CVC TECHNOLOGIES, INC. CVC 400 OPERATION MANUAL

16 - 3

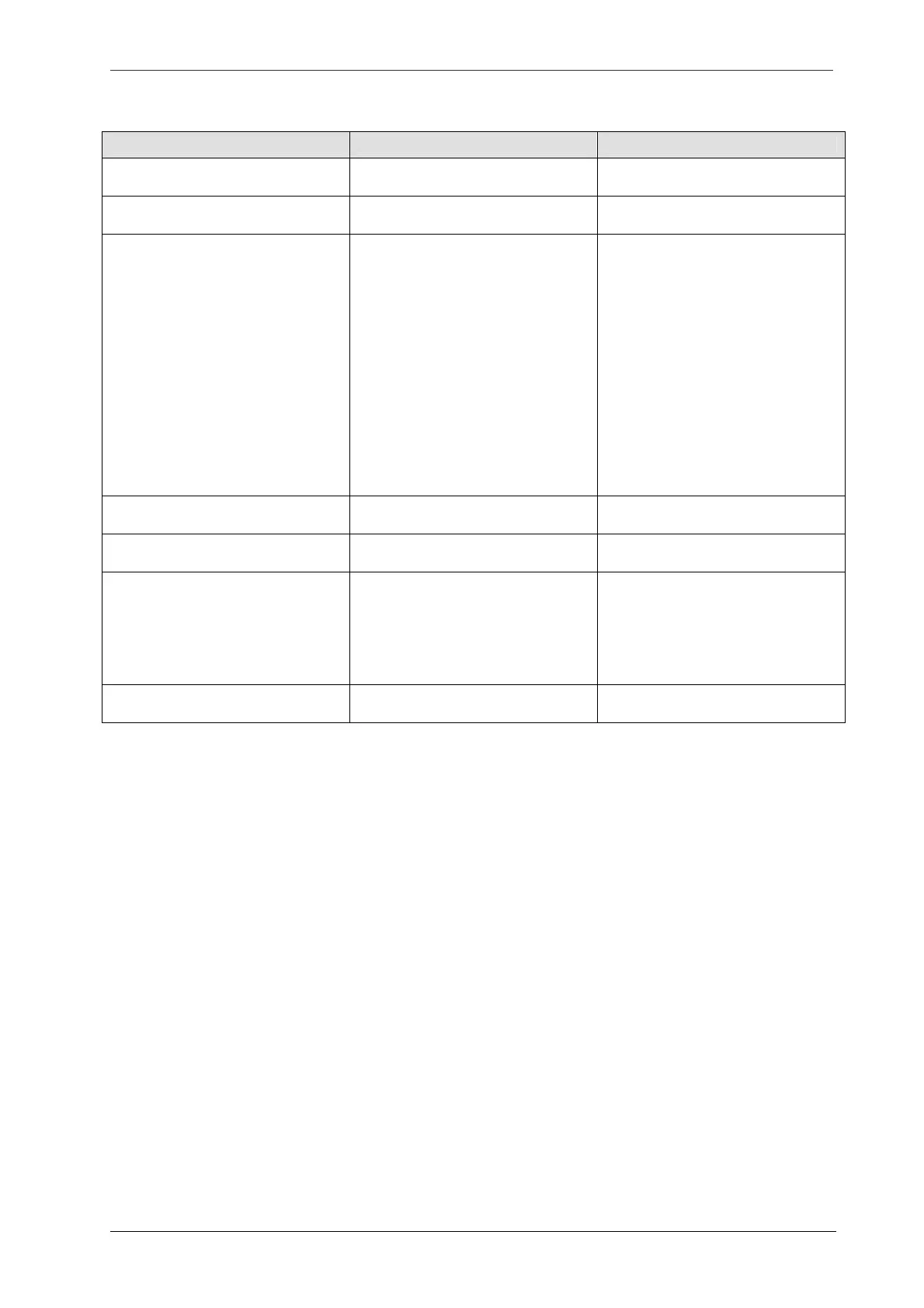

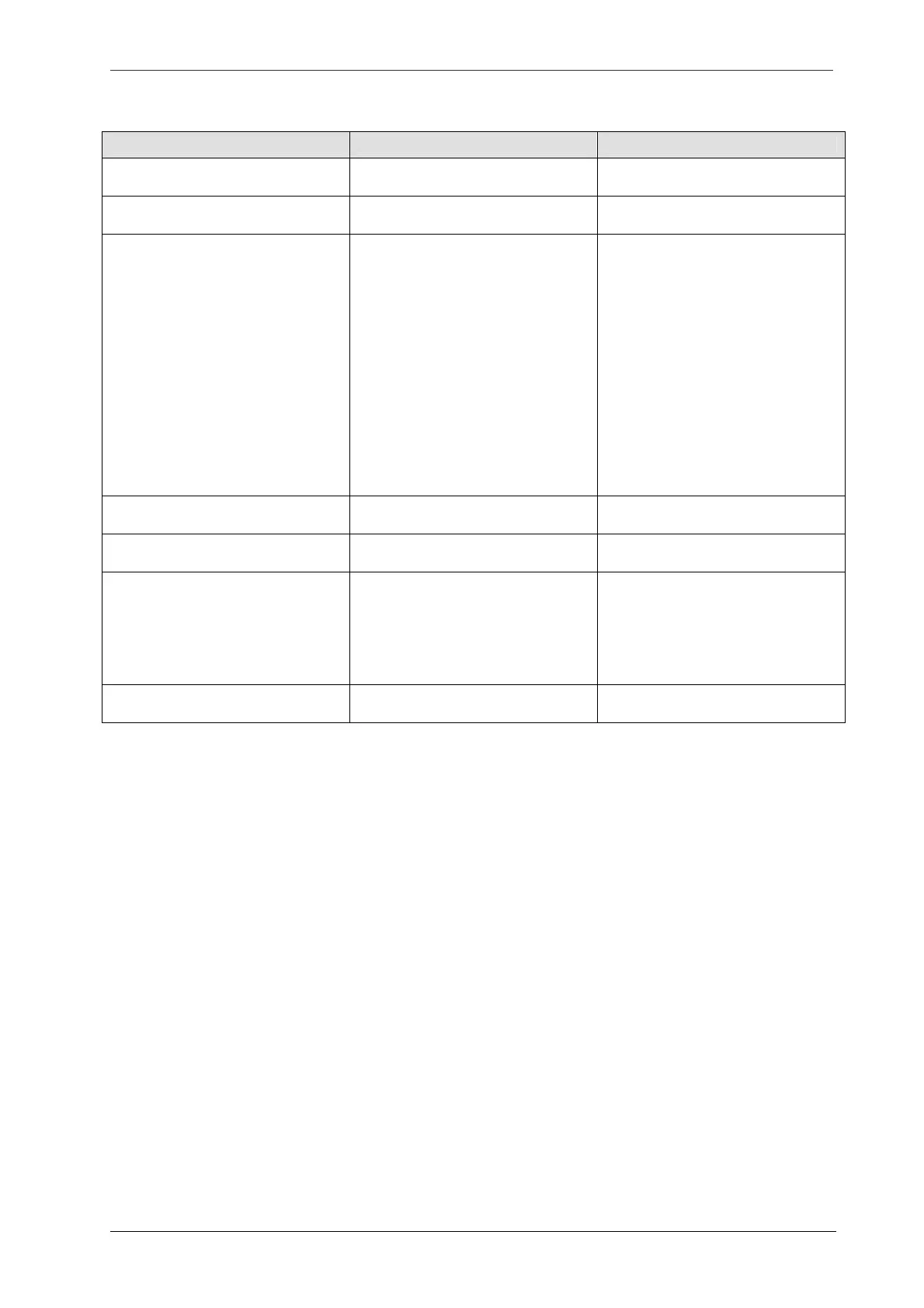

16.2 Troubleshooting for C60 Hot Stamp Printer

Problem Possible Cause Suggested Solution

1. Heating indicator keeps ON

(orange), fail to OFF (green).

Heater malfunction Replace with a new heater.

2. Thermal indicator keeps on (red) or

flashing.

Thermal IC malfunction Replace with a new thermal IC.

3. Unclear printing a. Check if the hot stamp silicone pad

is worn.

b. Insert two or three pieces of paper

behind the label to check if the

silicone pad is good. Press test

button to check the printing. If clear,

indicating the distance is too far.

c. Poor quality of hot stamp ribbon.

d. Ribbon fails to advance forward.

e. Ribbon print face is mounted

reversely.

f. The ribbon ink fails to print on the

label surface.

a. Replace with a new silicone pad if

necessary.

b. Decrease the distance between the

type chase and the hot stamp

silicone pad.

c. Try another ribbon.

d. Check the air cylinder of the ribbon

advance.

e. Properly remount it in a correctly

direction.

f. Replace label material.

4. The printing is unclear on the left

side but clear on the right side.

Insufficient ribbon advance makes

printing overlap.

Adjust ribbon advance to make a

proper stroke.

5. The type position is drifted. The fastening screw of the hot stamp

printer is loose.

Tighten the screws.

6. Printing is too thick or distorted. a. The distance between the brass type

and the hot stamp silicone pad is

too close.

b. Print time too long

c. Print temperature too high

a. Move type chase to increase the

distance between type chase and

hot stamp silicone pad.

b. Shorten printing time.

c. Check temperature controller, and

lower printing temperature.

7. Unstable printing performance

a. Ink spread

b. Faint printing

a. Lower printing temperature

b. Increase printing temperature

Loading...

Loading...