•

•

•

•

Specify the following for each event:

Maintenance item (for example, motor bearings).

Maintenance action (for example, replacement).

Maintenance time base (for example, running hours, or a specific date and time).

Maintenance time interval or the date and time of next maintenance.

N O T I C E

To disable a preventive maintenance event, set the associated parameter 23-12 Maintenance Base to [0] Disabled.

Preventive maintenance can be programmed from the LCP, but use of the PC-based VLT® Motion Control Tool MCT 10 is recom-

mended.

+

+

+

+

+

+

+

+

+

+

+

+

+

+

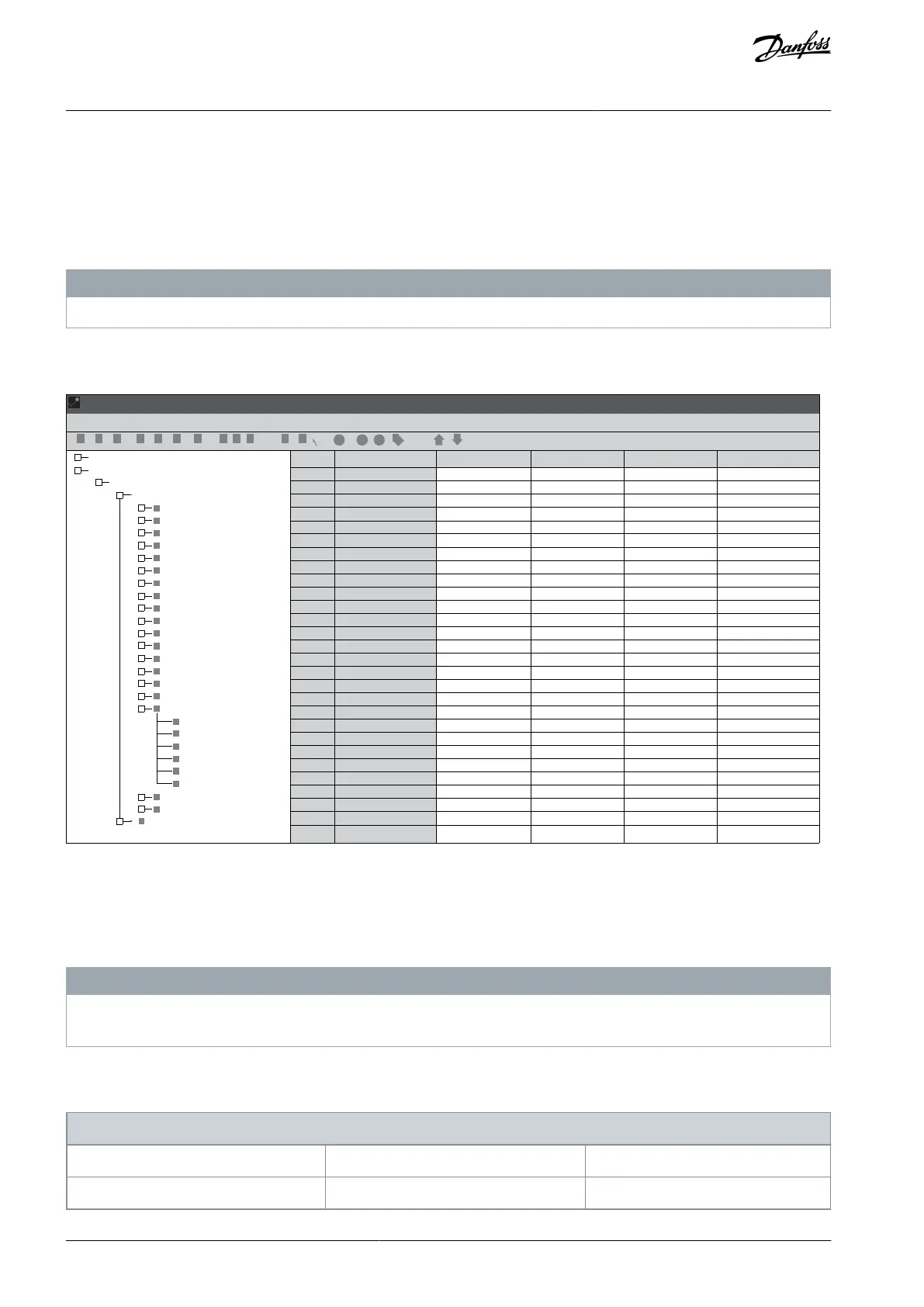

Un titled - MC T 10 SE T - up S of t w ar e

F ile E dit V iew I nser t C ommunica tion T ools Options Help

ID Name S etup 1 S etup 2 S etup 3 S etup 4

2310.0 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.1 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.2 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.3 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.4 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.5 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.6 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.7 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.8 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.9 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.10 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.11 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.12 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.13 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.14 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.15 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.16 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.17 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.18 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2310.19 M ain t enanc e I t em M ot or bear ings M ot or bear ings M ot or bear ings M ot or bear ings

2311.0 M ain t enanc e A c tion L ubr ica t e L ubr ica t e L ubr ica t es L ubr ica t e

2311.2 M ain t enanc e A c tion L ubr ica t e L ubr ica t e L ubr ica t es L ubr ica t e

2311.3 M ain t enanc e A c tion L ubr ica t e L ubr ica t e L ubr ica t es L ubr ica t e

2311.4 M ain t enanc e A c tion L ubr ica t e L ubr ica t e L ubr ica t es L ubr ica t e

2311.5 M ain t enanc e A c tion L ubr ica t e L ubr ica t e L ubr ica t es L ubr ica t e

2311.6 M ain t enanc e A c tion L ubr ica t e L ubr ica t e L ubr ica t es L ubr ica t e

Net w or k

P r ojec t

VL T A QU A DRIVE

A ll P ar amet ers

Br akes

R ef er enc e / R amps

Limits / W ar nings

Dig ital I n/O ut

A nalog I n/O ut

C omm. andOptions

Smar t log ic

Special F unc tions

Dr iv e I nf or ma tion

Da ta R eadouts

I nf o & R eadouts

Dr iv e Closed L oop

Ex t . Closed L oop

A pplica tion F unc tions

T ime -based F unc tions

T imed A c tions

M ain t enanc e

M ain t enanc e R eset

Ener gy L og

T r ending

P a yback C oun t er

C ascade C on tr oller

W a t er A pplica tion F unc tions

C ascade C on tr oller

Illustration 95: Maintenance Menu, MCT 10

The LCP indicates (with a wrench icon and letter M) when it is time for a preventive maintenance action and can be programmed to

be indicated on a digital output in parameter group 5-3* Digital Outputs. The preventive maintenance status is shown in parameter

16-96 Maintenance Word. A preventive maintenance indication can be reset from a digital input, the FC bus, or manually from the

LCP through parameter 23-15 Reset Maintenance Word.

N O T I C E

The preventive maintenance events are defined in a 20-element array. Hence, each preventive maintenance event must use the

same array element index in parameter 23-10 Maintenance Item to parameter 23-14 Maintenance Date and Time.

Parameter 23-10 Maintenance Item

Table 1028: Parameter 23-10 Maintenance Item

Default value: [1] Motor Bearings

Parameter type: Option, Array [6]

Change during operation: True

AU275636650261en-000101 / 130R0334558 | Danfoss A/S © 2022.12

Parameter Descriptions

VLT AutomationDrive FC 301/302

Programming Guide

Loading...

Loading...