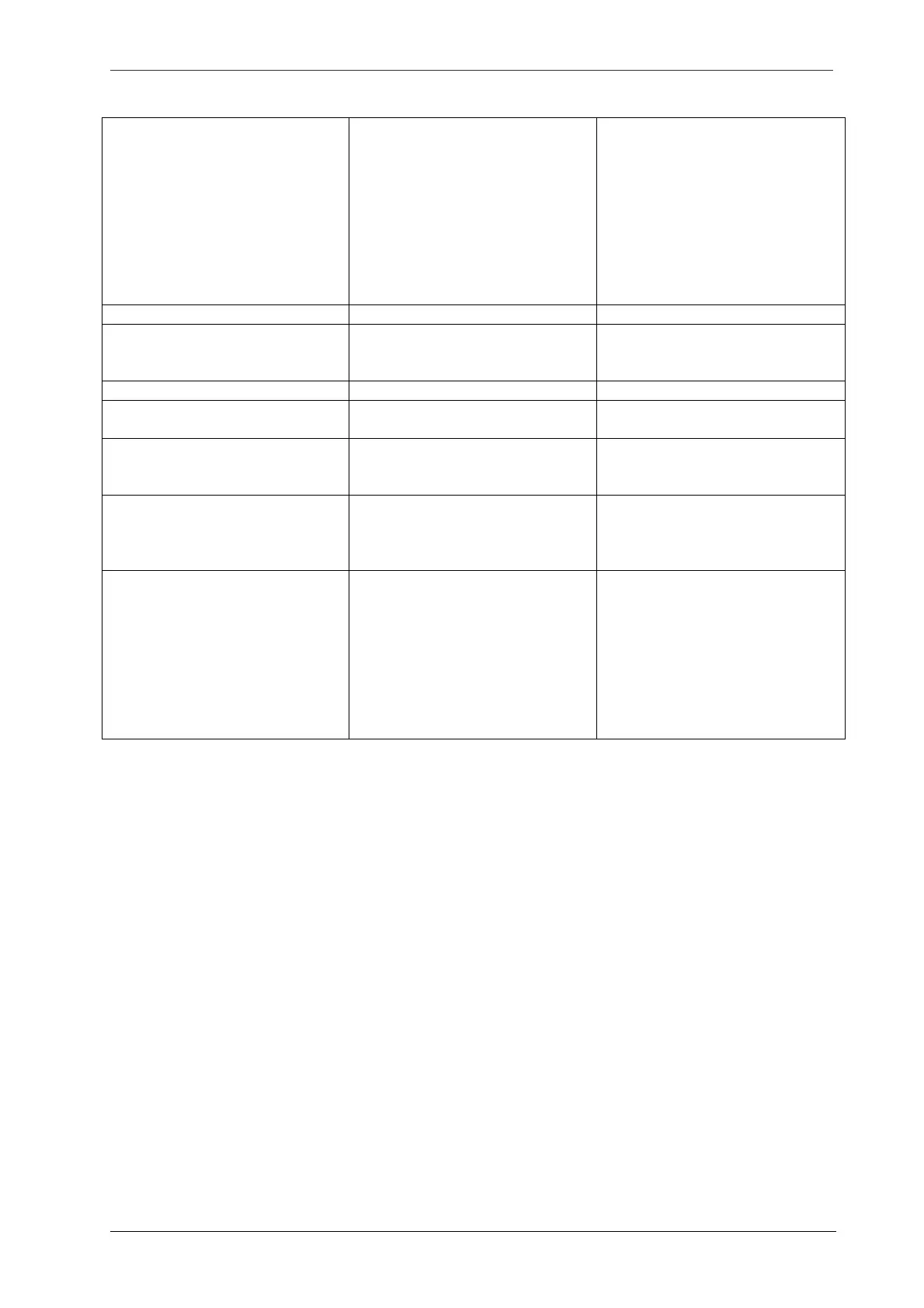

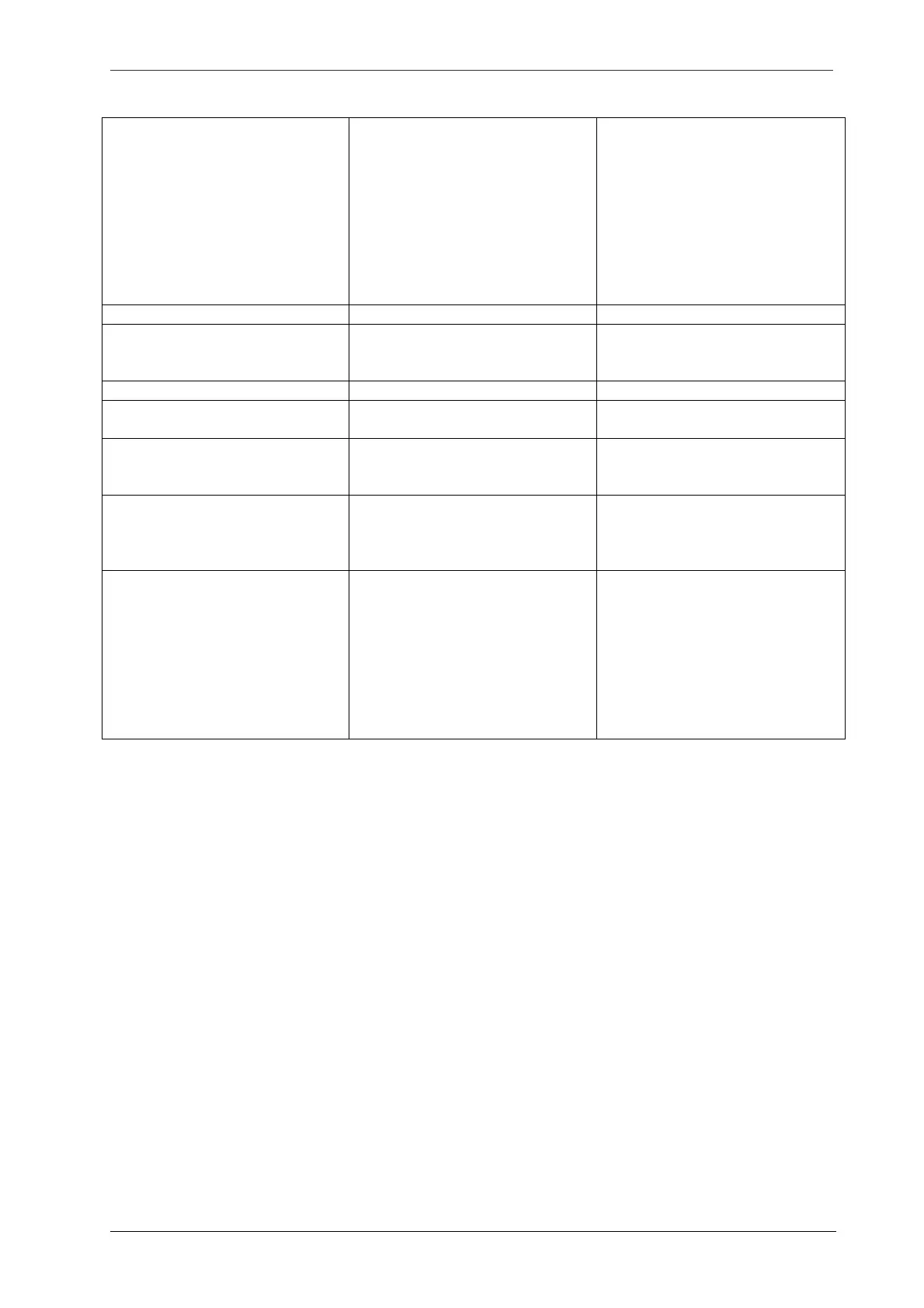

4. Two labels dispensed at a time

a. The sensitivity values of the labels

and the backing papers are too

close. This will cause no signal is

sent to stop it.

b. The red light of the label sensor

does not exactly emit on backing

paper.

c. Some transparent products may

make product sensor detect the

same product repeatedly.

a. Increase label sensitivity value.

b. Properly adjust emitting point.

c. Properly adjust product sensor.

5. Missing label Improper product spacing (too close)

Increase product spacing.

6. Wrinkle label a. Too fast label dispensing speed

b. Label position too rightward

c. Irregular product shape

a. Decrease label dispensing speed.

b. Adjust labeling position leftward.

c. Ask supplier to correct.

7. Label front curl Too leftward label position Adjust labeling position rightward.

8. Backing paper is pulled out by the

product.

Too slow label dispensing speed Increase label dispensing speed.

9. Abnormal noise is heard during

labeling motor is running.

a. Too fast labeling speed makes

stepper motor overload

b. Insufficient product spacing

a. Slow down labeling speed

b. Increase product spacing

10. Both label sides (left and right) are

not aligned.

a. Irregular product causes incorrect

emitting point.

b. Transparent products may cause

incorrect product detection.

a. Perform detecting point

adjustments.

b. Decrease product sensor sensitivity.

11. Label is dispensed repeatedly

a. The measured sensitivity values of

backing paper and labels are too

close, or the value of backing paper

is higher than the setting values.

b. Label web is not properly placed in

the label sensor slot.

c. Clear label is applied

d. Label edge is exactly placed in the

label sensor slot.

a. Check and make sure the label

sensitivity value is higher than the

backing paper’s by 30.

b. Check and ensure label web is

correctly placed in the sensor slot.

c. Use clear label sensor

d. Increase label dispensing length.

Loading...

Loading...