Make the screen connections with the largest possible

surface area (cable clamp). This is done by using the

supplied installation devices within the frequency

converter.

Cable-length and cross-section:

The frequency converter has been EMC tested with a given

length of cable. Keep the motor cable as short as possible

to reduce the noise level and leakage currents.

Switching frequency:

When frequency converters are used together with Sine-

wave filters to reduce the acoustic noise from a motor, the

switching frequency must be set according to the

instruction in 14-01 Switching Frequency.

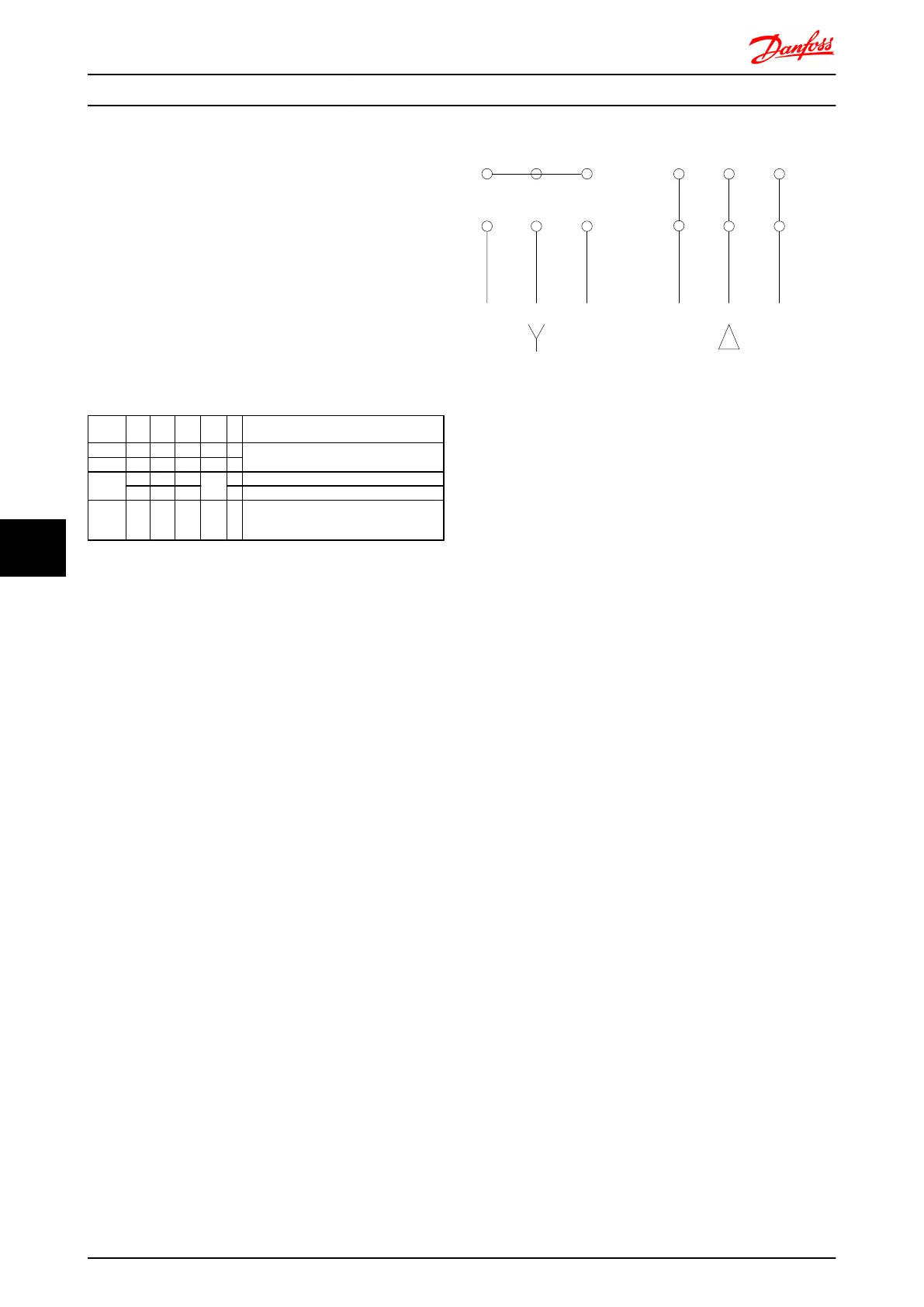

Term.

no.

96 97 98 99

U V W

PE

1)

Motor voltage 0-100% of mains voltage.

3 wires out of motor

U1 V1 W1

PE

1)

Delta-connected

W2 U2 V2 6 wires out of motor

U1 V1 W1

PE

1)

Star-connected U2, V2, W2

U2, V2 and W2 to be interconnected

separately.

1)

Protected Earth Connection

CAUTION

In motors without phase insulation paper or other

insulation reinforcement suitable for operation with

voltage supply (such as a frequency converter), fit a Sine-

wave filter on the output of the frequency converter.

U V W

175ZA114.10

VU W

96 97 98

96 97 98

Electrical Installation FC 300 Design Guide

170 MG.33.BD.02 - VLT

®

is a registered Danfoss trademark

88

Loading...

Loading...