CVC TECHNOLOGIES, INC. CVC 400 OPERATION MANUAL

11. MACHINE SET-UP AND ADJUSTMENT

For personnel safety and avoiding machine damage, always SWITCH OFF the power before

any machine adjustment.

All machine adjustments should be accomplished by qualified technicians.

Most adjustable parts of the machine are provided with guide rulers or numerical hand

wheels, proper adjustments are determined through factory test and should not be changed

unless necessary. Therefore some of the sections provided in this chapter are only for

reference.

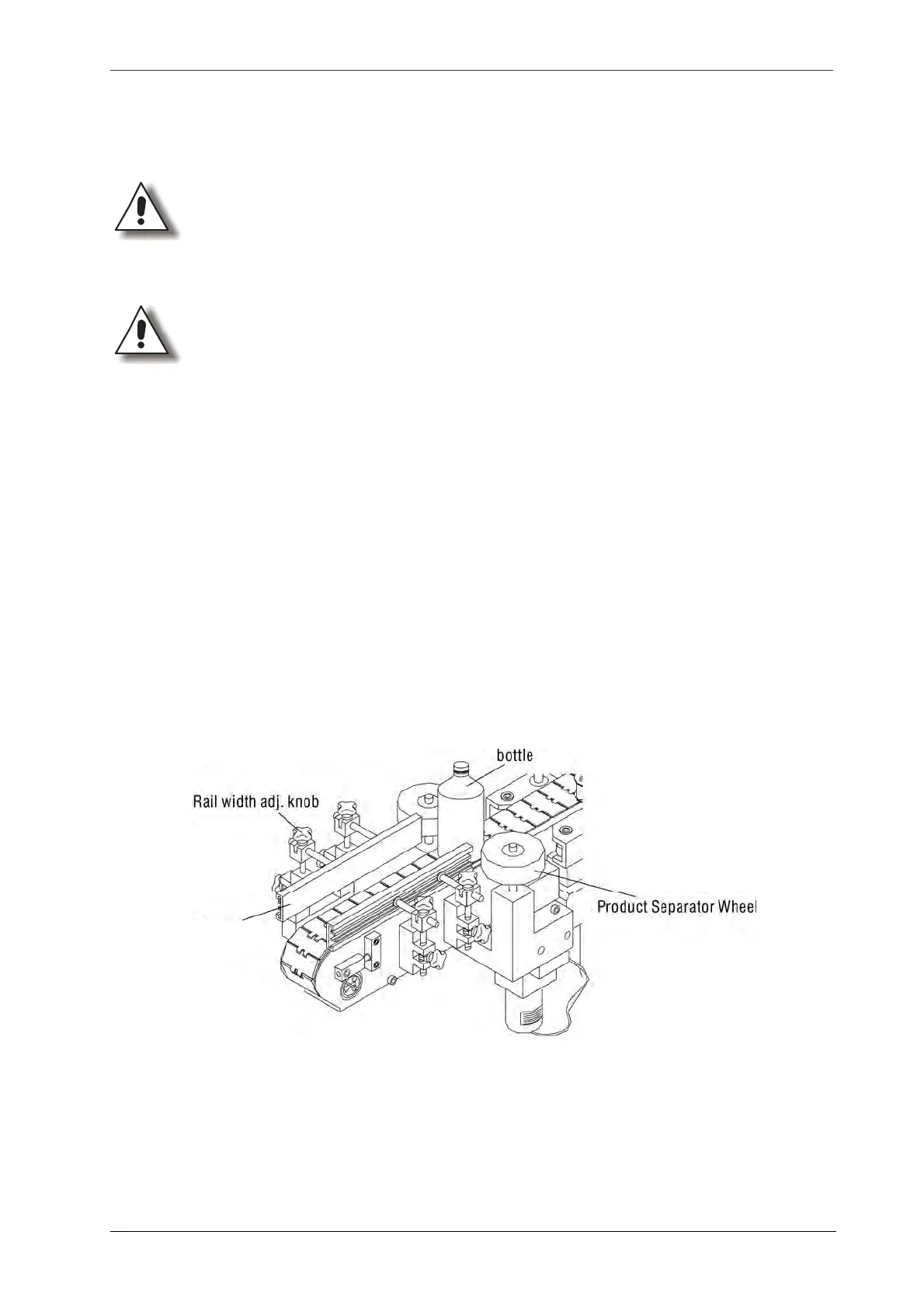

11.1 Guide Rail and Product Separator Wheel Adjustments

a. Place a product onto the conveyor, and loosen the guide rail width knob. Adjust all guide rails

according to the product width, allowing the product to move freely on the conveyor.

b. The guide rails (plates) will lead the product to make contact with the separator wheels to create a

proper spacing between products for correct wrap-around labeling.

c. The two product separator wheels are standard equipment. Infeed twin feed screw units (optional)

are recommended for higher speed applications where changeover is less frequent.

Guide rail

plate

Fig 11.1-1

11 - 1

Loading...

Loading...