CVC TECHNOLOGIES, INC. CVC 400 OPERATION MANUAL

11. 4 Label Peel Blades Adjustments (Head A and Head B)

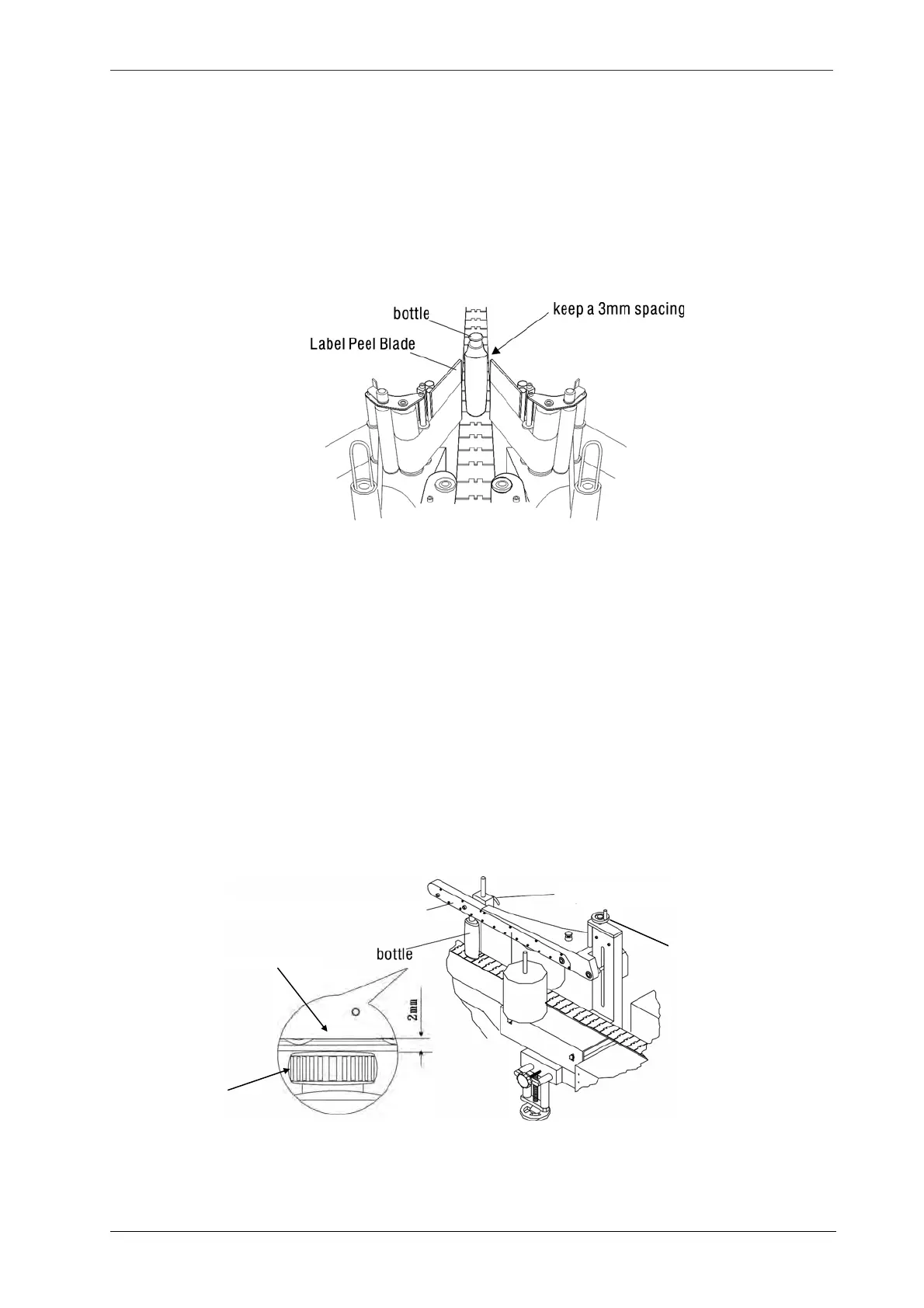

Adjust the spacing between the two label-peel blades and the product for proper labeling.

a. Place a product on the conveyor between the two label peel blades.

b. Rotate the lateral adj. knob (Fig 11.3-1) to move the label head blade to allow a 1/8" (3mm) space

between the product and the each peel blade (Fig 11.4-1).

