CVC TECHNOLOGIES, INC. CVC 400 OPERATION MANUAL

13 - 1

13. MAINTENANCE

13.1 General Precautions

a. Safety

․Before performing any maintenance job or cleanup, ensure that the power is disconnected.

․Always take the necessary safety measures to protect both machine and personnel when carrying

out maintenance job

b. Machine Clean-u

Use a damp fabric to clean the machine parts; do not wash directly with water. For tough dirt,

moderate flammable products can be used (such as solvent, alcohol for industrial use …etc.), avoid

using highly corrosive or inflammable products (such as methane or thinner …etc.)

c. Spare Parts Replacement

Regularly check the machine for damaged or worn out parts and have them replaced if necessary.

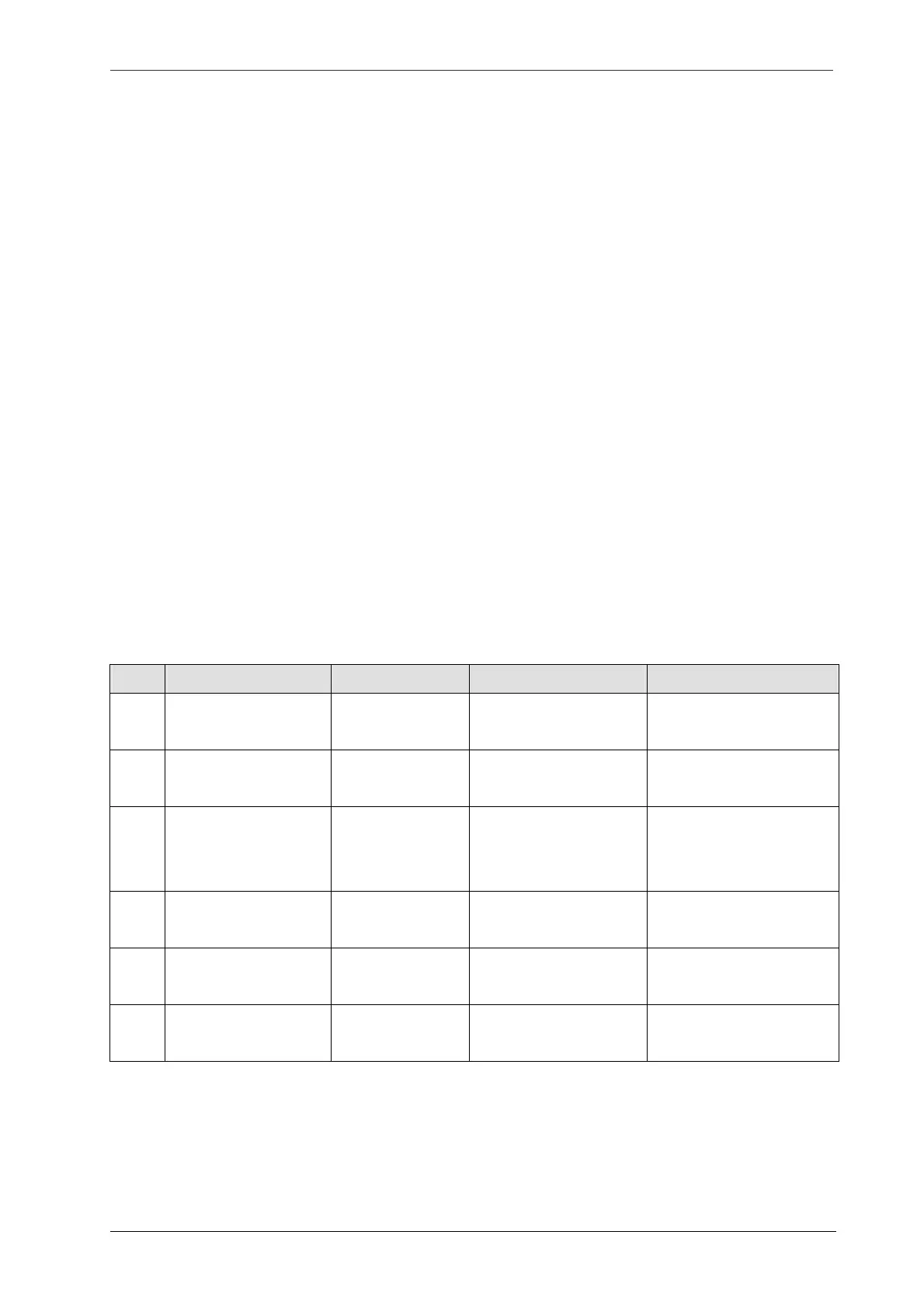

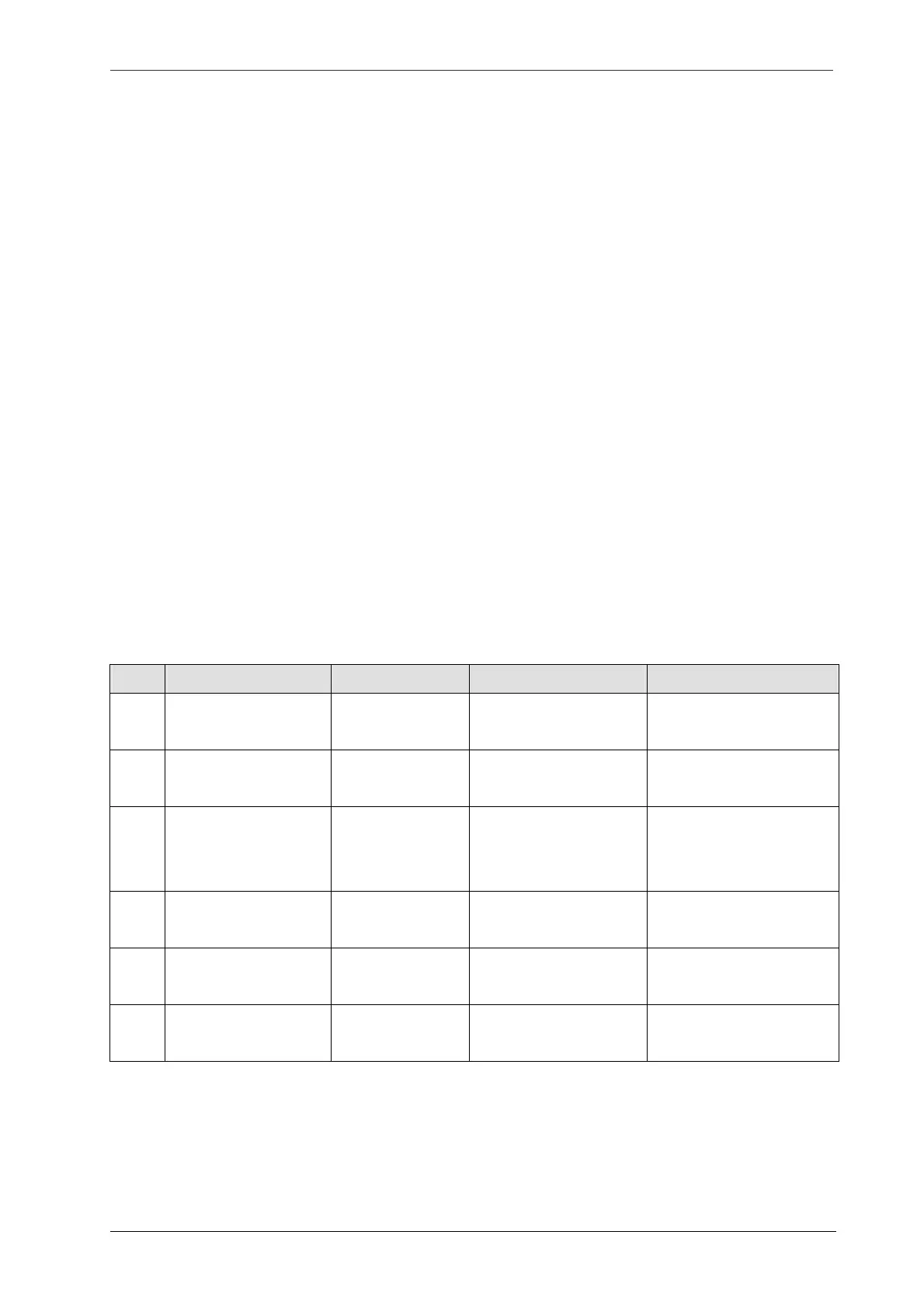

13.2 Maintenance and Lubrication Schedule

No. Machine parts Maintenance Period Remarks

1 Labeling head height adj.

screw

Lubrication

(ISO VG 32)

Weekly Wipe out old grease and apply

new grease.

2 Label head horizontal adj.

screw

Lubrication

(ISO VG 32)

Weekly Wipe out old grease and apply

new grease.

3 Hot stamp printer

horizontal adj. screw

(Optional)

Lubrication

(ISO VG 32)

Weekly Wipe out old grease and apply

new grease.

4 Hot stamp printer height

adj. screw (Optional)

Lubrication

(ISO VG 32)

Weekly Wipe out old grease and apply

new grease.

5 Air regulator

(Option)

Water draining After every usage Drain water before and after

every usage

6 Machine appearance Cleaning After every usage Cleaning the machine before

and after every usage.

Loading...

Loading...