Fig

11.4-1

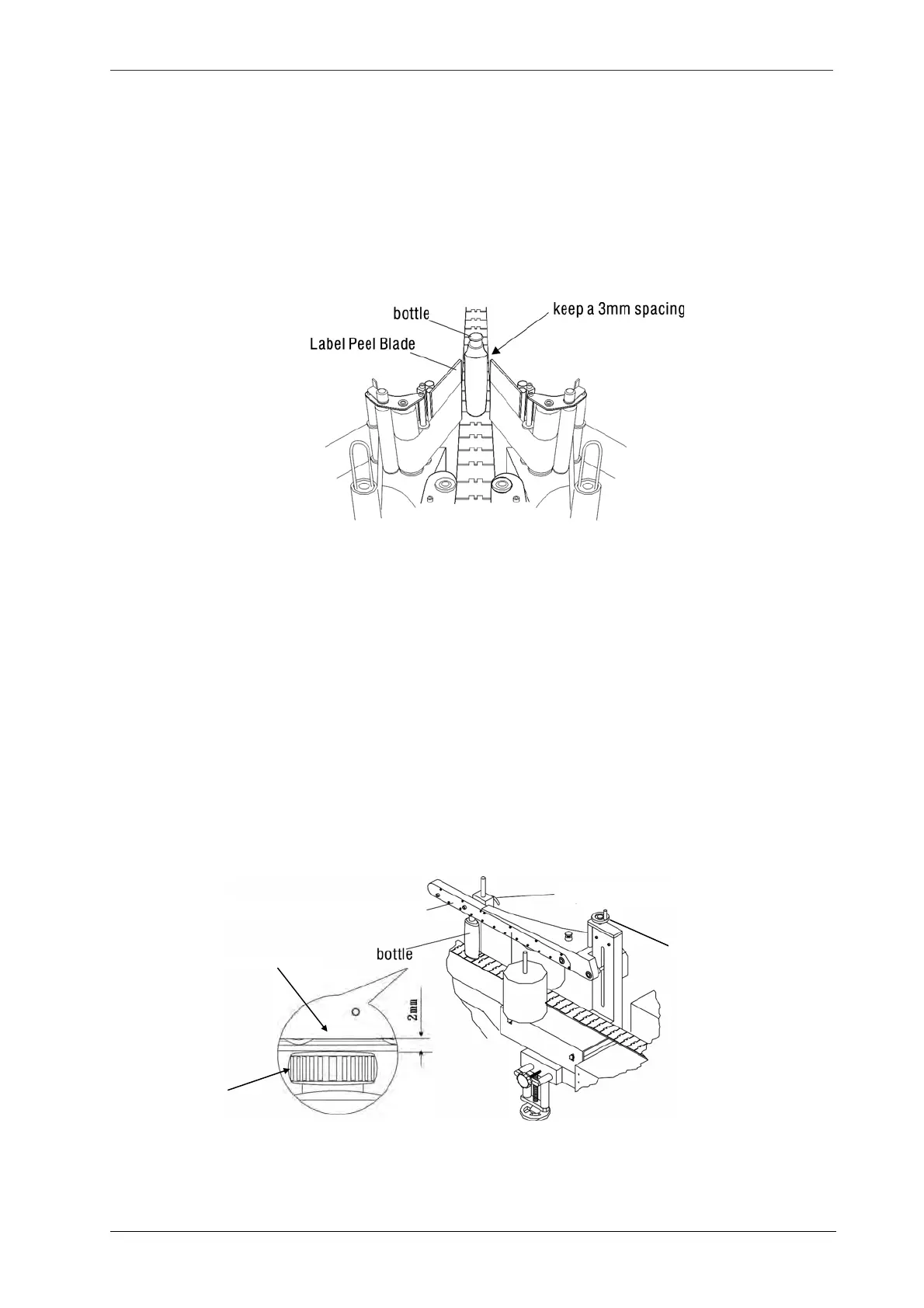

11.5 Top Hold-Down Mechanism Adjustments

The top hold-down bar is to prevent the product swaying during labeling; the swaying product would

make improper label placement. The adjustment procedures are illustrated as follows.

a. Place a product under the hold-down bar (Fig 11.5-1).

b. Loosen the L-type fastening lever and then rotate the height adj. handwheel to adjust the height of

the hold-down bar. The belt of the hold-down bar should touch the bottle cap in a depth of 2mm for

stable and secure labeling.

c. Tighten the L-type fastening lever after adjustments.

Height adj. handwheel

Fastening lever

Top hold-down ba

To

hold-down ba

Cap

Fig

11.5-1

11 - 3

Loading...

Loading...